Ilerfred

Cooling and CA

Why Is Pre-Cooling Key to Preserving Stone Fruit?

Pre-cooling plays a vital role in preserving stone fruit by rapidly lowering its temperature after harvest. This process slows down the physiological and biochemical changes that lead to quality loss, minimizes water loss, and limits microbial activity—ultimately extending freshness and shelf life

Once harvested, fruit undergoes—or accelerates—a series of natural processes that directly affect its quality. The single most effective way to delay these changes is to reduce the fruit’s temperature quickly. Known as pre-cooling, this step is essential for maintaining freshness, reducing dehydration, and limiting microbial growth, thereby extending the product’s shelf life.

What Is Pre-Cooling?

Pre-cooling refers to the rapid reduction of fruit temperature immediately after harvest, preventing warm produce from entering cold storage. As explained by Dr. Laia Torregrosa, Head of R&D at ILERFRED, during her presentation at PostharvestTALKS Fraga:

"Bringing warm produce into the cold room increases moisture loss and accelerates quality degradation."

Common pre-cooling methods include hydrocooling, forced-air cooling, vacuum cooling, and ice cooling. For stone fruits—such as peaches, nectarines, and cherries—hydrocooling and forced-air cooling are the most widely used and effective techniques.

Hydrocooling: Speed and Firmness

Hydrocooling is particularly valued for its ability to rapidly reduce fruit temperature, helping to maintain firmness and reduce moisture loss. Additionally, it allows for the integration of postharvest treatments directly into the cooling water, offering extra benefits such as the prevention of physiological disorders.

However, hydrocooling also presents some challenges: it requires proper water treatment to prevent contamination, consumes slightly more energy than air cooling, and demands packaging materials compatible with water immersion.

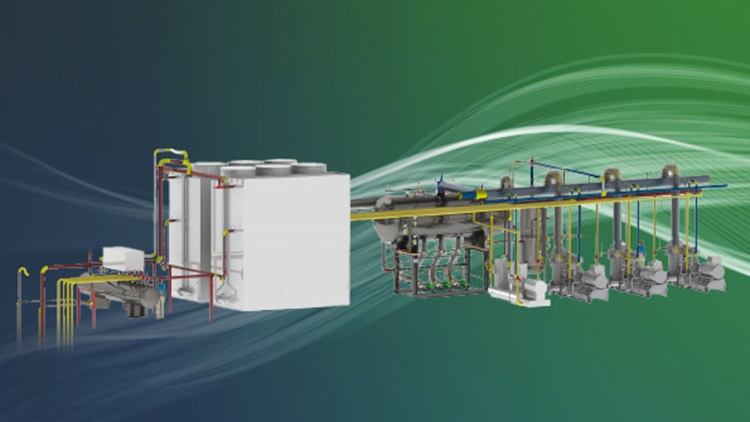

Technical Features of Hydrocoolers

Typical hydrocoolers are around 1.8 meters tall, allowing for the direct entry of palletized produce. Built with double stainless steel sheeting, they feature drip-breaker trays that slow the water flow and protect the fruit. Hydrocoolers are available in static and dynamic models. Dynamic models are equipped with a conveyor belt to regulate exposure time based on product flow. A recent improvement includes automated doors, facilitating loading and unloading by forklift.

Proven Impact

In partnership with the IRTA Postharvest Technical Service, ILERFRED has evaluated the effects of pre-cooling on internal fruit defects (such as browning, reddening, and mealiness) and quality attributes. For peaches, for example, hydrocooling has been shown to significantly reduce the incidence of early-stage, non-visible infections, improve firmness, and enhance the release of volatile compounds, improving sensory perception.

Forced-Air Cooling: Versatility and Cleanliness

As an alternative to hydrocooling, forced-air cooling offers a clean, efficient, and highly versatile solution. While it cools more slowly, its simplicity, low risk of contamination, and minimal water use make it attractive for many fruit packing facilities.

These systems can be installed in fixed or mobile tunnels, or adapted to standard cold rooms using tarps and suction fans. This flexibility allows for easy integration into existing facilities.

Dynamic hydrocoolers with conveyor belts typically measure around 5 meters in length and allow for adjustable exposure times (5 to 20 minutes), which can be scaled by combining multiple tunnels to meet production volumes.

Conclusion

Pre-cooling is a critical step in ensuring the postharvest quality of stone fruits. Choosing the right system—water or air—depends on various technical and logistical factors. When properly applied, both methods offer effective solutions to preserve freshness, reduce losses, and maintain product excellence from field to consumer.