.jpg)

TOMRA Food

Conditioning

Pacific Coast Producers Enhances Canned Fruit Operations with New TOMRA Sorting Technology

Pacific Coast Producers has expanded its use of TOMRA sorting technology, including the TOMRA 5A, 5B, and Sentinel II, to enhance quality, efficiency, and throughput in its canned fruit operations across its California facilities

Pacific Coast Producers (PCP), a long-time partner of TOMRA Food, has recently made a significant investment in TOMRA sorting technology to enhance its canned fruit operations. As a loyal customer for over three decades, PCP now operates a total of 51 TOMRA sorters across their facilities in Woodland, Dalles, Lodi, and Oroville, California. Among the latest additions to their sorting lineup are the TOMRA 5A and TOMRA 5B, key machines that support not only throughput but also quality and labor efficiency in the company's operations.

In a recent feature of their Oroville plant, Paul Fairbanks, the Plant Manager, shared insights into the ongoing projects aimed at bolstering quality and efficiency. These projects include the introduction of the TOMRA 5A and TOMRA 5B machines, which have become integral in optimizing both production and labor processes.

Fast Facts: Pacific Coast Producers - Oroville, CA Plant

Pacific Coast Producers’ Oroville plant produces canned peaches, pears, fruit cocktail, and fruit bowls. The plant produces 13 million cases per year, equating to 312 million cans and bowls. They now operate the TOMRA 5A and TOMRA 5B sorters in their operations.

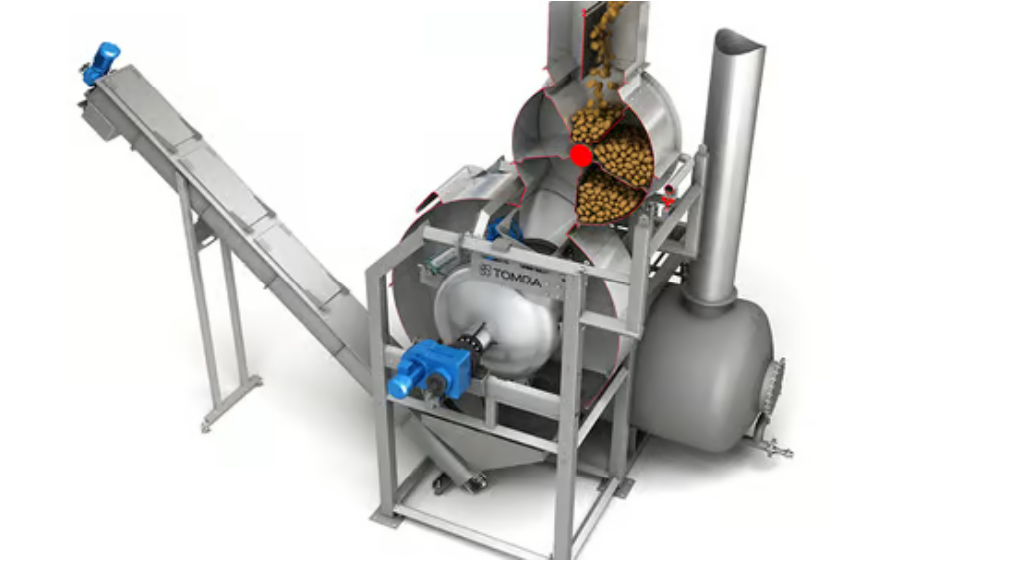

TOMRA 5A

The TOMRA 5A is a robust bulk sorter and size grader that excels in high-capacity, high-performance sorting. It ensures superior yields, running continuously to improve production efficiency. Its versatility makes it an ideal choice for handling a variety of products, including fresh pack potatoes, French fries, potato crisps, beets, brussel sprouts, peppers, gherkins, radishes, and peaches.

TOMRA 5B

The TOMRA 5B combines cutting-edge sensor technology with advanced algorithms, offering unparalleled precision in achieving stringent quality targets and optimizing yields. This high-performance belt sorter is especially effective in sorting delicate and high-value products such as berries, cherries, mangoes, pineapple, stonefruit, dried fruit, almonds, cashews, hazelnuts, peanuts, raisins, walnuts, French fries, potato crisps, beans, bell peppers, broccoli, carrots, cauliflower, corn, garlic, green beans, leafy greens, mushrooms, onions, peas, gherkins, radishes, and spinach.

Sentinel II

In addition to the TOMRA 5A and 5B, PCP also utilizes the Sentinel II machine, which is engineered for vigilant defect detection. Known for its simplicity, cost-efficiency, and durability, the Sentinel II outperforms its competitors in sorting capacity and reliability. It is an excellent choice for products such as green beans, peaches, potatoes, and tomatoes.

With the implementation of TOMRA's advanced sorting technology, Pacific Coast Producers continues to ensure top-tier quality and efficiency in their canned fruit operations while maintaining high standards in both throughput and labor management.

News of TOMRA Food