Sorma Group

Packaging

Sorma Group at Macfrut: Advanced Postharvest Solutions for Apples and Citrus Fruits

From advanced optical grading to automated packaging: customized solutions for apples and citrus fruits will take center stage in Rimini, May 6–8

.jpg)

Sorma Group, a global leader in the design and production of integrated postharvest solutions for fruit and vegetables, will participate in Macfrut—the international trade fair dedicated to the fruit and vegetable sector—taking place in Rimini from May 6 to 8. The company will showcase its high-performance technologies designed to cover the entire posharvest process, from processing to palletizing.

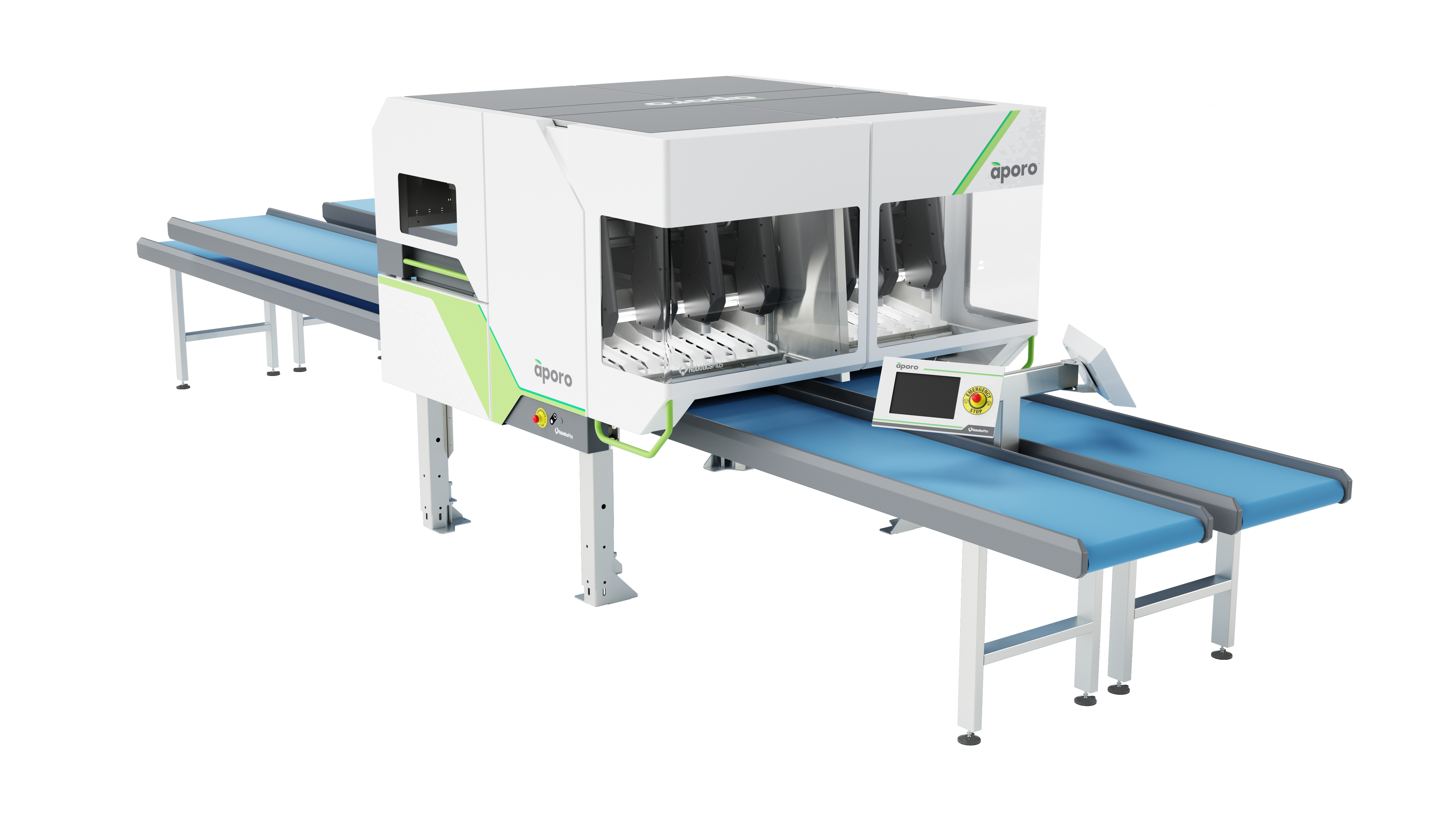

The solutions on display will focus on two strategic value chains: apples and citrus fruits. Among them is Aporo, a multi-head robotic system developed by Sorma Group for automated packaging. It can place up to eight fruits simultaneously into cavities, ensuring consistent orientation and showing the best side—the one with the most intense coloration. This machine guarantees gentle and precise handling, significantly reduces labor costs, and, thanks to its versatile design, supports a wide variety of fruit types including apples, peaches, nectarines, plums, and kiwis. Aporo also enables direct packaging of fruit into pre-inserted cavities in boxes, ensuring maximum flexibility and efficiency.

Visitors will also be able to see HyperVision in action—a high-tech optical grading platform that uses a nine-camera system per line and 360° hyperspectral imaging for precise fruit classification, processing up to 15 units per second on each line. The latest version of HyperVision includes the InstanDefect-AI software, enhanced with deep learning algorithms for even more accurate detection of ripeness levels and potential defects. Built on a Linux software platform, the optical grader ensures operational independence, advanced cybersecurity, and a fully scalable system.

Alberto Agostini, Area Manager at Sorma, says:

“Sorma Group is also working on developing a fully integrated apple processing line—from bin dumping to palletizing. This project aims to deliver a ‘turnkey’ solution, made possible in part by the work of our French subsidiary SORMAF, which is actively engaged in sector innovation.”

Solutions for the citrus sector will also be showcased, featuring two high-performance combined machines: the WD4-S weigher and the CBR-170S packaging machine. The former, compact and powerful, can feed up to four packaging machines with extremely high accuracy, high speed, and adaptability to varying calibers, making it ideal for all citrus types. According to specific needs, Sorma Group offers the most suitable model, with a choice of ten different options, split between dynamic cup weighers and static vibrating channel weighers.

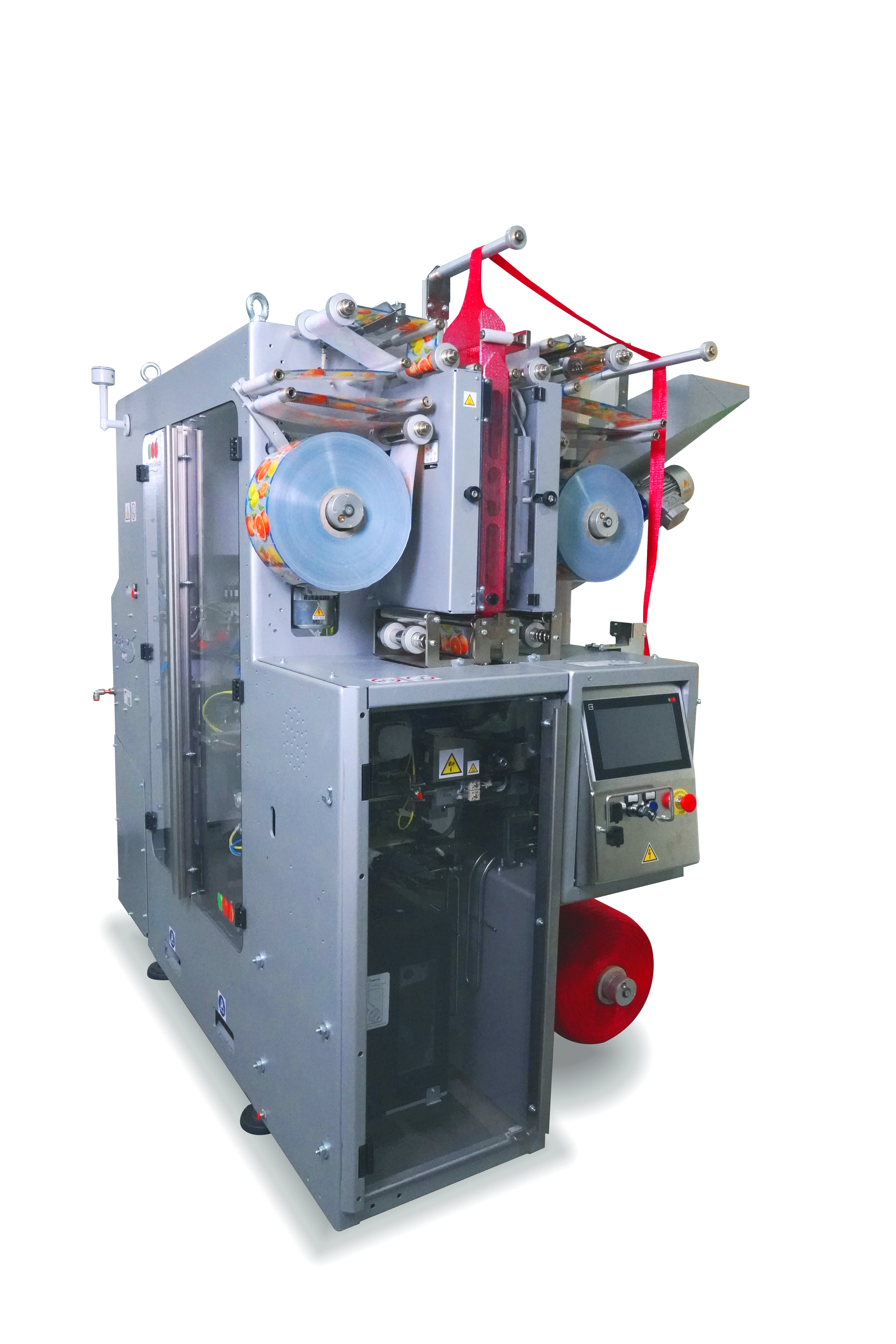

Alongside it, the CBR-170S (Speed) packaging machine has been fully updated for greater speed, precision, and reliability, thanks to several technical improvements: a new band-centering system with both UV and black mark photocells; an upgraded suction and bellows system to optimize bag formation and filling; and new sealing jaws that significantly improve package closure. The machine works with high-capacity woven mesh rolls, replacing traditional single rolls or spools. This upgrade—from 1,300 meters to up to 3,500 meters—eliminates frequent stops due to mesh rewinding and significantly reduces operator intervention. The CBR-170S is microprocessor-controlled and features an intuitive touch interface. It can produce mesh bags with customizable side bands and optional accessories like a carrying handle or thermal printing, offering versatile adaptation to packer needs. A winning combination designed to meet the growing demands of modern retail with efficiency, sustainability, and continuity.

Meet Sorma Group at Hall D.1, Booth 147.

About Sorma Group

Sorma Group has been operating since 1973 and is currently the only business group in the world capable of providing a complete “turnkey” line of machines for the automatic grading, weighing, and packaging of fresh produce, along with the appropriate technical materials to create all types of packaging. We offer more than 160 models of automatic machines, protected by 60 patents, all fully developed by an in-house team of 35 engineers. With maximum precision and reliability, over 30 different fruit and vegetable varieties can be selected and “dressed” to meet the increasingly demanding requirements of large-scale retail (GDO). The Group has its own operational facilities in Spain, Germany, France, Turkey, the Netherlands, the United States, and Brazil. These subsidiaries are supported by a global network of more than 40 specialized distributors.