Catalytic Generators

Cooling and CA

Greg Akins at Fruit Attraction 2025: Precise Ethylene Control for Consistent and Safe Ripening

In this interview, Greg Akins, President & CEO of Catalytic Generators, shares the keys behind their technologies’ success at Fruit Attraction 2025 and his vision for the future of fruit ripening

Following its participation in Fruit Attraction 2025, Catalytic Generators reaffirms its position as a global leader in the safe and controlled application of ethylene for fruit ripening. Its President & CEO, Greg Akins, highlights that this edition was “the best so far”, both in terms of attendance and the quality of leads generated. In this interview, Akins discusses the advantages of his system compared to other application methods, the company’s growing international presence, and the innovations shaping the future of ripening.

How did you experience this edition of Fruit Attraction, and what interest did you notice among your visitors?

It was the best edition thus far; attendance was incredible, and the quality of leads obtained exceptional. It seems everyone is looking for new and better ways to achieve quality, so we were a great place for them to stop and learn about our successful ethylene technologies.

What makes Catalytic Generators different from other ethylene ripening systems?

-

We bring peace of mind to ripeners. Unlike other ethylene suppliers, we don’t sell a hundred gases. We sell one: ethylene. That means we never run out, and neither do our customers. The worst thing that can happen to a company that ripens bananas is to run out of ethylene. Without it, they cannot operate their business. And we know ripening; with years of experience in banana ripening, we understand our clients’ needs when it comes to ethylene, or other parts of ripening.

-

We emphasize “set-and-forget” dependability: reliability, simplicity and safety.

-

Also, purity; compressed ethylene systems must severely dilute their ethylene for safety reasons. Our system produces high-purity ethylene and cannot reach explosive levels. This makes for better ethylene at better costs.

Your equipment places strong emphasis on safety and ease of use. How do customers perceive this in their day-to-day operations?

See third point above for safety. We do not have to dilute our ethylene output to prevent explosive levels. We safely generate continuous, small amounts of high-purity ethylene so that proper levels are quickly achieved and maintained.

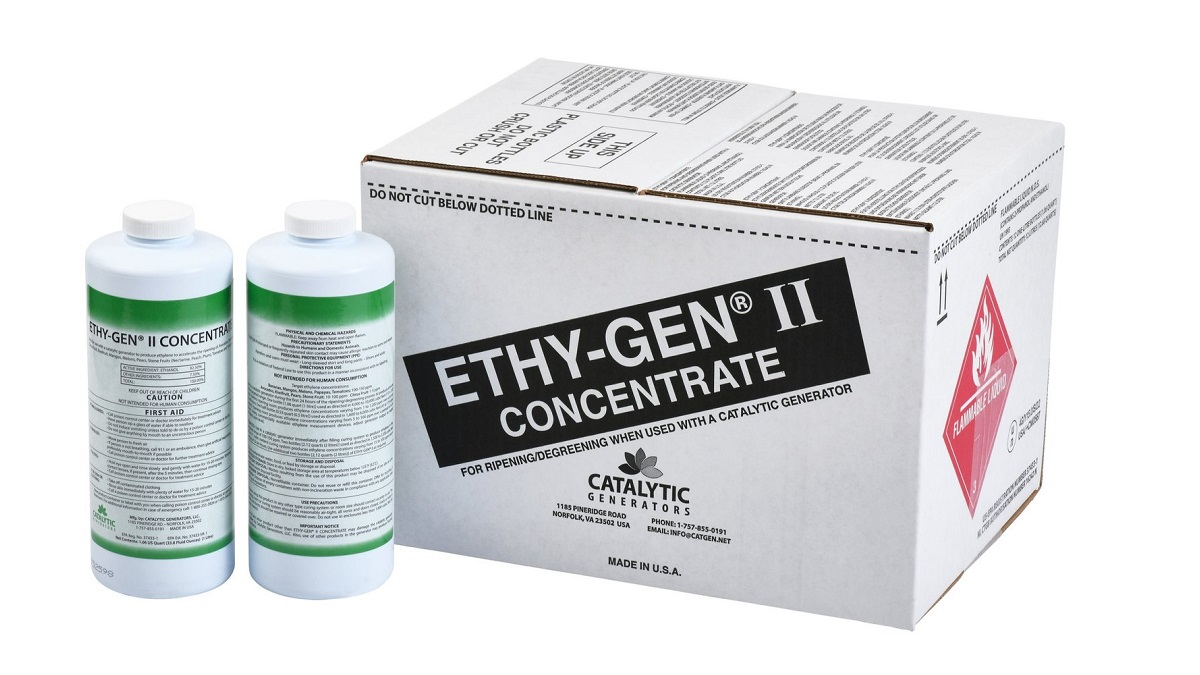

Ease of use: just pour in a liter of Ethy-Gen® II, and power on the machine. Ethylene production starts in minutes and continues for 24 hours. The next day, the user can check the generator’s reservoir and see that the liter was converted to ethylene, and know that the process was successful.

Adjustability: clients are quite happy with the fact that you can manually control our generator’s ethylene production with a one-time ethylene measurement upon the first use of the generator; after making initial adjustments, the ethylene production is repeatable and proper ethylene levels are easily maintained.

Ethy-Gen® II in use

Ethy-Gen® II in use

Avocados are gaining prominence in Europe. What does your system offer to those working with ready-to-eat fruit?

While ripening of avocados has been around for 50 years, the process with ethylene application for them went mainstream about 25 years ago. This has tremendously helped with ready-to-eat avocado sales, giving customers a dependable ripeness. As with bananas, our generators are successfully used worldwide for avocado ripening.

What differences do you see between ripening processes in the U.S. and Europe, and how do you adapt your technology to each market?

There’s not much difference in terms of ethylene application, so there has been no real need to adapt our technology. It’s all about ease and assurance of application. After starting in the US, we’ve been in the UK, Canada and Middle East for over 40 years, leading those markets in ethylene for fruit ripening. About 15 years ago we started exporting to Australia and help many fresh produce companies and retailers there. Brazil is now a large market for us too, introducing our systems there about 10 years ago. We do business on all continents; now with our growing list of European authorisations for Ethy-Gen® II Concentrate, we are steadily adding customers.

Looking ahead, where is Catalytic Generators’ innovation in ripening headed over the coming years?

Remote management of generators is one thing. We have staff dedicated to evolving technologies, and if there’s something that we can do to improve the application, but keep it simple, affordable and effective, we’ll do it!

About Catalytic Generators

With over 50 years of experience, Catalytic Generators is a family-owned company dedicated exclusively to ethylene application systems and known for making ethylene easy, safe, and cost-effective. Based in Norfolk, Virginia, USA, it operates across the globe, supplying fresh produce companies, grocery distribution centers, and growers with the tools to ripen avocados, bananas, tomatoes, and more. It helps customers simplify operations and achieve consistent, predictable results with its high-purity ethylene solutions backed by professional support, local distribution, and customized services. Catalytic Generators’ commitment to quality and customer partnership ensures a reliable and timely supply of ethylene for customers worldwide.

News of Catalytic Generators