Marvil Engineering

Cooling and CA

Controlled atmosphere storage: prolonged freshness without chemical additives

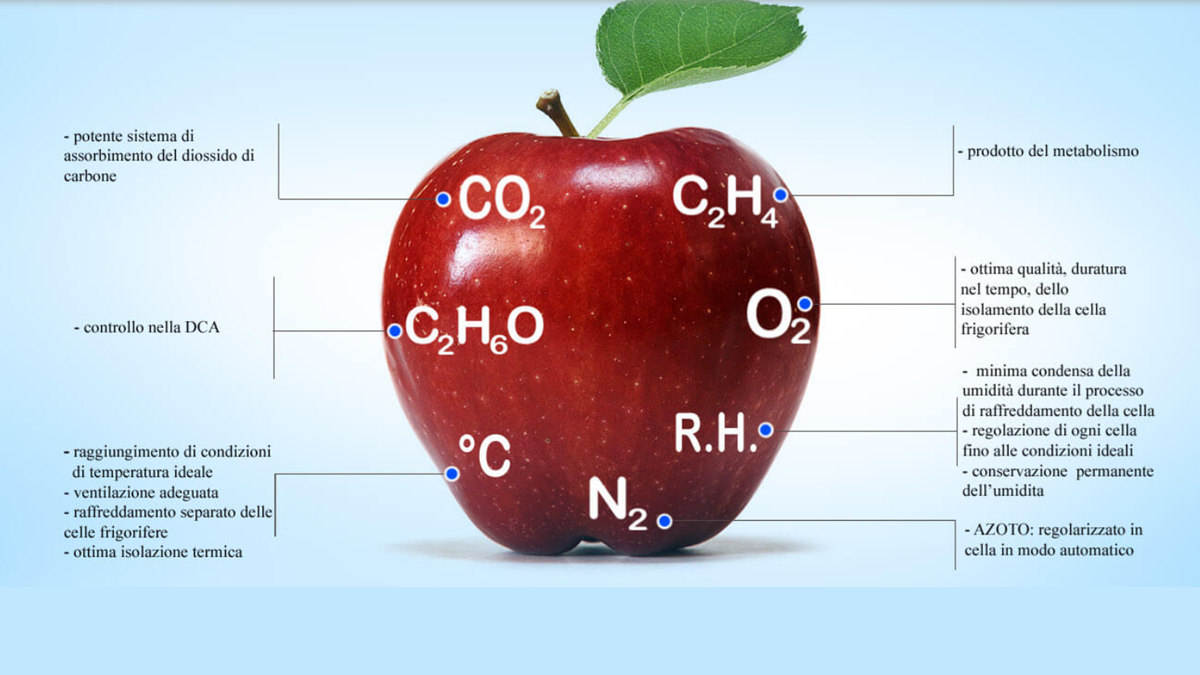

Fruits and vegetables are plant products that remain alive after harvesting: they maintain their active metabolism, breathing, consuming oxygen and producing carbon dioxide, water vapour and other volatile gases, such as ethylene

During cold storage, controlling ethylene and other gases—using controlled atmosphere (CA) technology—along with precise temperature and relative humidity management, allows products to be preserved naturally, without the need for chemical additives. This slows down the metabolism of fruit and vegetables, preserving their freshness, firmness and nutritional value until they reach the consumer.

Slowing down metabolism is key from the moment of harvest. It is therefore essential to minimise the time between harvesting and arrival at the storage facility, and to apply the appropriate treatment from the outset.

The chambers, equipment and technologies developed by Marvil are designed to achieve optimal preservation, allowing fruit to retain its characteristics as if it had just been picked, even after several months. Thanks to the expertise of its specialised technicians, Marvil offers personalised advice on how to preserve each type of product in a simple, effective manner with extraordinary results.

Since 2014, Isofred and Marvil Engineering have joined forces in the design and construction of industrial cold rooms with AC, consolidating a strategic partnership that drives innovation in the sector.

Controlled atmosphere: automation and operational simplicity

The creation of hermetic cold rooms allows for the establishment of sealed environments where key gases such as oxygen, carbon dioxide, nitrogen, and ethylene are precisely controlled. This atmospheric control is essential for extending the shelf life and quality of fruit and vegetables during storage.

In addition, the data transmission system is open and compatible with external management platforms, facilitating integration with other programmes and logistics solutions. For all these reasons, Marvil systems are among the most reliable, simple and advanced on the market.

Over the years, various preservation techniques have been developed based on increasingly lower levels of oxygen and carbon dioxide. From the ULO (Ultra Low Oxygen) system, widely used in the last century, there has been an evolution towards more advanced technologies, such as DCA (Dynamic Controlled Atmosphere), developed in the 2000s.

DCA was developed as an evolution of the ILOS (Initial Low Oxygen Stress) method, designed to combat superficial scalding—a post-harvest physiopathy that mainly affects certain varieties of apples and pears—without resorting to the use of chemicals. This technique involves reducing oxygen levels to values close to anoxia. Although these levels could pose a physiological risk to the fruit if maintained for prolonged periods, their controlled application generates initial “stress” that causes an abrupt slowdown in metabolism and triggers natural self-protection mechanisms.

Thanks to the technology developed by Marvil, this process is applied in complete safety, always remaining above the risk threshold, but with excellent results: surface scalding is completely eliminated and the shelf life of the fruit is significantly extended after storage. Once DCA preservation is complete and the fruit is exposed again to normal atmospheric and thermal conditions, it resumes its natural metabolism and continues its ripening process, reaching the end consumer with optimal flavour and ideal texture.

Marvil systems integrate advanced technologies such as nitrogen generators, CO₂ absorbers and ethylene converters, all managed by computerised analysis and control systems in fully or partially automated plants. This guarantees simple, effective and 100% natural operation, without chemical additives, beyond the precise modulation of the gas composition of the surrounding air.

Practical CA/ULO storage systems for small volumes

For small quantities of delicate products or fruits such as cherries, berries or mushrooms, an efficient solution is to use controlled atmosphere (CA) or ULO systems on individual pallets. Once palletised, the products are placed on special platforms and covered with high-density polyethylene bags, creating an airtight environment.

Each unit is connected to a closed circuit with automatic gas control, allowing for ideal preservation without the need to completely fill a cold room. This flexibility makes it possible to store products daily according to availability and to disconnect a pallet from the system at any time without affecting the rest of the units.

From classic ripening chambers for bananas to those designed for exotic fruits such as mangoes, papayas and avocados, as well as specific chambers for degreening citrus fruits, the systems developed by Marvil guarantee precise control of all critical parameters: temperature, relative humidity, ethylene and CO₂ concentration.

In the specific case of persimmons, in addition to the ripening process, it is possible to apply natural treatments to reduce tannins, thus achieving a fruit with a crunchy texture and sweet taste, ready for consumption without chemical processes.