Grup Giró

Packaging

Giró consumables: Integrated traceability in all the process

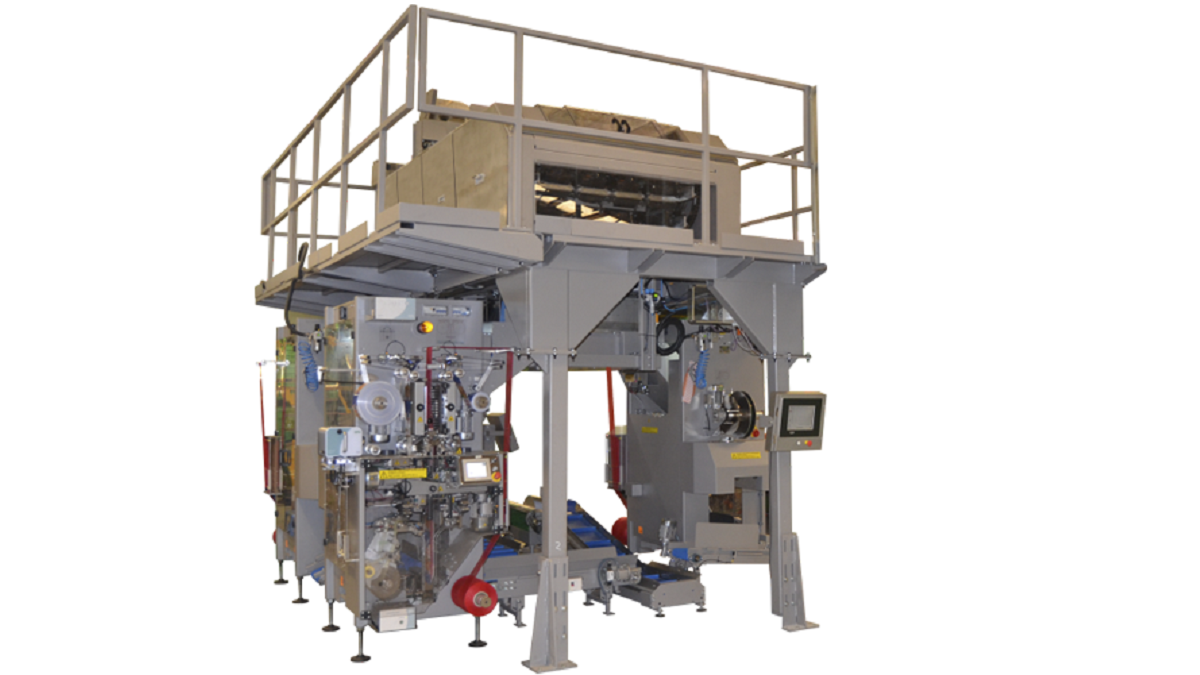

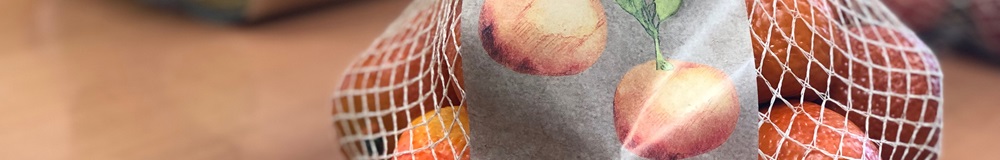

GIRO currently offers information and control system of consumables traceability than any other company in the industry can offer. A bidirectional integrated system, from raw material to the fruit bag and from the bag to the raw material, allows Giró to know which batch of raw material, which operators were involved and which productive resources have been used in the consumables that made a package that can be found at the point of sale or in the hands of the consumer. This is only possible thanks to strict reporting processes and internal control and also being the first company in the world offering the SCS (Smart Consumables System) intelligent packaging system that performs an automated reading of consumables involved in the packaging. One concern of all food operating companies is the quality control throughout the production flow and distribution chain.Traceability is a key component in the management of quality control and it should also include all the information of the packaging process and materials used therein.Once again Giró shows its ability to innovate and bring solutions to the market. Giró has been developing a traceability system integrated than any other company in the industry can currently offer. To achieve this goal it was necessary to carry out two major projects: the management of internal traceability during the production and logistics process that takes place in Giró and, secondly, to develop a method that allows packers manage adequately and automated traceability of consumables used for each package. Traceability in our production processGiró makes exhaustive management of internal traceability. Any raw material received in any of Giro factories in the world is immediately labeled, revised by quality laboratory and registered in the ERP-SAP computer system. All subsequent steps that are made in the production process, both in making the nets as in the production of printed goods, are also recorded and coded in the system. In each checkpoint of the manufacturing process we use labels with barcodes and readers to record the information in the system, both in regard to semi-finished and operators involved in each task as well as industrial machinery used in every process. At the end, the finished product also conveniently identified, has been registered in the management system with all its history. The process does not end here. The product is supplied to our customers and it is also imperative that the information also travel with the product, not only including those traceability data on the label but also in the documents accompanying the shipment like delivery notes or invoices. Besides all this sophisticated system Giró incorporates the finished product with RFID tags that can be read by our packaging machines equipped with SCS (Smart Consumables System). Traceability in the packing plantWhen the Giró SCS consumable reaches the packing plant, the GirBagger machines or CA-10 can read automatically (without further operator intervention), consumables: both net as Girfilm and labels. Simply loading the reels on the machine, it takes a reading of the consumable, verifies that it is adequate to start production as it has been previously reported and records the traceability code (unique for each reel) in the GirControl Plus database. Simultaneously, during the development of packaging batch, each bag can be labeled by incorporating a traceability code that generates the labeling machine, identifying packaging machine and the date and time of the bagging. This information is also stored in the GirControl Plus database. The package is delivered to the consumer with a tracking code that allows the packer to know what packaging machine and when it was made. With that information it can be obtained from the GirControl Plus database all the consumables traceability codes used specifically in that bag. This information allows Giró to find all the information related to production: raw materials batch used, production dates, industrial machinery and operators involved in that shift. More informationGiró Magazine February 2015

Are you interested in this product?

Fill out the form and we will contact you as soon as possible