Grup Giró

Packaging

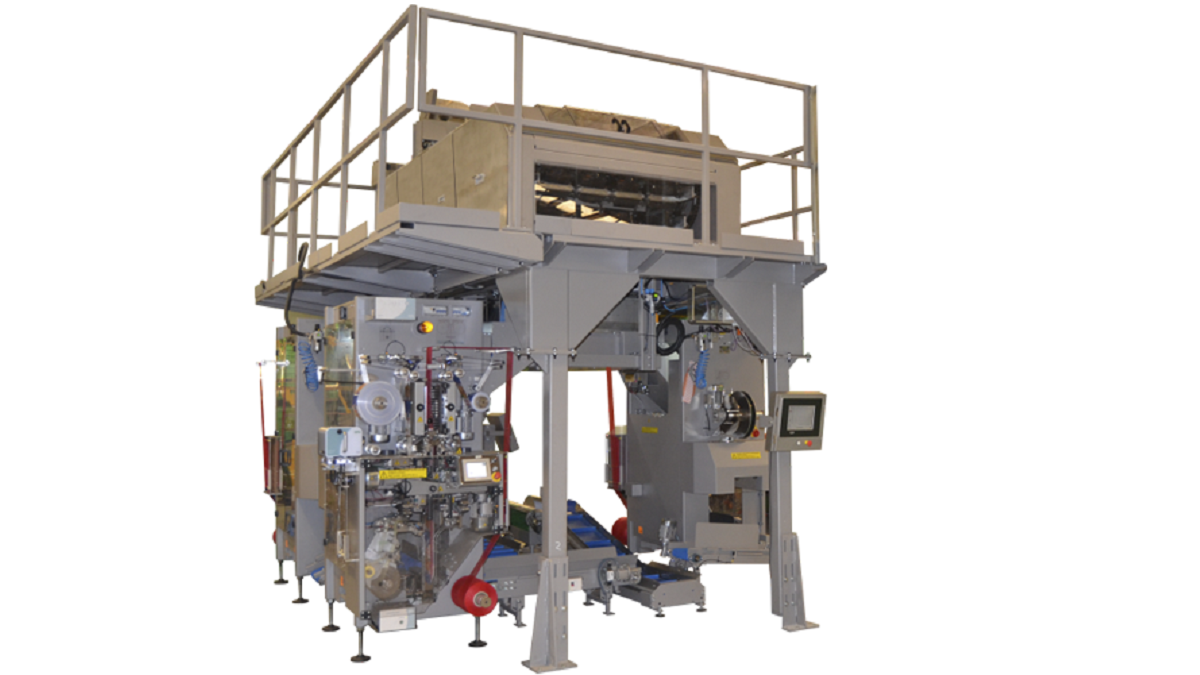

CA-10, the World?s first automatic clipping machine using netting reel, a clipped net machine that (almost) doesn't stop

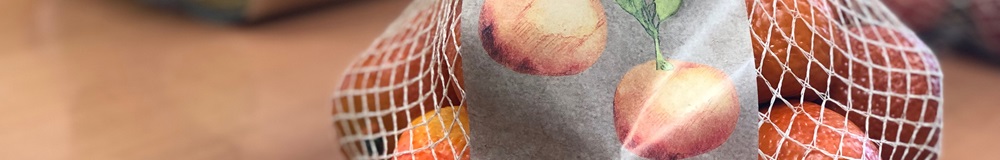

The CA-10, by GIRO, is the the Worlds first automatic clipping machine using netting reel. It revolutionizes the world of traditional net clipped packing because, from now on, it is not necessary to remove the feeding tube to load the net. There are several advantages with this innovation: greater autonomy of operation, use of net reels (which saves storage volume) and, most important, much less operators dedication because it doesnt need filling net tubes or make tube replacement. Shortly: a great savings in operating cost. Net clipping machines (or clippers, as also they are known) have been provided with one or two tubes of net allowing to feed the fruit through them and also they load the net to be used. Depending on the net width, tube diameter and other factors, this net tube is loaded with 100 to 200 meters of tubular net that offer a range of operation around 10-20 minutes. Lets show a practical case: a packaging machine that performs 35 bags per minute, using 40 cm of tubular net per bag and the net tube loaded with 150 meters of net, will need to refill the tube with net every 10.7 min. Although the machine has a double net tube, and, when a net tube ends automatically starts using the second filled tube, will be necessary to remove and refill the empty tube. Of course behind this filling process there is an operator who needs some time to do the refill. However, the Giró CA-10 incorporates a patented auto-fill double tube from net reels. These two net reels, which can contain a total amount of 3,000 or 3,500 meters of net, are simultaneously filling when necessary, their respective tubes. So that operator task to provide the net should not be performed every 150 meters but every 3,000 or 3,500 meters. Is that important? Definitely. The cost of any manufactured product is a combination of the raw material costs, operating costs (or labor) and all expenses attributable to production. The labor costs are directly related to the time taken to perform the task. And the CA-10 saves a lot of operating cost. A traditional automatic double tube clipping machine, as the Giró CA-9 requires a 23.6% of the operator workday to refill consumables. With the automatic net loading system, the CA-10 requires only 7.5% of the operator workday make the change for all supplies (net, wineglass labels and clipping wire). The figures are indisputable: the new machine represents a significant cost saving labor. Look at it another way. While an automatic double tube clipping machine requires 6,6 minutes of operator time every 1.000 bags, the new CA-10 requires only 2,3 minutes per thousand bags. CA-10 saves 68% of the operators time to refill consumables. More information

Are you interested in this product?

Fill out the form and we will contact you as soon as possible