Catalytic Generators

Cooling and CA

From green to perfect bananas with tried-and-true ripening technology

The German company Fruchtimport vanWylick GmbH, one of Europe’s largest banana ripening operators, has integrated Catalytic Generators’ Easy-Ripe® systems into its large-scale facilities. The company highlights the simplicity, safety, and control this technology offers compared to centralized gas systems, achieving a more efficient, stable ripening process without interruptions in supply

Managing fruit ripening has always been one of the most delicate stages in the fresh produce supply chain. Bringing bananas or other climacteric fruits to the ideal stage of ripeness at just the right time is both an art and a science. Ethylene, a natural plant hormone, plays a central role in this process — but how it is delivered and controlled during the ripening process can make all the difference.

Today, Catalytic Generators are proving to be a flexible and reliable solution for companies seeking efficiency and consistency in their ripening operations, ensuring fruits reach their peak quality when they reach the market.

To see how this technology works in real-world conditions, we spoke with Simon Goisser, Head of CSR and the “Ripening Academy” at Fruchtimport vanWylick — one of Germany’s largest and most experienced banana-ripening companies, positioned among the leading operators in Europe, with a capacity of over 230,000 boxes per week. Simon shared how the company has incorporated Easy-Ripe generators into its large-scale ripening operations, ensuring careful refinement and consistently high fruit quality.

Balancing Tradition and Flexibility

While traditional centralized gas supply systems remain widespread in Germany, many ripening facilities are increasingly turning to Catalytic Generators as an alternative. These systems offer simplicity, operational safety, and consistent results — all without the complexity of piping or high installation costs.

As Greg Akins, CEO of Catalytic Generators, points out, “Ethylene application should not be complicated,” and Simon Goisser fully agrees — the technology allows ripening operations to remain efficient and adaptable without excessive technical challenges.

Beyond efficiency, these systems also serve as a dependable safeguard in case of failures in other ripening setups. “There have been situations where a valve in the centralized gas supply system failed, and by the next morning the cylinders were practically empty. That resulted in both time and financial losses, as customers expect deliveries to arrive precisely on schedule,” recalls Goisser. “If something like that happened with Catalytic Generators, the worst-case scenario would be losing just no more than one or two litres of liquid.”

Ripening chambers at Fruchtimport vanWylick GmbH, Germany.

Ripening chambers at Fruchtimport vanWylick GmbH, Germany.

Not Just for Small Projects

Some in the ripening industry assume that catalytic generators are suitable only for small projects. However, as one of Germany’s largest banana ripening companies, Fruchtimport vanWylick GmbH demonstrates that this technology can play a strategic role even at scale, alongside other ripening systems.

Simon Goisser explains:

“The modular nature of generators makes it much easier to expand capacity. If you start small, with just a few rooms, scaling up is straightforward — you can simply add more rooms and place additional units there. Expanding a centralized system, by contrast, is always more complicated and expensive because of the extra tubing and wiring.”

At the same time, Goisser emphasizes that the key advantages of generators lie in their flexibility and lower entry costs:

“To set up a centralized system with gas cylinders, you need to spend a lot upfront on installation, piping, and fittings. With generators, you simply need to purchase a few units, and after that, operation is straightforward.”

Alongside Simon’s points, Greg Akins, CEO of Catalytic Generators, also confirms that catalytic generators are suitable for all types of businesses — from small farms with limited ripening chambers, to importers, distributors, and even large supermarket chains. As an example, he cites Walmart, which uses over 800 generators across its distribution centers in North America and Mexico, demonstrating the system’s versatility and scalability.

This global presence extends beyond North America — retailers like Coles and Woolworths in Australia have also adopted Catalytic Generators across multiple facilities, proving the technology’s reliability and efficiency on a worldwide scale.

For more information

For more information on pricing, purchasing Easy-Ripe® Generators, or calculating potential annual savings on ethylene, please contact Fresh Produce Instruments – the official distributor of Catalytic Generators’ products in the Netherlands – at info@freshproduceinstruments.com.

About Catalytic Generators

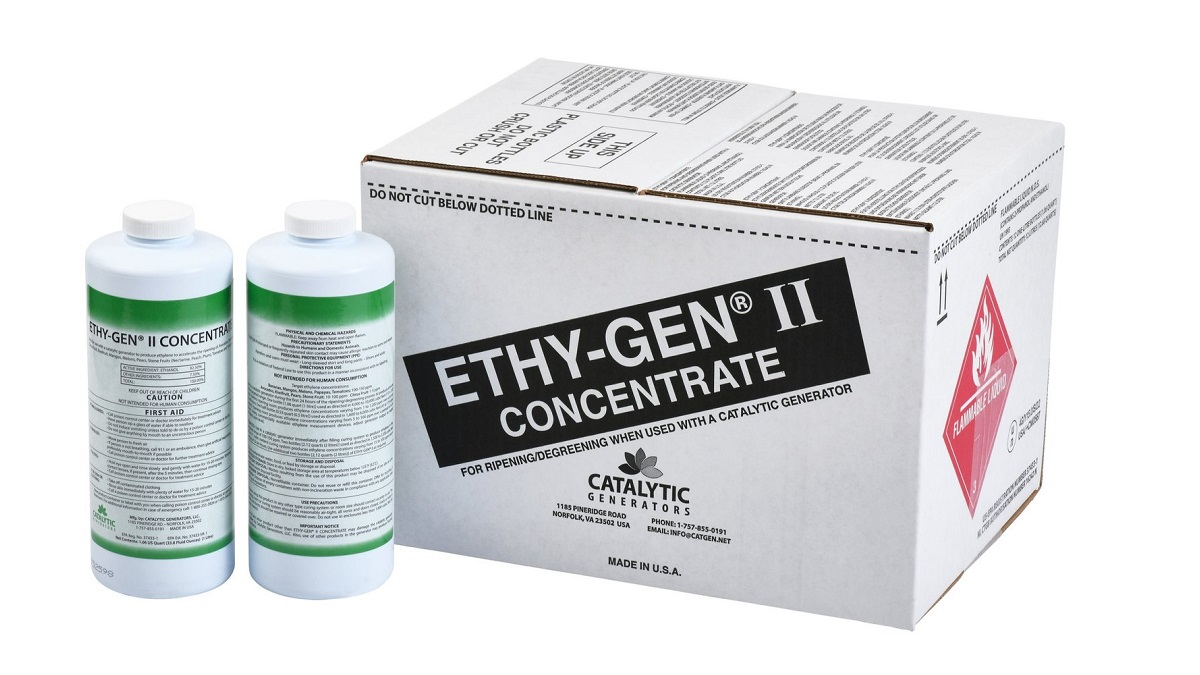

With over 50 years of experience, Catalytic Generators is a family-owned company dedicated exclusively to ethylene application systems and known for making ethylene easy, safe and cost-effective. Based in Norfolk, Virginia, USA, it operates across the globe, supplying fresh produce companies, grocery distribution centers, and growers with the tools to ripen avocados, bananas, tomatoes, and more. It helps customers simplify operations and achieve consistent, predictable results with its high-purity ethylene solutions backed by professional support, local distribution, and customized services. Catalytic Generators’ commitment to quality and customer partnership ensures a reliable and timely supply of ethylene for customers worldwide.

News of Catalytic Generators