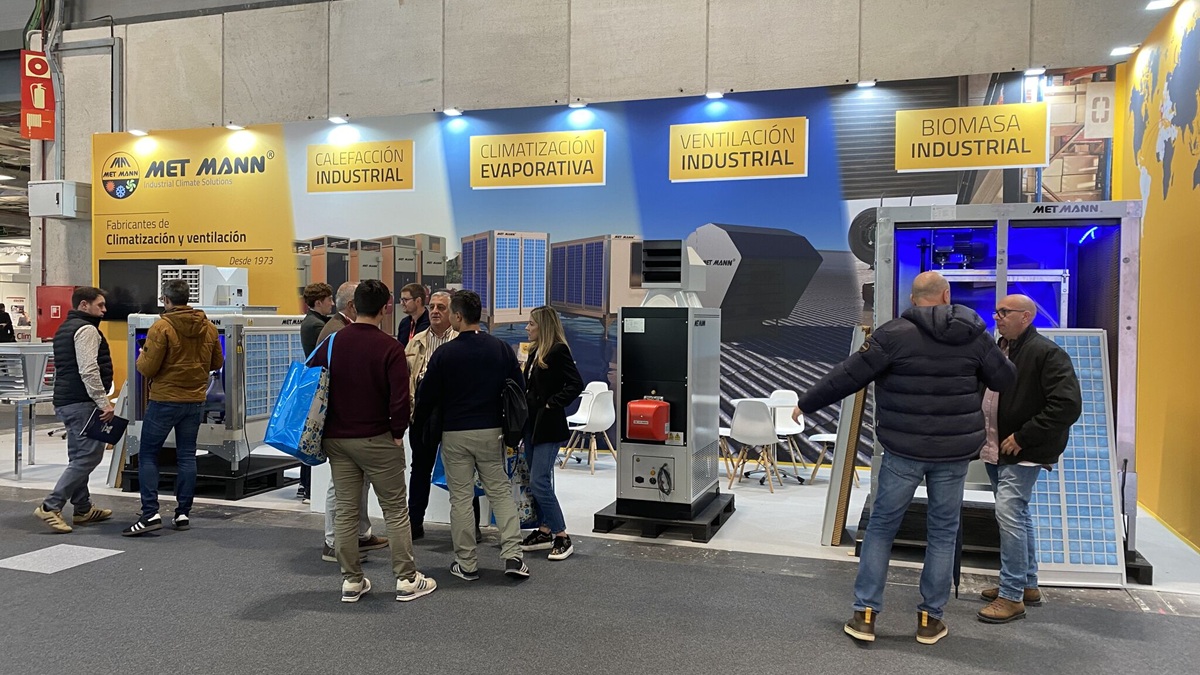

Met Mann

Cooling and CA

Solution for More Homogeneous Air Distribution in Fruit and Vegetable Storage Facilities

MET MANN’s CI-300 High-Induction Nozzles Optimize Air Diffusion in Industrial and Postharvest Environments

Achieving proper air distribution is essential to maintain stable environmental conditions in fruit and vegetable storage facilities, packing houses and industrial plants. Ensuring that airflow reaches critical zones, while avoiding stratification and dead spots, requires devices capable of combining throw distance, directional control and efficiency.

In this context, MET MANN's CI-300 high-induction nozzles offer an effective solution for improving thermal uniformity and ventilation in large-volume spaces. Their polyamide design, with a fixed 45° tilt and 360° rotation, allows the airflow to be adapted to the real needs of each installation. They can reach distances of up to 35 metres and operate with variable airflows between 50 and 1,750 m³/h.

Real-world application confirms the performance of CI-300 nozzles

In a recent industrial installation, several CI-300 units were incorporated for their ability to significantly enhance air circulation in large areas. According to MET MANN, the installation demonstrates how high-induction nozzles make it possible to direct airflow precisely, optimizing the performance of the heating, ventilation or air-conditioning systems into which they are integrated.

The result has been a reduction in temperature differences inside the building, improved ambient comfort and increased system efficiency. This type of upgrade is especially relevant in agri-food environments, where climate stability directly contributes to preserving fresh produce and ensuring proper postharvest operations.

MET MANN solutions for air treatment and climate control

MET MANN offers a broad range of equipment designed for air control, movement and conditioning in industrial and agri-food sectors. Its main solutions include:

- Toberas y difusores de alta inducción para climatización y enfriamiento evaporativo

- Hot air generators for drying processes and heating

- Industrial evaporative coolers, ideal for supplying fresh air with low energy consumption

- Industrial fans and extractors for improved air renewal

- Dehumidification systems, essential for facilities requiring precise humidity control

With more than five decades of experience, MET MANN has become a reference provider in the design of robust, efficient solutions tailored to the needs of the horticultural and food industry.