FAM STUMABO

Processing

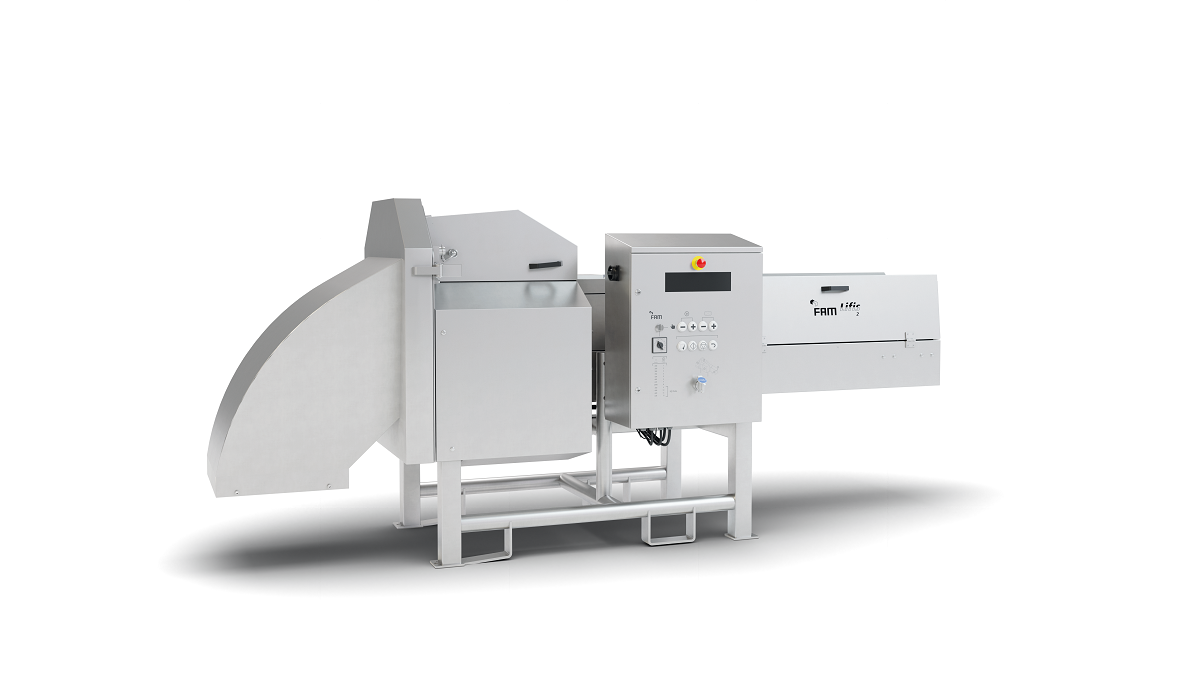

SureCut Unit, FAM STUMABO’s New Solution for 3-Dimensional Dicers

FAM STUMABO has developed the SureCut Unit, a system for 3-dimensional dicers that simplifies knife assembly and eliminates the need for on-line adjustments, improving efficiency, safety and consistency in potato and vegetable processing

In an interview with Fine Engineering, Philippe Van Parijs, Project Engineer at FAM STUMABO, shared insights into the company’s most recent development in precision cutting: the SureCut Unit. This solution was conceived to make the setup of 3-dimensional dicers faster and more reliable, reducing dependence on highly skilled labour and addressing one of the key challenges faced by today’s food processing plants.

FAM STUMABO belongs to the Hifferman Group and is recognised for its expertise in designing and assembling advanced mechanical cutting machines, along with the production of high-quality precision blades. With international reach and the spirit of a family-owned business, the company positions itself as a trusted partner for processors seeking accuracy, efficiency and consistency in high-volume food production.

What inspired the design of the SureCut Unit and how does it address today’s labour shortage challenges in food processing plants?

Philippe Van Parijs: The design of the SureCut Unit was primarily driven by the need for simplified setup of cutting tools on 3-dimensional cutting machines. All existing 3-dimensional cutting machines require the installation of individual cutting tools (slicing knife, slice guide, circular knife spindle), and fine-tuning on the machine is necessary for each cut size (setting the correct slice thickness and opening angle of the slice guide). Similar to centrifugal cutting machinery, we wanted to design cutting tools that can be installed as a pre-configured unit: one component that is easy to install and doesn’t require any extra fine-tuning at the machine.

Additionally, the timeframe for these operations is usually short, which pressures the operators to prepare the next production. Easier handling reduces the margin for error and requires lower technical skills. This provides an answer for food processing plants, which will need less qualified technical staff.

In terms of performance, what are the main differences and benefits introduced by the SureTec 240P model compared to previous versions?

P.V.P: Cutting tools can now be fully prepared offline while the machine is in operation. Once the machine is stopped, they can be installed within minutes for the next production run. At the machine, only installation handling (mounting two items: the SureCut Unit and the crosscut spindle) is required; no additional fine-tuning is needed at the machine. Production stops become shorter and more efficient.

Previous generations of 3-dimensional dicers required the assembly of several individual items on the machine, and after assembly, some additional fine-tuning was still needed to achieve the desired cutting quality.

Could you explain how the SureCut Unit improves operational safety and reduces user errors during line setup or adjustment?

P.V.P: With the SureCut Unit, the assembly of the cutting tools takes place off-line, away from the machine. This means that staff can work more comfortably and with less stress in an area separate from the machine.

All mechanical precision is contained within a single unit so that later, the assembled unit mounts effortlessly onto the machine.

We also offer a dedicated assembly station that holds the SureCut Unit while it is being prepared for a different cutting size.

The assembly station enables the technician to visually inspect each step of the assembly process and rotate the circular spindle to verify proper clearance with the other components.

The technology is described as “patent pending” – what makes it so unique from an engineering standpoint?

P.V.P: A 3-dimensional dicer performs three cutting actions: first, a slice of the desired thickness is made; second, that slice is cut into strips of the desired width using circular blades; and third, a crosscut spindle cuts the strips into dices of the desired height.

The first two actions are the most critical because they involve many individual mechanical parts that must fit precisely on the machine to guarantee good performance in the third action.

The SureCut Unit brings together all parts for actions 1 and 2 into a single unit, rather than as separate loose items.

How do these innovations contribute to reducing food waste and increasing sustainability in high-speed processing environments?

P.V.P: A ‘classical’ 3-dimensional dicer requires fine-tuning – such as changing the slice thickness, or adjusting the opening angle of the slice guide – while production is already in progress, resulting in badly cut product that gets rejected. The SureCut Unit adds repeatability for the cutting setup, eliminates the need for fine-tuning, and ensures product is immediately cut to the desired size.

What kind of feedback have you received so far from major processors, such as those in the French fries sector?

P.V.P: The SureCut Unit technology was introduced on the SureTec 240 machine, which was launched at the 2024 Anuga exhibition.

Immediately, we received a very positive response regarding the easy assembly process and how it brings repeatability in the production process.

Especially, the potato industry has become very interested, as production tonnage is very high and plants are always looking for better technology to increase efficiency.

A dedicated potato version (SureTec 240P) with features for that industry has been developed, and meanwhile, we have several projects ongoing at various potato processors.

Looking ahead, how do you see this technology evolving to meet future needs in precision cutting and automation?

P.V.P: Overall, we see that industrial plants are increasingly investing in automation that brings efficiency to their production process. The food industry is no exception, and new technology is gradually becoming part of it.

The introduction of the SureCut Unit could enable the use of techniques such as RFID to connect with MRP systems or even add various sensors to monitor the cutting process more effectively.

With these advances, FAM STUMABO continues to strengthen its position as a reference in precision cutting solutions, providing technologies that combine efficiency, safety and sustainability for the global food industry.

Source and cover image: Fine Engineering