Maf Roda

Conditioning

From manual sorting to computer vision, post-harvesting enters a new era

On Thursday, September 11, 2025, the 4th Citrus Post-Harvesting Conference was held in Valencia, organized by IVIA, AgroBank, and Poscosecha.com

The event served as an annual forum for exchange between research, commercialization, industry, and distribution, where the previous season was analyzed, and perspectives and new developments for the upcoming season were discussed.

During the conference, key technical and commercial issues for the citrus sector were addressed, as well as intelligent sorting technologies, new carbon and water footprint certifications, challenges in storage, innovation in plant-based coatings, as well as varietal novelties and the launch of digital platforms like Naranjasyfrutas.com.

Jorge Domingo, a computer vision programming technician at MAF Roda, presented the presentation "Smart: Artificial intelligence at the service of fruit sorting." He explained how new technologies are making it possible to optimize defect detection and improve post-harvest efficiency.

G7 SMART: Vision with AI, Software at the service of external quality sorting

Traditionally, citrus sorting was done manually, a slow and subjective process. Today, with the rapid emergence and incorporation of AI, sorting has become fast, objective, and precise, which translates into higher final product quality and fewer losses.

MAF Roda's G7 SMART can detect both defined and diffuse defects, even when the fruit has several problems at the same time. Thanks to machine learning, the system recognizes spots, rot, or complex defects after being trained with examples, continuously incorporating new types of damage.

Domingo, explained:

"Artificial intelligence needs a large number of samples to learn effectively. A fruit and vegetable packing house is the ideal place for this because tons of fruit are handled there, which gives us the quantity of examples the system requires."

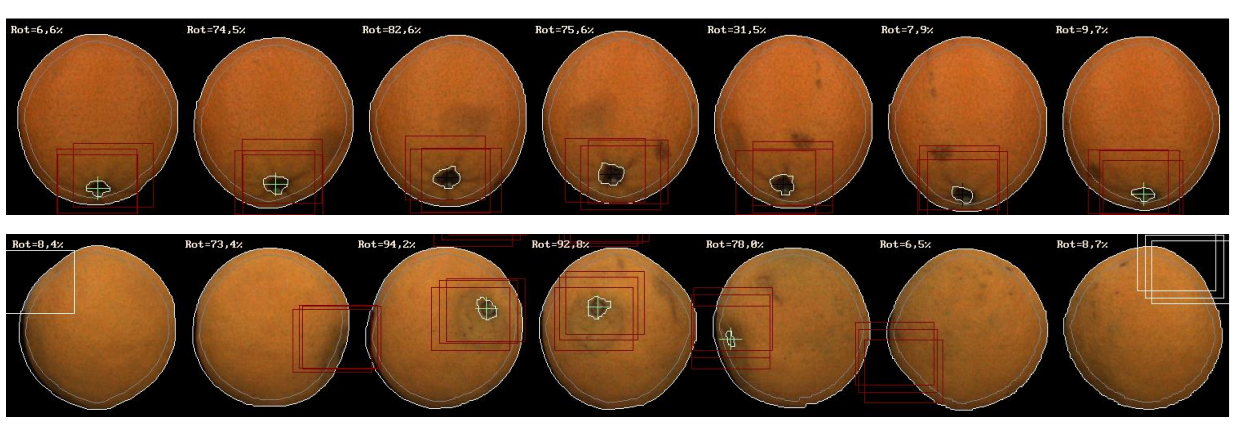

G7 Smart's AI Recognition Software View

G7 Smart's AI Recognition Software View

Among the main benefits of using artificial intelligence in post-harvesting, MAF Roda highlighted:

-

Greater autonomy in personalizing results.

-

Rapid incorporation of new defects.

-

Simplification in parameter configuration.

-

Increased process efficiency.

-

Continuous and autonomous system improvement.

With this innovation, MAF Roda reinforces its commitment to the automation and digitalization of the sector, offering solutions that provide efficiency, precision, and sustainability to the citrus value chain.