Ilerfred

Cooling and CA

Humidity Control in Controlled Atmosphere: Key to Preserving Apples and Pears

A study presented by Ilerfred at CAMA 2025 shows that precise humidity regulation under controlled atmosphere conditions reduces weight loss and improves the postharvest quality of apples and pears.

Efficient storage of pome fruits such as apples and pears is essential for reducing economic losses and ensuring high postharvest quality. At the CAMA 2025 (Controlled Atmosphere and Modified Atmosphere Conference) held at Washington State University (Wenatchee, USA), Ilerfred presented a study on the impact of controlled atmosphere (CA) conditions on stored fruit. The presentation was delivered by Laia Torregrosa, Director of the R&D&I Department at Ilerfred.

The Importance of Controlled Atmosphere in Cold Storage

Controlled atmosphere (CA) technology plays a vital role in maintaining fruit quality during long-term storage. Under CA conditions, factors such as relative humidity (RH), oxygen, and carbon dioxide levels are precisely regulated to minimize weight loss, fruit shrinkage, and settling inside the storage bin.

Study Results on ‘Golden’ Apples and ‘Conference’ Pears

During her presentation at CAMA 2025, L. Torregrosa shared the results of experiments conducted with a specialized device that continuously measures:

- Diameter shrinkage of the fruit

- Settling within the storage bin (palot)

- Mass loss during storage

Key findings included:

- Fruit shrinkage is inversely proportional to RH levels.

- Smaller apples showed greater shrinkage (up to 2.5%) than larger ones (approx. 1%).

- Increasing RH from 90% to 95% significantly reduced shrinkage.

- There is an almost linear relationship between fruit mass loss and settling within the bin.

These results confirm that precise humidity control is essential to preserve postharvest fruit quality and reduce losses.

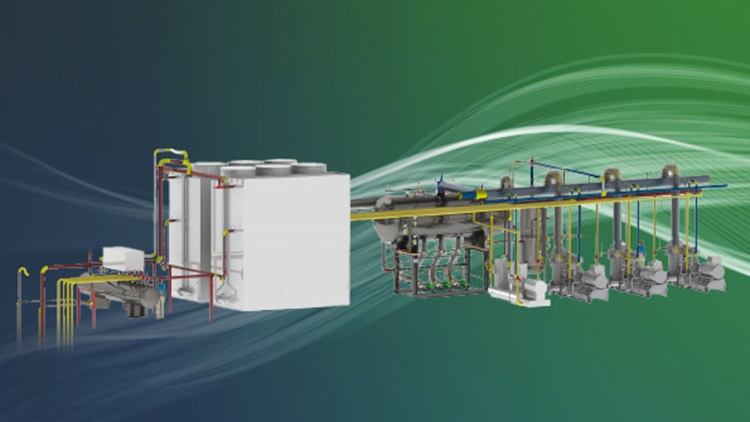

Innovation in Service of the Fresh Produce Industry

Ilerfred reaffirms its commitment to technological innovation and energy efficiency in industrial refrigeration systems. Its participation in CAMA 2025 further strengthens the company’s position as a benchmark provider of refrigeration solutions for the agri-food sector.

The study also highlighted that settling measurement using ultrasonic sensors is a simple and effective technique for monitoring fruit weight loss in commercial cold rooms—allowing for better control of humidification systems. Changes in air RH directly affected both fruit mass loss and settling rates.

Conclusion

Optimizing controlled atmosphere conditions not only enhances the storage quality of pome fruits but also helps reduce economic and environmental losses. Ilerfred continues to advance the development of technologies that bring added value across the entire agri-food supply chain.