Grup Giró

Packaging

GIRCLIP: Revolutionizing Packaging with Giró's 100% Monomaterial Plastic Clip Innovation!

Giró's GirClip: Eco-friendly plastic clip for sustainable packaging, eliminating metal, promoting recyclability, and supporting the circular economy

Giró has been working for years on projects and initiatives aligned with its strong commitment to sustainability. The company is dedicated to eco-design, aiming to reduce the environmental impact throughout the life cycle of its products, from design to disposal, while promoting the circular economy. To achieve this, Giró allocates significant resources to Research and Development (R&D), ensuring the continuous development of products that are increasingly environmentally friendly.

As a result of this commitment to innovation, we present the new product created by Giró: GirClip.

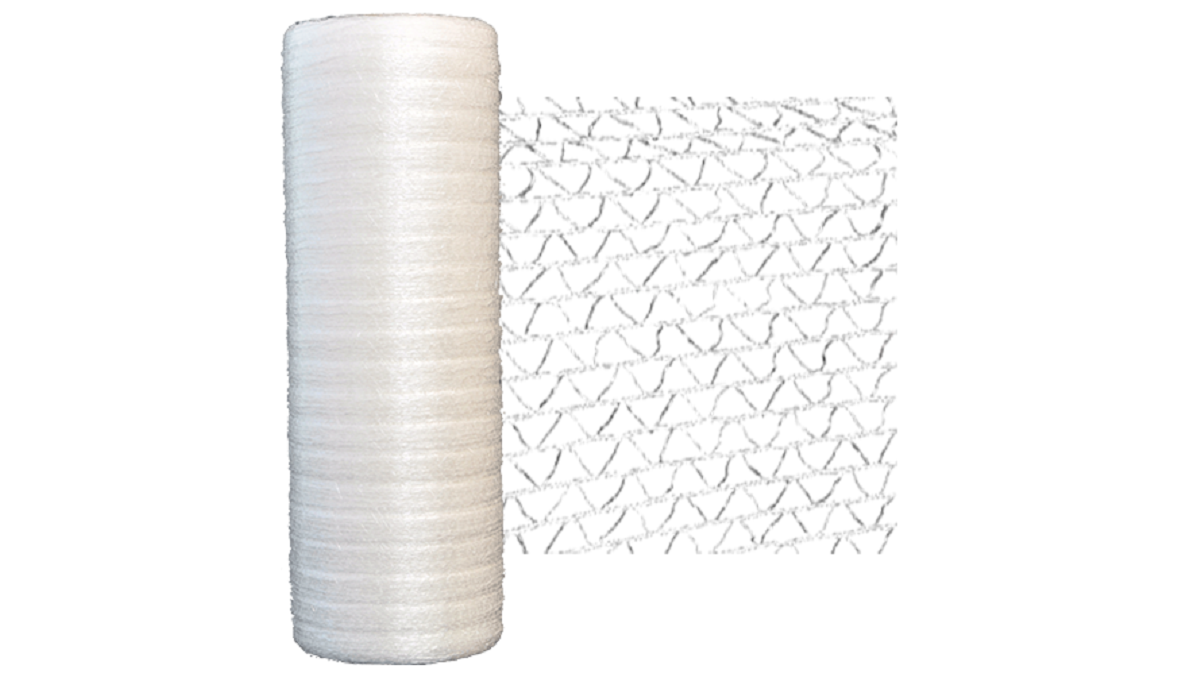

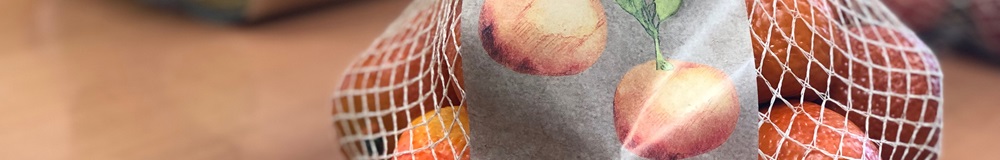

GirClip is a plastic clip that will allow us to replace the current metal clip and obtain a clipped bag made of 100% monomaterial plastic, facilitating recyclability and promoting a model based on the circular economy. Until now, clipped bags of fruit and vegetables had two metal clips that were used to close the bags and to incorporate the label with the product information. With GirClip (100% plastic), the same functionalities offered by the metal clip are maintained, but achieving a package made of 100% plastic. In the initial stage, the maximum recommended weight of clipped bags with GirClip is 1,5 kg. Still, the expected improvement in the production of the clips makes us foresee an increase in resistance and therefore an increase in the weight of the contents of the package soon. The GirClip plastic clip design is exclusive to Giró and is currently patent pending in Spain.

Sergi Pentinat, Grup Giró Business Manager, at Fruit Logistica 2024

Sergi Pentinat, Grup Giró Business Manager, at Fruit Logistica 2024

GirClip benefits

On the environment:

- Elimination of a foreign element in the pack, such as the metal clip, which is replaced by a 100% plastic clip.

- As it is a monoproduct packaging, there is no need to separate the plastic materials from the non-plastic ones, making it easier for the consumer when disposing of the waste.

- Reduction of the risk of contamination of the recycling stream.

- Support circular economy.

For the packer:

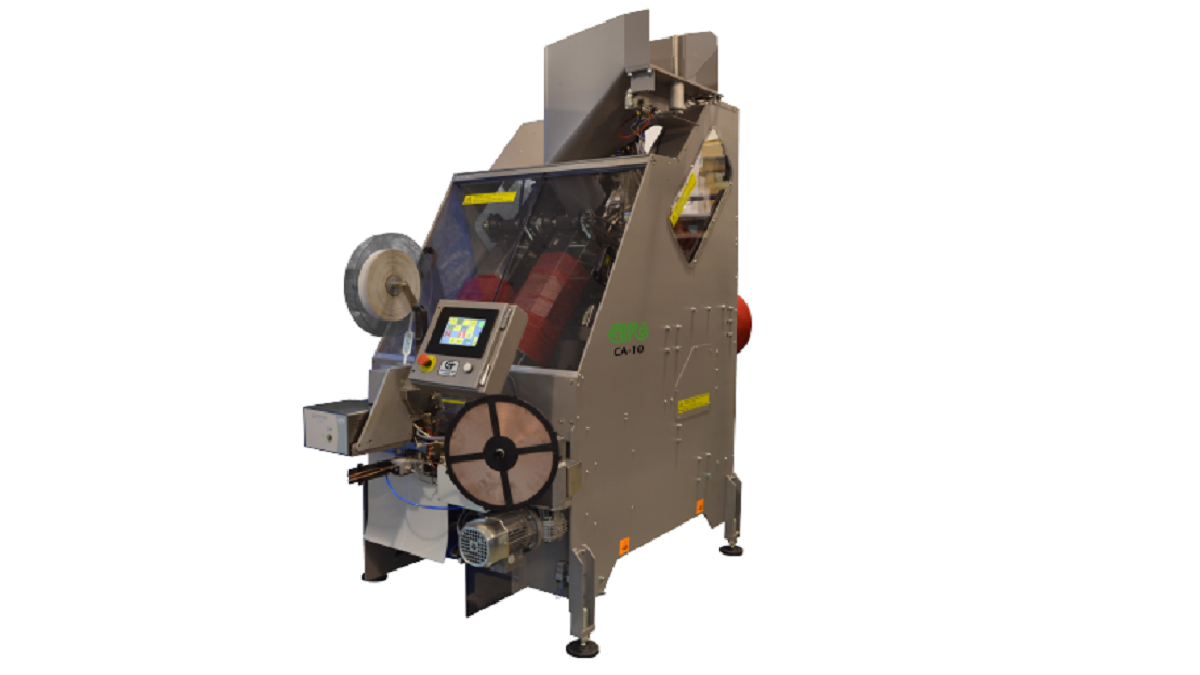

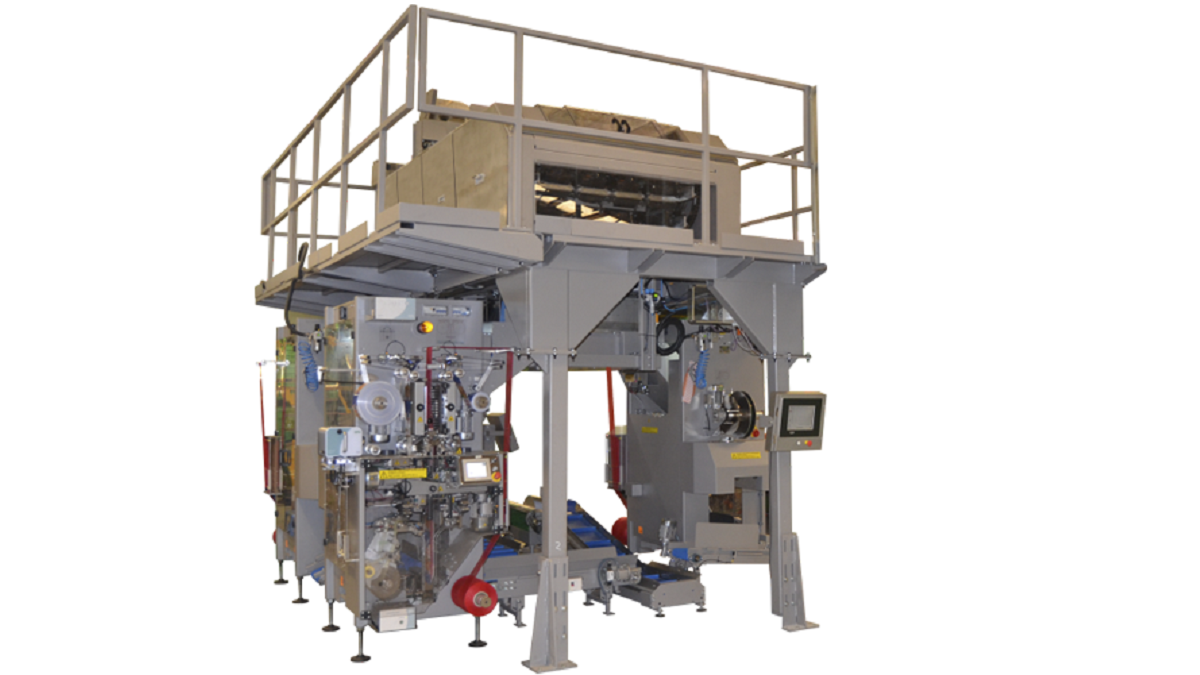

- It does not affect the operation of the packing plant since the output of our CA-9S/CA-10 GirClip machine is about 35 bags/minute (1 kg bags), similar to that of the existing clippers with metallic clips.

- Ease of replacing old clipping machines with conventional clipping heads (metal clip) with new clipping machines with GirClip heads, since they occupy the same footprint.

- Possibility to upgrade existing clipping machines by replacing only the clipping head (when the existing Giró clipper is a CA-9S or CA-10 version sold after 2010)

A new clipping system that is easy to implement

Comparison of the technical specifications of a conventional CA-9S machine vs CA-9S GirClip: