Marvil Engineering

Cooling and CA

Marvil’s DCA Technology: Smart, Sustainable Storage for Superior Fruit Quality

Marvil’s DCA technology offers a cutting-edge, chemical-free solution for long-term fruit storage by precisely controlling ultra-low oxygen levels to prevent disorders like superficial scald, extend shelf life, and preserve fruit quality naturally and efficiently

In recent years, fruit storage technology has evolved rapidly, with techniques increasingly relying on ultra-low concentrations of oxygen and carbon dioxide to better preserve quality during long-term storage. One such method, ULO (Ultra Low Oxygen), gained widespread adoption in the late 20th century for its effectiveness in extending shelf life. However, it has since been overtaken by a more advanced and responsive approach: DCA (Dynamic Controlled Atmosphere).

Introduced in the early 2000s and developed from the ILOS (Initial Low Oxygen Stress) concept, DCA was specifically engineered to address superficial scald—a physiological disorder that affects certain apple and pear cultivars after extended storage. This disorder can significantly diminish the fruit’s appearance and marketability. Unlike traditional treatments, DCA provides a chemical-free, sustainable solution that protects fruit naturally by controlling atmospheric composition with precision.

How DCA Works

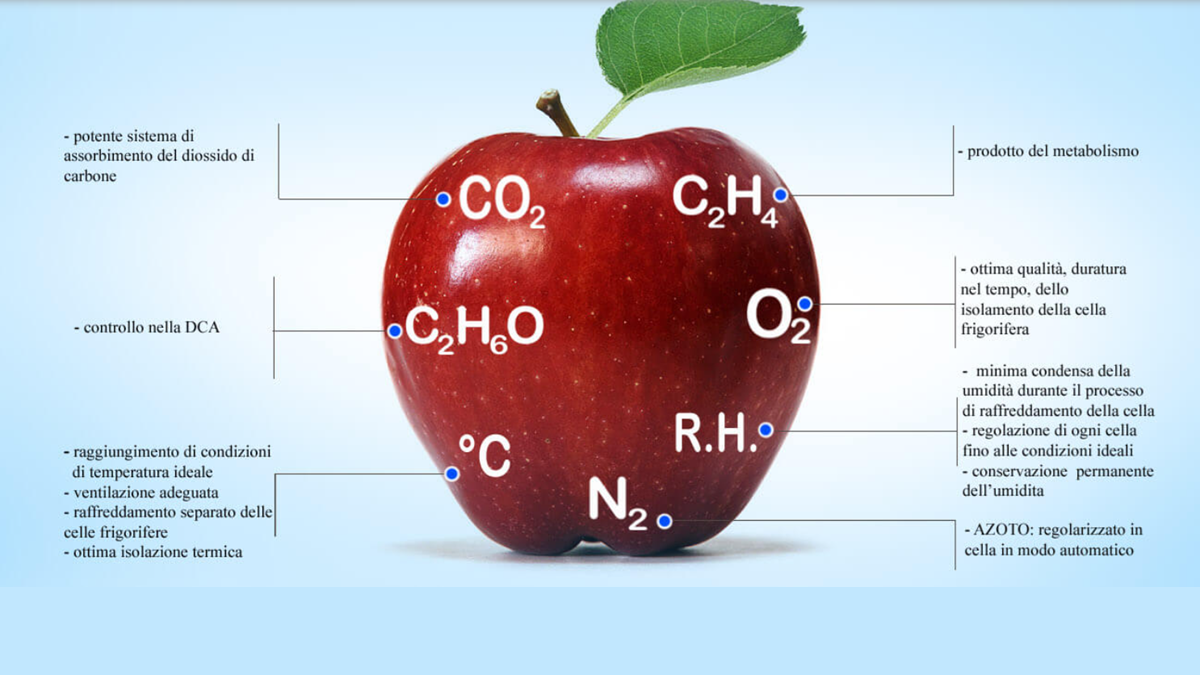

At the core of DCA is the strategic reduction of oxygen to near-anoxic levels. While these extreme conditions might appear risky—since prolonged exposure can lead to cellular damage or even fruit death—the process is precisely monitored. These low oxygen levels trigger a controlled stress response in the fruit, which leads to a significant reduction in metabolic activity and the activation of natural self-defense mechanisms.

This temporary suppression of metabolism not only prevents the onset of storage disorders like superficial scald but also extends shelf life. Once the oxygen is restored to normal levels, the fruit resumes its natural ripening process, maintaining flavor, texture, and commercial quality.

Marvil’s Integrated DCA Technology

With decades of expertise in postharvest systems, Marvil has optimized DCA implementation to ensure maximum safety and performance. Their approach has led to:

-

Complete elimination of superficial scald in many cases,

-

Significantly extended storage life, and

-

Enhanced product quality post-storage.

To deliver these results with ease and precision, Marvil integrates fully or partially automated systems, which include:

-

Nitrogen generators for safe oxygen displacement,

-

CO₂ absorbers to stabilize the internal atmosphere, and

-

Ethylene converters to delay ripening.

These components are managed through advanced computerized control systems, ensuring real-time data analysis and atmospheric regulation. The entire process is chemical-free, relying solely on the manipulation of air composition—making it an environmentally responsible, clean-label solution.

Advanced Monitoring: Intelligent Atmosphere Management

Precise control of oxygen and carbon dioxide levels is essential for the success of both ULO and DCA systems. Marvil sets the standard with its proprietary MEGAS instrumentation, a robust solution tailored specifically for ultra-low oxygen environments.

MEGAS enables reliable, user-friendly analysis and regulation of gas levels in storage facilities, ensuring long-term stability and safety. For added versatility, Marvil also offers HELPY, a portable analysis unit that brings convenience and mobility to atmosphere management.

Housed in a sleek protective case and equipped with all essential accessories, HELPY features:

-

A lightweight, compact design

-

An intuitive interface for inputting custom analysis parameters

-

Clear, color-coded graphical results for rapid decision-making

Whether for routine monitoring or spot-checking conditions across storage rooms, HELPY is a practical and powerful tool for postharvest professionals.

Conclusion

Together, these technologies form a smart, efficient, and natural storage system that maximizes postharvest performance while preserving fruit integrity. By combining biological insight with engineering precision, Marvil's DCA technology offers a future-proof solution for the fruit storage industry—without compromising quality, sustainability, or ease of use.