FAM STUMABO

Processing

FAM STUMABO showcases its most compact and versatile solutions for vegetable processing

We spoke with Santiago Díaz, Director of FAM STUMABO Ibérica, following Fruit Attraction, about the company’s latest innovations and outlook in the fresh-cut market.

Fruit Attraction once again served as a meeting point for leading companies in the fruit and vegetable sector. Among them was FAM STUMABO, which showcased increasingly compact, precise, and versatile cutting solutions. We spoke with Santiago Díaz, Director of FAM STUMABO Ibérica, to learn how the company continues to drive efficiency, quality, and innovation in vegetable processing. His insights reflect the company’s commitment to providing technologies tailored to the evolving demands of the industry and a market increasingly focused on sustainability and added value.

How did you perceive Fruit Attraction this year, and what type of customers showed the most interest in your stand?

The overall perception of the FAM STUMABO booth and products was very positive. The focus of our presentation was on our smallest and most compact models, specifically designed to meet the needs of small and medium-sized companies that process vegetables.

Visitors appreciated the machine design, efficiency, and compact footprint, which make them ideal for businesses with limited space but demanding processing requirements.

Overall, the tradeshow successfully reinforced our brand as a reliable partner for efficient vegetable cutting solutions.

Which solutions did you highlight in this edition, and how do they address the current demands of the fresh-cut (IV range) segment?

At this year’s Fruit Attraction, we carefully selected solutions from our portfolio that directly respond to the latest demands of the fresh-cut (IV range) market, ensuring processors gain efficiency, precision, and maximum product value.

We highlighted three flagship machines:

- Volantis™ – our advanced V-belt slicer, engineered to deliver perfect transverse slices of long and oblong produce. With its high-speed, innovative cutting method, Volantis ensures uniform, smooth-surfaced slices while minimizing product waste. It’s the go-to solution for processors aiming for consistent, high-quality results at medium to high volumes.

- Dorphy – a compact powerhouse for dicing, strip cutting, and slicing. Designed for flexibility and precision, Dorphy not only boosts productivity but also reduces waste, helping extend product shelf life and optimize profitability. It’s the ideal fit for processors looking to achieve premium results with maximum efficiency.

- Centris™ 315 – our compact yet highly accurate slicer and shredder. Delivering uniform cuts at high output, Centris 315 combines performance with cost-effectiveness, enabling processors to streamline operations while ensuring quality and consistency.

Beyond the live demonstrations, visitors experienced our full machine portfolio through engaging 3D animations and videos. And of course, the FAM STUMABO expert sales team was on hand to guide discussions and match the right solutions to each processor’s unique needs.

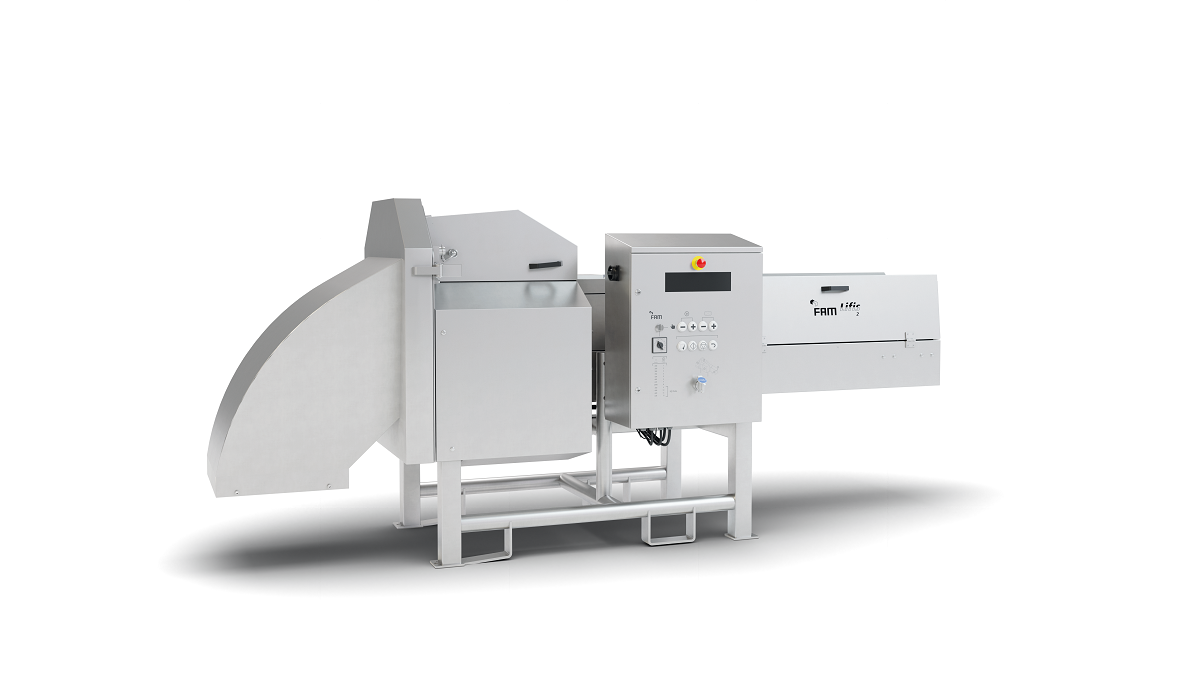

Centris™ 315 slicer, designed to deliver uniform cuts with high throughput and precision

Centris™ 315 slicer, designed to deliver uniform cuts with high throughput and precision

How do your machines ensure consistent cuts in delicate products such as leafy greens or herbs, and what real impact does this have on shelf life?

Consistency and shelf life are critical when processing delicate products like leafy greens and herbs — and that’s exactly where FAM STUMABO machines excel. For this edition, we deliberately chose to highlight three standout solutions from our portfolio:

- Volantis™ – a high-performance V-belt slicer designed for medium to high volumes. With its high knife speed and innovative cutting method, Volantis guarantees smooth, uniform slices with minimal breakage. The result? Premium presentation, reduced waste, and longer-lasting freshness for fresh-cut products.

- Yuran™ Capcitec – purpose-built for peppers and leafy vegetables, this versatile machine ensures uniform distribution and continuous production, delivering consistent dicing and strip-cutting even for the most delicate products.

- Flexis (Optitec) – our ultra-flexible flat-belt slicer, built for low to medium capacities, combines sophistication with precision. Its advanced cutting technique minimizes juice loss, ensuring perfect slices and significantly extending product shelf life.

Beyond the machines themselves, the secret to consistency lies in the blades. At FAM STUMABO, we design and manufacture premium precision blades in-house — including patented innovations from our Food R&D team. These groundbreaking blade technologies ensure processors get exactly what they need to handle herbs, leafy greens, and fruits with care, efficiency, and reliability.

Yuran™ Capcitec, a high-capacity belt slicer for leafy vegetables and peppers

Yuran™ Capcitec, a high-capacity belt slicer for leafy vegetables and peppers

What differences do you see between the demands of processors in Spain and Portugal compared to other European markets?

In general terms, there is no significant difference between the demands of processors in Spain and Portugal and those in other European markets. In fact, several European visitors who stopped by our stand recognized that the machines we exhibited perfectly fit their operational requirements, reinforcing the universality of our solutions for the vegetable processing sector.

What lines of technological innovation is FAM STUMABO working on for 2026?

Looking ahead to 2026, FAM STUMABO is preparing to raise the bar in cutting technology with several exciting new machines set to launch next year. While we can’t reveal specifics just yet, our ongoing commitment is clear: to deliver innovations that empower processors with greater efficiency, precision, and flexibility.

At the same time, we continue to evolve our existing range of fruit and vegetable cutters. By working hand-in-hand with our customers, we refine and adapt cutting tools to create tailored solutions that directly address their challenges and unlock new opportunities.

Our global presence is a key driver of innovation. Partnering with processors around the world exposes us to an incredible variety of products – including exotic fruits and vegetables – pushing us to engineer solutions that meet the most demanding and diverse cutting requirements.