Paclife

Packaging

Enhancing Food Preservation: The Role of Flow Pack Technology and Paclife's Modified Atmosphere Film

Flow Pack technology and Paclife film revolutionize the preservation of fruits and vegetables by significantly extending their shelf life

Currently, the quality and freshness of food products are crucial, making packaging technology play a fundamental role. They are no longer merely "containers" but vital tools to ensure they reach their destination in perfect condition. Flow Pack technology, combined with Paclife's patented modified atmosphere film, emerges at the forefront of food preservation.

Oxygen, ethylene, fungi, and insect pests are just a few agents that can deteriorate food from the moment of harvesting until consumption. This degradation not only affects the nutritional value and organoleptic characteristics of the products but also compromises their microbiological safety, leading to withdrawal and disposal. In response, packaging has become a powerful tool in the global horticultural industry.

Revolutionizing shelf life

Flow Pack, a type of flexible packaging known as horizontal packaging, stands out for its versatility and cost efficiency. Its adaptability to various sizes and shapes enables manufacturers to package a wide variety of products with the same type of packaging. Furthermore, its hermetic sealing protects food from moisture, light, and air, significantly extending its shelf life.

In Chile, this technology utilizes Paclife's patented modified atmosphere film, a revolution that reduces microbial growth and the speed of internal chemical reactions that affect food quality. This modified atmosphere, composed of a gas mixture like O2, N2, and CO2, achieves two objectives: reducing respiration rates and preventing microbial growth.

Solid technical development

Paclife works closely with its partners in Flow Pack technology. The immediacy of packaging tons of fruit, including blueberries and cherries, currently produced in South America, tolerates no errors or delays. They must be packed quickly and efficiently. Thus, from a conservation standpoint, this technical development also provides benefits, contributing to longer fruit shelf life. These benefits include:

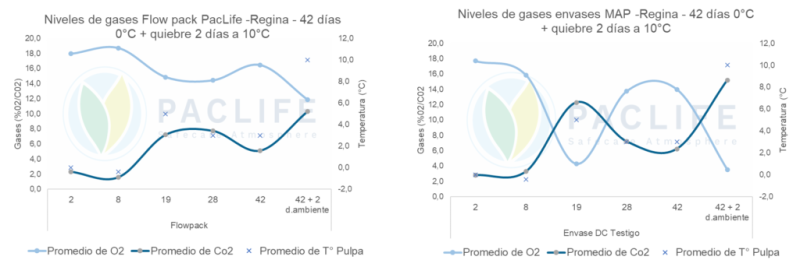

- More stable gases during storage time. Thanks to the properties of the MAP film patented by Paclife, the atmosphere's formation remains intact during transportation, proving to be safer than traditional packaging.

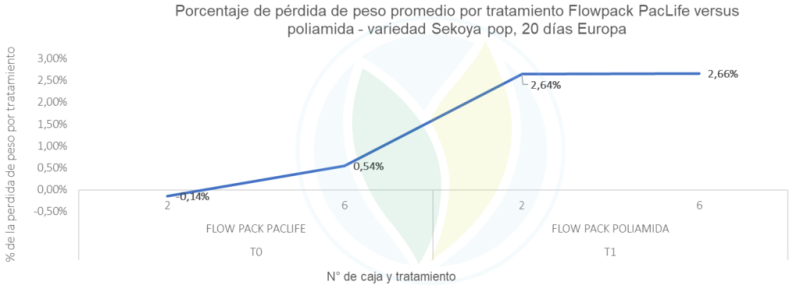

- Less weight loss. Due to its selective water vapor permeability and Paclife additives, weight loss is virtually negligible.

- Reduced browning in sensitive varieties. An essential parameter in varieties like Regina, where Flow Pack, with its stable atmosphere, creates an ideal environment to decrease the incidence of this defect, which increases with temperature fluctuations.

- Increased resistance to temperature fluctuations. An important parameter for demanding markets and retail formats.

Hence, Flow Pack technology with modified atmosphere stands out as the leading solution, not only in terms of automation but also for the preservation of high-quality fruits and vegetables. It offers stability, cost efficiency, and a significant increase in the shelf life of food products. In a world where quality is essential, these packages not only protect but also promote excellence in the global food chain.