Absoger

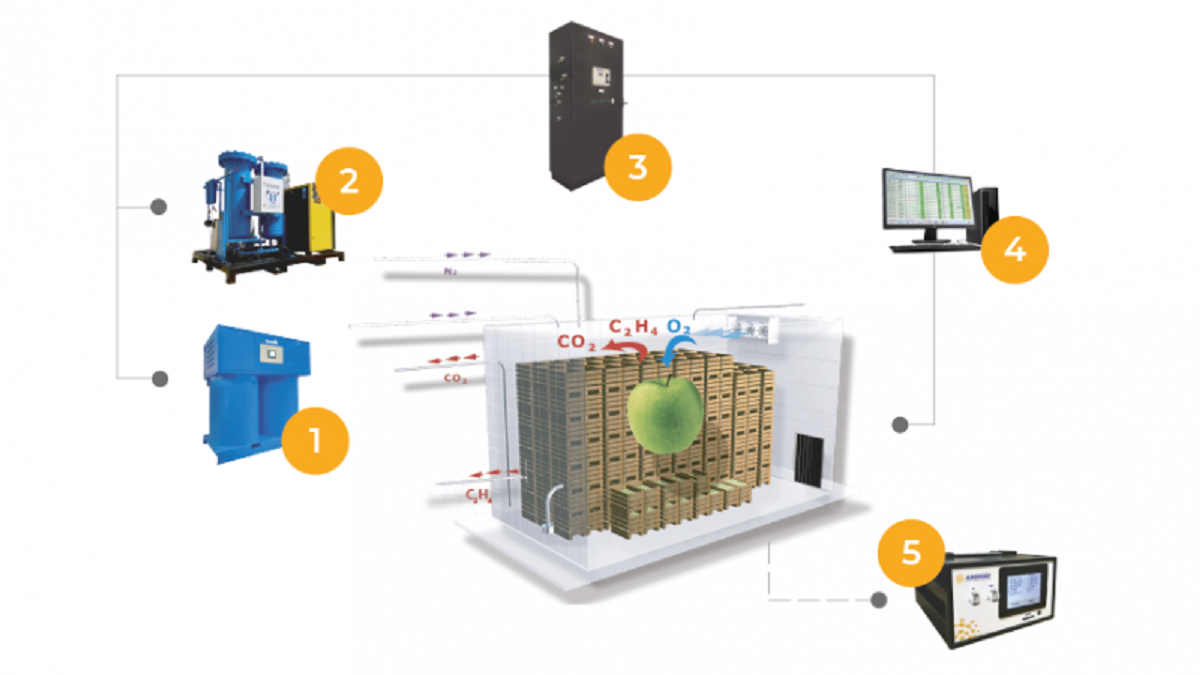

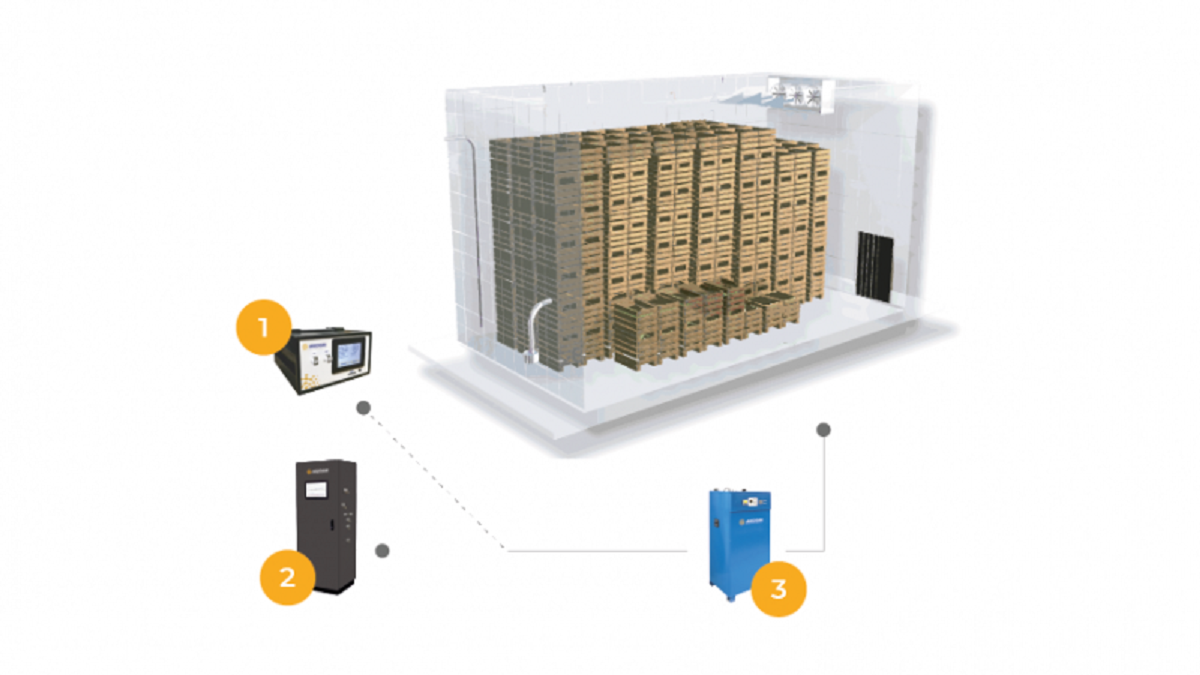

Cooling and CA , Measurements

Controlled Atmosphere allows to extend the blueberry season

Lelclerc et al. demonstrated that even under adverse rainy season, CA (3 % O2 et 15 % CO2) delays rots development

Worldwide fresh blueberry (Vaccinium corymbosum) production has increased by 25% over the past 5 years, reaching 1,3 million tons. Higher upcoming volumes push the blueberry sector to work on its post- harvest practices to extend fruit’s lifespan and maintain a high-quality supply.

Currently, French producers mainly store in Regular air for less than 14 days.

Storage techniques & retail practices to improve shelf life

Different combinations of storage techniques (up to 21 days in Regular air and 48 days weeks in Controlled Atmosphere - CA) and retail practices were tested (traditional air temperature and open refrigerated display case).

Sensory and nutritional analysis were performed to address consumer concerns regarding long storage impact on blueberries quality.

Indicators were water loss and fruit loss percentage for warehouses, marketable fruit for retailers, sensory attributes and nutritional content evolution for consumers.

The protocol was based on professional practices.

This study aimed at demonstrating possible practical advances in post-harvest using mid-size commercially available storage and retail equipment.

Good results of Controlled Atmosphere

The results indicated that, even under adverse rainy season, CA (3 % O2 et 15 % CO2) delays rots development.

During retail simulation, “CA + refrigerated shelf-life” combination had the lowest losses. Additional techniques still need to be tested to lower fruit losses and meet the quality standards for commercialization.

Health promoting antioxidants (polyphenols, carotenoids and tocopherols) remained stable during storage. Only Vitamin C showed a significant decrease.

Loss of texture was noticed for Draper after 21 days in storage.

Other critical points influencing blueberry quality throughout the supply chain need to be fixed (genetics for epidermis elasticity and strength, machine-harvest, sorting and packing, post-harvest treatment, transport conditions).

A complete techno-economic assessment will be necessary to validate the benefits of the adoption of optimized pre- and post-harvest practices.

To this paper also contributed Absoger, specialist in all kind of Controlled Atmospheres, and Planasa, plant breeder.

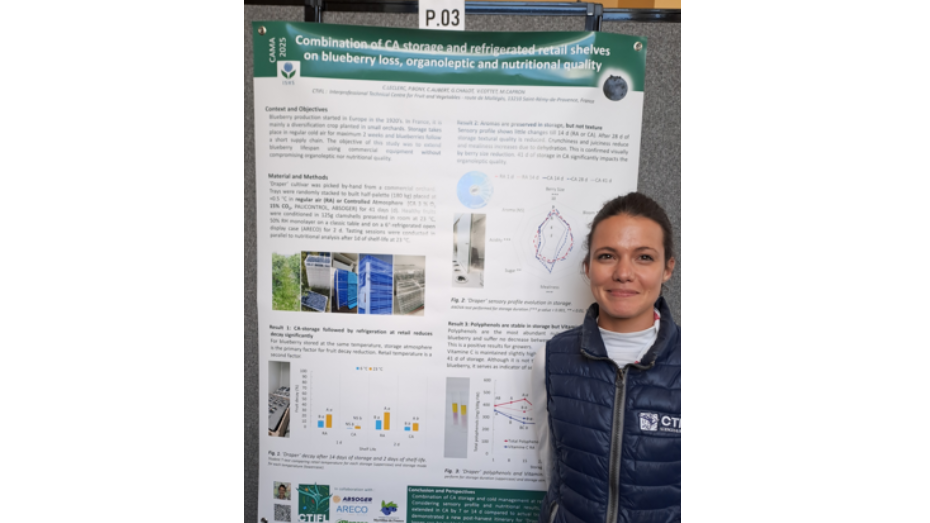

In the picture, Chloé Leclerc, at the poster session where this work was presented at CAMA 2025. The work was carried out by researchers from CTIFL Saint-Rémy-de-Provence, France.

Source

Combination of CA storage and refrigerated retail shelves on blueberry loss, organoleptic and nutritional quality

Chloé Leclerc, Philippe Bony, Christophe Aubert, Guillaume Chalot, Valentine Cottet, Myriam Capron & Melina Augereau

CAMA 2025, XIV International Conference on Controlled and Modified Atmosphere Research, held in Wenatchee, Washington, USA, May 18-22, 2025, https://cama2025.com