PND

Processing

Efficient Pomegranate Shelling for the Fresh-Cut Industry

Hygienic design and precise mechanical systems ensure high-quality aril extraction

PND Fruit Processing Machinery strengthens its position in the fresh-cut sector with advanced technology for pomegranate processing. Among its latest developments, the SM2 shelling machine stands out for its precision, hygiene and ability to maintain fruit integrity during aril extraction. This type of equipment responds to the growing market demand for healthy, ready-to-eat products that combine convenience and freshness.

Efficient and consistent shelling process

The SM2 shelling system, developed by PND, optimises the separation of arils from the peel through controlled mechanical action. Typically, the fruit is manually cut in half and placed into two processing heads. Inside, a lever mechanism intermittently taps the fruit, allowing the arils to detach cleanly without being crushed or torn.

This gentle approach preserves the colour, texture and juiciness of the arils, key parameters for the fresh-cut market. The extracted kernels fall directly onto a collection tray, which can be connected to a conveyor or integrated processing line. This flexibility allows the equipment to fit both semi-automatic setups and large-scale industrial operations.

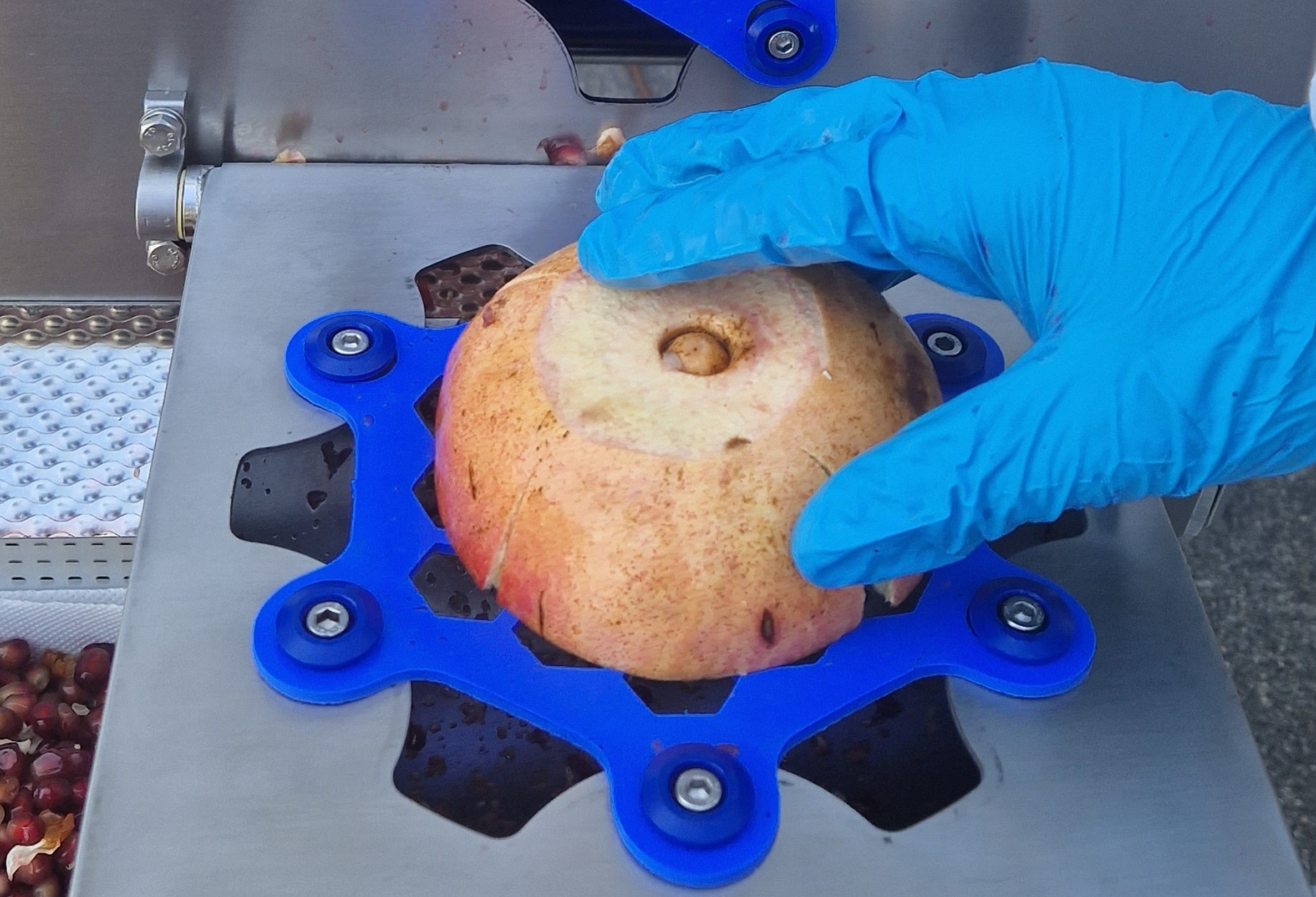

During the shelling process, arils detach cleanly from the peel

During the shelling process, arils detach cleanly from the peel

Hygienic design and easy maintenance

Constructed from stainless steel and food-grade materials, the SM2 combines durability with full compliance to international food safety standards. Its open-frame design ensures easy access for cleaning, reducing downtime and improving overall efficiency.

Key technical specifications include a production capacity of approximately six fruits per minute, compact dimensions (1100 × 815 × 1300 mm) and low energy consumption at 0.37 kW. Designed according to the European Machinery Directive 2006/42/EC, the SM2 guarantees high performance and operator safety while maintaining a minimal footprint on the production floor.

A versatile solution for pomegranate processors

Automation in pomegranate shelling not only reduces manual labour but also enhances yield consistency and hygiene, helping producers meet growing market demands. The combination of precise mechanical design and hygienic construction makes this type of machinery a valuable asset for companies working with fresh-cut, frozen or juice-processing lines.

By ensuring clean separation and gentle handling of the arils, processors can achieve higher-quality end products with extended shelf life and reduced waste, key advantages in a competitive global market.

Halved fruit positioned in the SM2 shelling unit

About PND

Founded in 2000, PND is one of the leading manufacturers of fruit processing machinery, continually investing in innovation and specialising in advanced systems for the minimally processed, canning, frozen and dehydrated industries. Its portfolio includes solutions for a wide range of fruits such as citrus, pineapple, watermelon, strawberry, kiwi, lemon, mango, apple, pear, peach, cherry tomato, butternut squash, pumpkin and pomegranate.

The company provides tailored assistance with multilingual technicians and on-site support in regions including Europe, the United States, Mexico, Chile, Peru, South Korea, Australia, South Africa, India and the United Arab Emirates. From design to commissioning, PND ensures the presence of trained experts during installation and offers rapid spare parts delivery within 24 hours of ordering, along with remote support. When issues cannot be resolved online or by phone, a specialist technician is dispatched within 48 hours, reinforcing the company’s commitment to efficiency and customer service.