Marvil Engineering

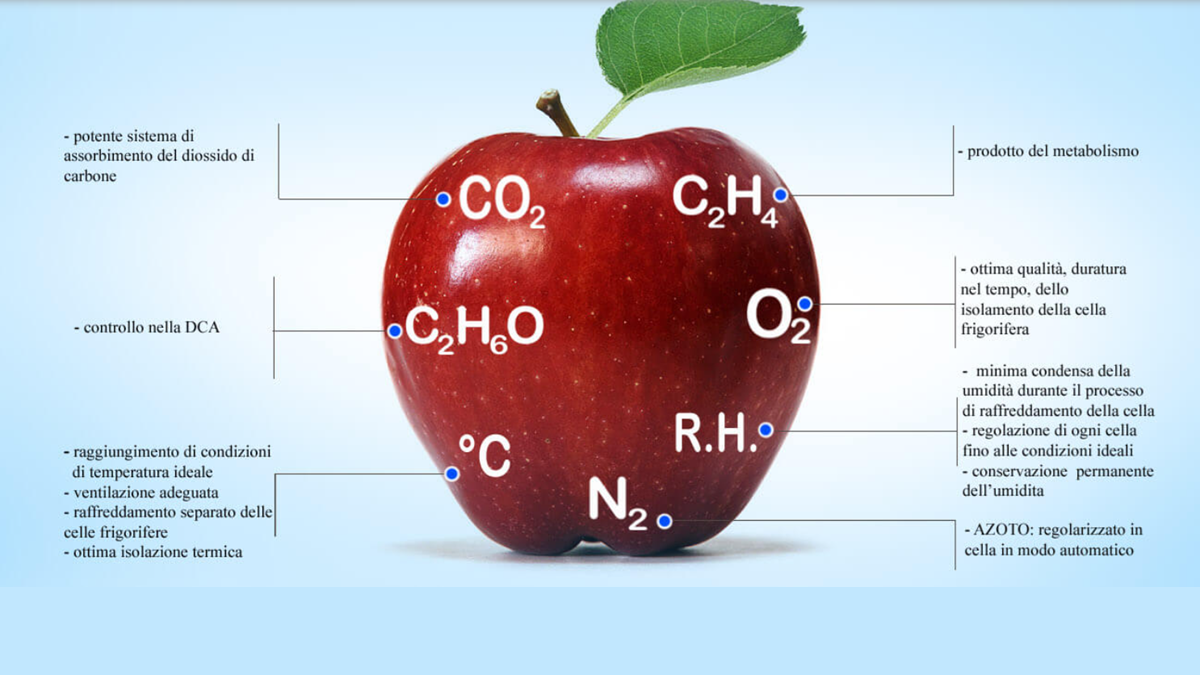

Cooling and CA

Sustainable pest control: maximum effectiveness without environmental impact

In today's food environment, the pressure is doubled for those who manage production: not only must they eradicate pests, but they must also ensure compliance with increasingly stringent legal limits on pesticide residues (see Regulation (EC) No. 396/2005).

Meanwhile, Europe is promoting the use of methods that replace conventional chemicals in pest control (Directive 2009/128/EC), paving the way for systems that work without leaving residues or toxic gases.

Now, thanks to this new generation of technology offered by Marvil, it is possible to comply with regulations, raise hygiene standards, cut costs associated with licenses or traditional insecticides, and defend brand and product reputation.

Marvil Engineering's solution — What they do and how they do it

The Italian company has launched a bold proposal: a system that uses pure nitrogen atmospheres to eradicate pests by suffocation, without resorting to chemicals or toxic gases.

The nitrogen is generated directly on site and introduced into silos or treatment chambers, reducing oxygen to levels below 1% and thus creating a hostile environment for living organisms. In addition to its effectiveness, this method has another essential advantage: it leaves no residue on the treated products.

Customer benefits — What you gain, what problems are solved

Companies that adopt this technology obtain tangible advantages:

- Products free of chemical residues.

- Elimination of the need for special permits linked to the use of toxic gases.

- Reduction in operating costs thanks to the generation of nitrogen at the center itself.

- Maximum effectiveness: up to 100% pest mortality.

- Improved overall hygiene and enhanced brand protection.

- Less dependence on highly specialized personnel for traditional treatments.

How it works — Brief explanation of the process

The process consists of several phases:

- On-site production of pure nitrogen.

- Injection of the gas into the chamber or silo containing the product.

- Reduction of oxygen to levels below 1% to achieve pest eradication.

- Automated control system: oxygen analyzer, monitoring software, and remote management.

- Adjustment of treatment duration according to temperature, humidity, and type of pest.

- Final ventilation that leaves the product pest-free and residue-free.

Why Marvil — Experience and reliable technology

Marvil offers an environmentally friendly, innovative solution with multiple applications in sectors as varied as food, fruit and vegetables, industry, and asset preservation. Its commitment to on-site gas production and robust process automation makes it a trusted partner for companies seeking innovation, regulatory compliance, and operational efficiency.