Brimapack

Conditioning

A key new vegetable harvester with an unique e-Drive system

BrimaPack hands over the key for a new vegetable harvester for Romain lettuce

Recently, the renowned company PDM from the United Kingdom proudly received its fourth BrimaPack harvester after successfully completing a factory acceptance test.

A harvester that raises the efficiency of the process to unprecedented heights

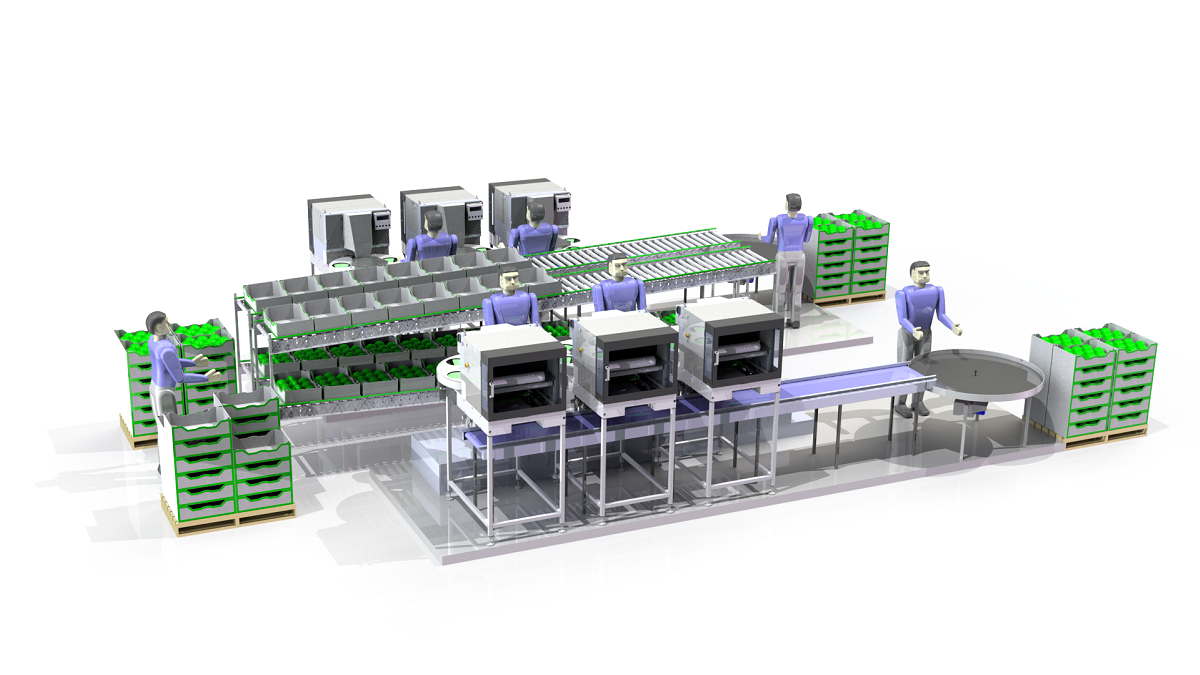

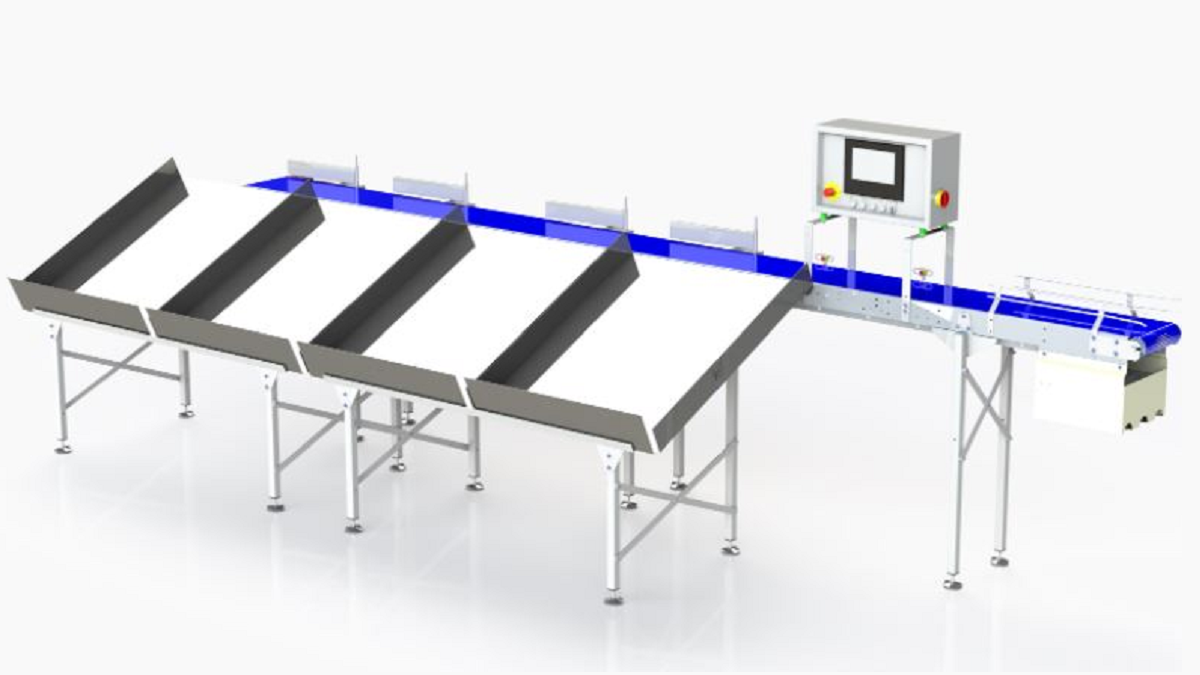

This state-of-the-art harvester with BrimaPack´s unique e-Drive system has been specifically designed for Romaine lettuce. It is equipped with a brand-new and unique "smart infeed" technology to enhance the efficiency of the harvesting process further.

This groundbreaking development serves as a response to the continuously rising labor costs and the scarcity of skilled workforce

BrimaPack Director Ron van de Pavert banded over the keys to PDM´s Managing Director - Farming Dermot Tobin.

The purchase of this cutting-edge harvester marks a significant milestone for PDM, solidifying its position as a leader in the agriculture industry. With their relentless pursuit of innovation and dedication to addressing industry challenges, PDM has once again revolutionized the farming landscape.

The implementation of the "smart infeed" system within the BrimaPack harvester guarantees optimal efficiency in the harvesting of Romaine lettuce. This technology uses advanced algorithms and intelligent sensors to accurately identify and process each head of lettuce with the utmost care and accuracy.

The result is a streamlined process that significantly reduces human error and minimizes the risk of damage to the delicate produce.

Construction processs

PDM, a leading technology company committed to sustainability

One of the major driving forces behind the development of this revolutionary technology is the urgent need to address rising labor shortages in the agricultural sector.

With the continuous advancement of technology, automation has become an indispensable solution to overcome these challenges. By automating the harvesting process with the BrimaPack harvester, PDM can reduce its reliance on manual labor, eliminating the need for additional labor and reducing the impact of rising labor costs.

Furthermore, the implementation of this state-of-the-art harvester demonstrates PDM´s unwavering commitment to sustainable farming practices. By optimizing the harvesting process and minimizing resource wastage, PDM contributes to a more eco-friendly agricultural landscape.

This not only aligns with current industry trends but also positions PDM as a responsible and environmentally conscious organization, striving to make a positive impact on global food production.

BrimaPack and PDM team

In conclusion, PDM´acquisition of the fourth BrimaPack harvester, specially designed for Romaine lettuce and equipped with the groundbreaking "smart infeed" technology, highlights the company´s dedication to innovation and its commitment to overcoming the challenges faced by the agricultural industry. With the ability to enhance efficiency, reduce labor costs, and support sustainable farming practices, this state-of-the-art harvester truly revolutionizes the way lettuce is harvested, securing PDM´position as a trailblazer in the field of agricultural technology.