T.R. Turoni

Measurements

Non-Destructive Tchnology for Quality Control in Berries

T.R. Turoni offers a non-destructive tool to assess ripeness in blueberries and cherries

In Italy, the berry harvesting season is underway, with blueberries and cherries taking center stage in several growing regions. During this period, accurately assessing ripeness is key to ensuring fruit reaches the market at its optimal stage in terms of both taste and texture.

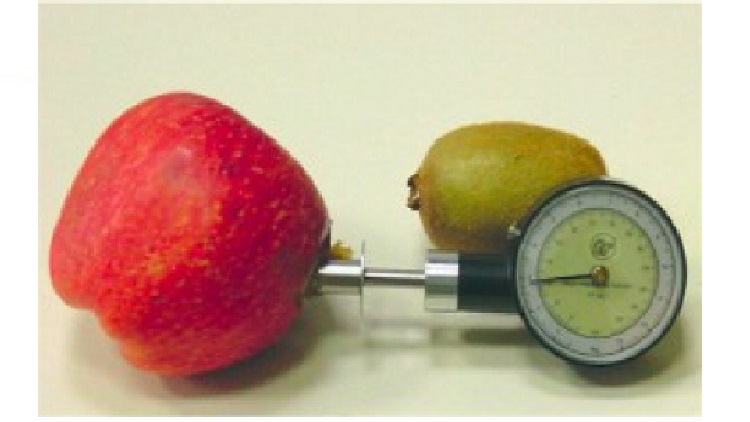

One of the most valued parameters for consumers is pulp firmness, especially in fruits sold at high prices per kilogram and expected to retain quality throughout distribution. To carry out this type of control without damaging the fruit, T.R. Turoni offers the digital durometer 53215, a precise and non-destructive tool that determines the degree of ripeness without piercing or altering the fruit.

Accurate measurement without damaging the fruit

Speaking to Fresh Plaza, Enrico Turoni, General Manager at T.R. Turoni, stated:

"Our proposal is a non-destructive method for measuring the pulp firmness of fruits such as cherries and blueberries. We have spent years investing in technology to support fresh produce companies in achieving optimal organoleptic quality."

T.R. Turoni’s 53215 digital durometer

The 53215 durometer simulates the pressure of a finger on the fruit surface and measures resistance, providing a value expressed in Shore degrees (10–90 Sh). Unlike traditional methods, the fruit is neither pierced nor altered, allowing it to be sold afterwards.

Enrico Turoni added:

"Since these products are sold at an attractive price per kilogram for the supply chain, they must reach the final market with the right level of ripeness to properly satisfy the consumer. For both fruits, pulp firmness is an important quality index. Most consumers appreciate a crisp texture at the time of consumption."

The device includes different tips adapted to the type of fruit. For berries such as blueberries, a spherical tip with a 2.38 mm diameter is used. The 53215 range is available in three versions:

- MODEL 53215BE: for very soft fruits such as blueberries, table grapes or strawberries

- MODEL 53215TP: for medium firmness fruits such as cherries or cherry tomatoes

- MODEL 53215TT: for firmer fruits such as avocados, cucumbers or citrus fruits

Advantages and usage of the 53215 durometer

The instrument stands out for its ease of use and for providing objective data, even on fruits that cannot be analyzed with destructive penetrometers. It also allows for continuous monitoring of ripeness in the same fruit over time, without causing any damage.

To measure, simply press the tip of the durometer against the meridional axis of the fruit and apply gradual pressure until the fruit touches the reference ring. For reliable results, it is recommended to sample fruits from different plants (in the field) or various boxes (in cold storage), and to take two measurements per fruit on opposite sides, approximately halfway up. The final value is the average of both readings and is expressed in the Shore scale, a standard reference for measuring hardness.

Enrico Turoni explained:

"Thanks to this instrument, we can quickly, accurately and non-invasively assess the pulp firmness of certain types of fruit, a key maturity index that directly affects the product’s shelf life. This makes it a top priority for monitoring, from harvest to point of sale."

Using this technology helps improve harvest planning, reduce sample waste and optimize berry storage and distribution, ensuring that fruit reaches the consumer with the expected texture and quality.

Source: Fresh Plaza