Ilerfred

Cooling and CA

Forced-Air Pre-Cooling: A Key Technique in Postharvest Management

Forced-air pre-cooling is one of the most important techniques in the postharvest management of fruits and vegetables, as it allows the rapid removal of thermal load accumulated during harvesting.

This immediate temperature reduction is essential to prevent undesirable physiological processes, such as intensified respiratory activity, excessive ethylene production, or accelerated senescence. In this way, the fresh product maintains its quality and, therefore, its commercial value for a longer period.

The system forces all the cold air to pass through the bins or pallets containing the fruits or vegetables. Unlike static refrigeration, forced air penetrates more quickly into the load, achieving fast and uniform heat extraction. This makes it an especially effective tool for water-sensitive products, where cooling uniformity is crucial.

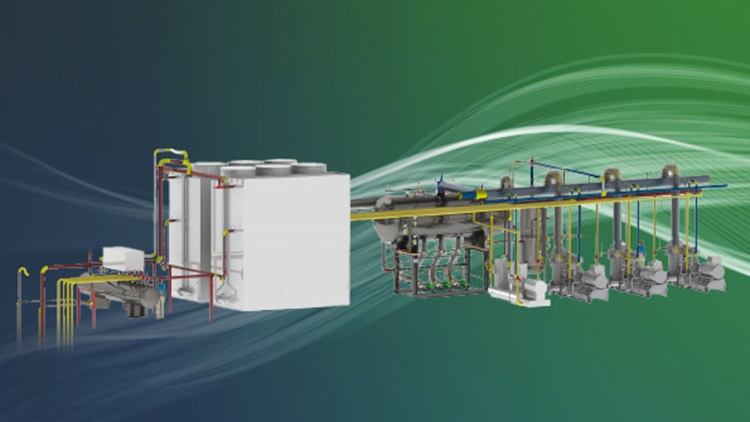

Operating diagram of rapid pre-cooling

Among its technical advantages are the rapid reduction of temperature, decreased handling and thermal stress damage, and a lower incidence of postharvest diseases. In addition, it is a system adaptable to different crops such as blueberries, grapes, cherries, stone fruits, tomatoes, bananas, and leafy vegetables.

In terms of types, there are fixed tunnels (installed in high-capacity cold rooms), mobile units (portable and more economical, designed for medium-scale or multi-location operations), and dynamic or continuous systems (automated, offering maximum efficiency and speed, ideal for large-scale industrial flows).

The strategic implementation of forced-air pre-cooling ensures the preservation of quality parameters, reduces product rejection, and increases the competitiveness of the agri-food supply chain. The choice of the most suitable system should be based on a technical analysis that considers the type of product, processing volumes, and installed capacity.

About ILERFRED

Industrial Leridana del Frío S.L., trading under the name ILERFRED, is a company dedicated since 1986 to the design, execution, and maintenance of refrigeration and controlled atmosphere installations.

The ILERFRED Group, headquartered in Lleida, has regional representatives providing technical service in Barcelona, La Almunia de Doña Godina, Calahorra, Madrid, and Málaga. The group includes Industrial Cold Generation S.L., located in Rubí, and SIC24, which operates its own alarm receiving center, offering installation and management services for security systems, fire protection, CCTV, and access control.

At ILERFRED, we have over 4,000 m² of facilities, including workshops, material warehouses, a programming and control laboratory, a compressor repair room, a paint booth, welding stations, offices, and a garage. We have a team of more than 100 professionals and a fleet of around 60 fully equipped vehicles.