TOMRA Food

Conditioning

LUCAi™ revolutionizes apple sorting with contextual Deep Learning

LUCAi™ for apples, TOMRA Food's innovative sorting solution, uses Deep Learning to analyze each fruit holistically, improving the detection of critical defects such as cracks and perforations in the stalk area

Traditional machine learning-based classification systems evaluate only small sections of the fruit, analyzing a few pixels at a time and making decisions based on limited local information. This approach can be unreliable when interpreting complex textures, especially in critical areas such as the cavity and stalk, leading to false positives and commercial losses.

Tomra's LUCAi™ makes a difference. As an advanced Deep Learning model, it replicates the functioning of the human brain's visual cortex, capable of understanding an image as a whole. Instead of making isolated interpretations, LUCAi™ analyzes each apple holistically and contextually, evaluating all its features at the same time.

Thanks to this holistic view, it accurately recognizes natural structures such as the peduncle or peduncular cavity, preventing their misclassification as defects. The technology has been trained with thousands of high-quality images collected during more than 20 commercial campaigns, allowing it to accurately predict the severity of each anomaly.

Advanced integration with Spectrim: massive analysis and full operational control

LUCAi™ integrates seamlessly with the Spectrim vision platform, processing up to 40,000 images per minute with exceptional accuracy. This massive analysis capability allows each block to be classified based on advanced, customizable criteria, including:

- Defect category. Accurate identification of the type of imperfection, differentiating actual defects from natural features such as peduncle or peduncle cavity.

- Confidence level. Accurate estimation of the degree of certainty in each grading decision, facilitating adjustments according to commercial standards.

- Degree of severity. Quantitative scale (0-100) that measures the importance of each defect, allowing fine control over the final quality of the product.

Thanks to this integration, LUCAi™ offers a number of key operational advantages:

- Superior defect detection. Eliminates more than 95% of critical imperfections in the stem area, including cracks and splits that are difficult to detect with traditional systems.

- Intuitive interface and full control. Its graphical interface is accessible to operators at all levels, ensuring effective model management and continuous performance optimization.

- Consistent and uninterrupted performance. Reduces sorting errors (false positives and negatives), avoiding unnecessary losses and improving overall packaging efficiency.

- Operational consistency between campaigns. LUCAi™ maintains a high level of performance regardless of variety, lot, season or operator, ensuring uniform quality and improved profitability in every cycle.

About TOMRA Food

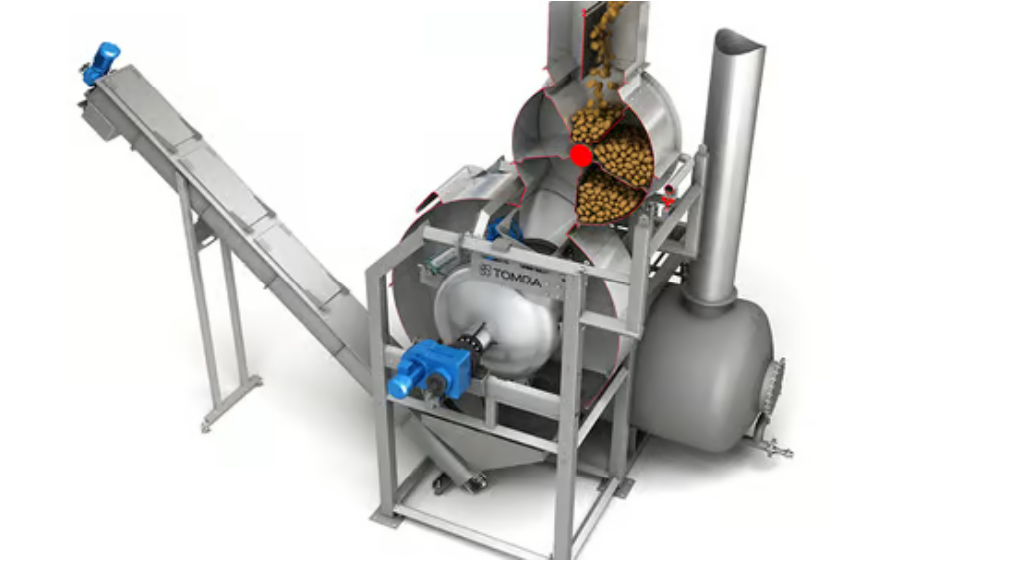

TOMRA Food designs and manufactures sensor-based sorting machines and integrated post-harvest solutions transforming global food production to maximize food safety and minimize food loss, by making sure Every Resource Counts TM .

The company has more than 13,800 units installed at food growers, packers and processors around the world for Confectionery, Fruit, Dried fruit, Grains and Seeds, Potatoes, Proteins, Nuts, and Vegetables.

These solutions include advanced grading, sorting, peeling and analytical technology to help businesses improve returns, gain operational efficiencies, and ensure a safe food supply.

TOMRA Food operates centers of excellence, regional offices and manufacturing locations within the United States, Europe, South America, Asia, Africa and Australasia.

Follow TOMRA Food on Facebook @TOMRA.Food, X @TOMRAFood, Instagram @TOMRAFood, LinkedIn at TOMRA Food and YouTube at TOMRA Food.

TOMRA Food is a division of TOMRA Group. TOMRA was founded in 1972 that began with the design, manufacturing and sale of reverse vending machines (RVMs) for automated collection of used beverage containers.

Today, TOMRA is leading the resource revolution to transform how the planet’s resources are obtained, used and reused to enable a world without waste. The company’s other business divisions are TOMRA Recycling and TOMRA Collection.

TOMRA has approximately 105,000 installations in over 100 markets worldwide and had total revenues of about 12 billion NOK in 2022. The Group employs 5,000 globally and is publicly listed on the Oslo Stock Exchange. The company headquarters are in Asker, Norway.

For further information about TOMRA, visit www.tomra.com.

Source

Cover photo: Tomra