Isolcell

Cooling and CA

Isolcell Drives Research with 16 Storage Rooms Installed at University of Bologna

Isolcell has installed 16 chambers with DCA-CF technology at the University of Bologna to improve the conservation of new fruit varieties. This initiative, part of the OCM021 project, aims to optimize post-harvest practices and strengthen the competitiveness of the fruit and vegetable sector in Emilia-Romagna.

Isolcell has successfully completed the installation of 16 new chambers with DCA-CF (HarvestWatch) technology, destined to research on the conservation capacity of new fruit species and varieties. This experimental infrastructure will allow the optimization of post-harvest practices, a key aspect to preserve the quality and profitability of fruit production in the Emilia-Romagna region.

The initiative is part of the project “Development of biotechnological innovations in the fruit postharvest sector - OCM021”, whose objective is to carry out trials and applied research in the harvest and postharvest phases. The ultimate goal is to obtain useful technical information to support regional fruit production, especially that organized through cooperatives and producer organizations.

The optimization of harvesting and post-harvest management is today a strategic priority for the fruit and vegetable sector, both in summer and autumn-winter productions, and represents a fundamental axis to ensure the competitiveness of the sector.

On the occasion of the installation of the new chambers, Isolcell organized a technical day for representatives of cooperatives in Emilia-Romagna. During the meeting, the objectives of the next campaign were defined and the research protocols and dissemination activities that will accompany the planned trials were agreed upon. The technical coordination is under the responsibility of the chief scientist Alessandro Bonora.

The meeting took place in the new multifunctional room of the agricultural company A.U.B., linked to the Alma Mater Studiorum - University of Bologna, in Cadriano. As part of the day, the attendees also visited the new experimental cells with controlled atmosphere of the experimental center of Cadriano, an infrastructure financed through the PNRR Agritech project.

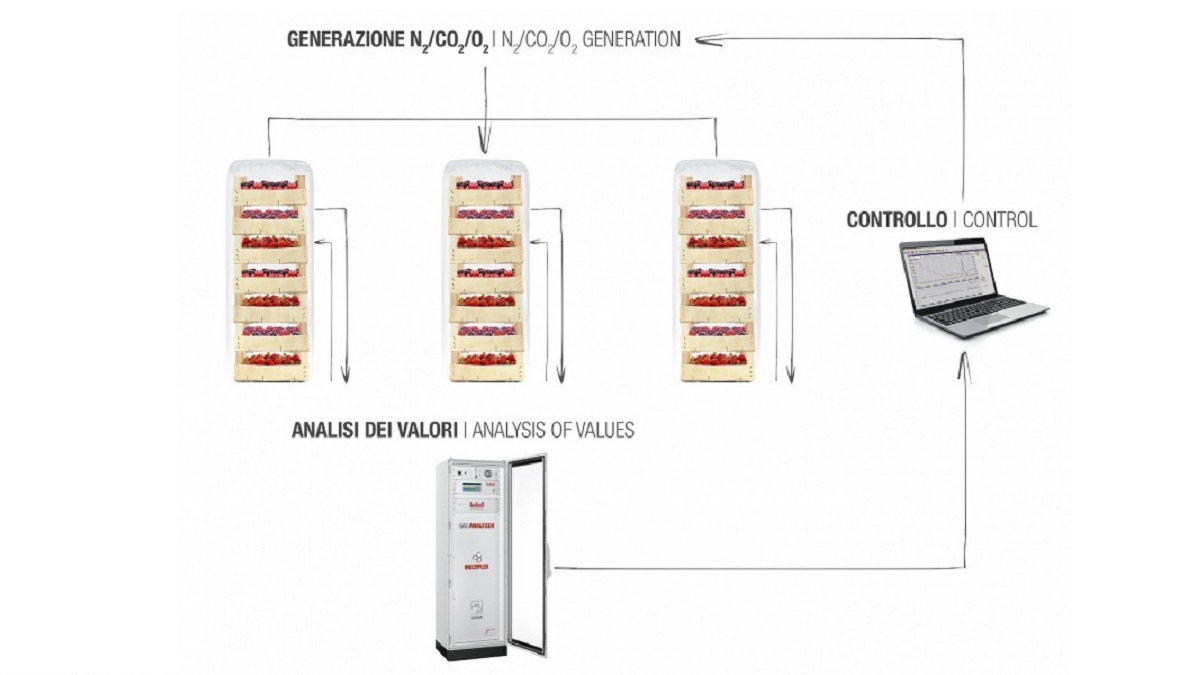

HarvestWatch® and the Isostore system: Advanced technology for safer, longer fruit storage

In 2003, ISOLCELL revolutionized fruit preservation by introducing dynamic controlled atmosphere (DCA) with HarvestWatch® fluorescence sensors. This unique technology allows oxygen to be reduced to a minimum without the risk of fermentation, which significantly improves storage quality.

The system adapts the atmosphere to the physiological state of the fruit by means of sensors that measure the fluorescence of chlorophyll in the skin. When oxygen falls below the safe limit (LOL), the signal increases, indicating the optimum level of control. This preserves the organoleptic properties of the freshly harvested product and avoids post-harvest chemical treatments such as anti-burn treatments.

The Isostore system offers multiple advantages in fruit preservation, such as control of blanching without the need for post-harvest chemical treatments, reduction of rotting and greater product uniformity. In addition, it maintains exceptional freshness and prolongs the storage period by reducing the respiration rate. Other benefits include improved organoleptic properties, preservation of the original color and the possibility of raising the storage temperature without compromising quality.

Cover page: Source