Sorma Group

Conditioning

Sorma optimises every stage of the processing and automation of fresh fruit and vegetables

Sorma Group, with over 50 years of innovative experience, drives the success of its customers. Thanks to the synergy of its six production centres and the know-how of a large team of engineers, we design and manufacture complete lines of automated machinery for the post-harvest processing of fruit and vegetables, integrating technical materials for packaging.

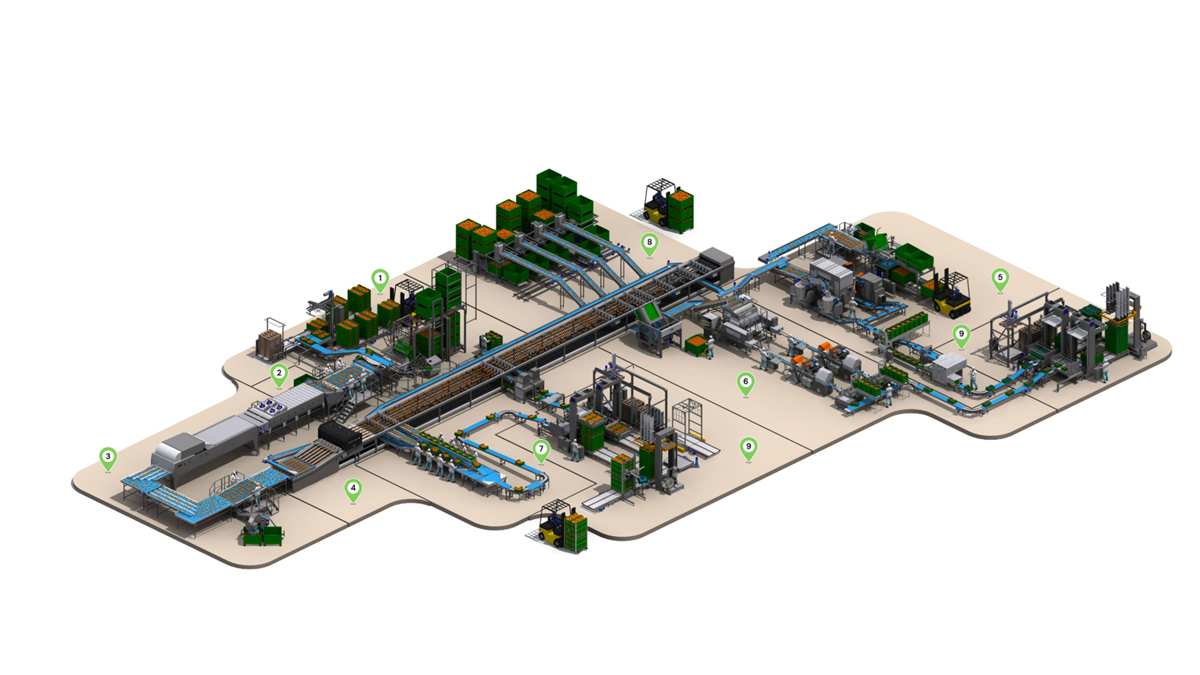

Its commitment includes comprehensive after-sales service, provided by specialised technicians through on-site and remote assistance. The 3D model presented on the cover reflects the most advanced and complete processing plant, with modular and customised lines to adapt to the specific needs of each customer.

Infeed

The fresh produce packaging process begins with feeding the lines, which receive fruit directly from the fields or cold storage rooms. For delicate fruits, such as apples and pears, gentle handling is employed using bin tippers and water channels, which minimise the risk of damage. For less sensitive products, box tippers, self-regulating pallet tippers and big bag emptiers are used.

Among the main machines in this phase are box tippers, self-regulating pallet tippers and bin dumpers.

Presorting

The pre-selection phase, both manual and mechanical, is essential to ensure optimal performance of the optical sorting line. At this stage, products unsuitable for sale, such as rotten or damaged fruit, as well as foreign elements such as leaves, stones and soil, are removed. To improve productivity, we recommend incorporating a mechanical pre-calibrator, with a fixed or variable diameter, which separates small fruits from the processing flow.

Among the machines used are the leaf removal grid, manual pre-selection tables and mechanical pre-sorting systems.

Treatments, screening, calibration

These treatments remove dirt and bacteria, delay fruit ripening and improve its external appearance. In this phase, brushes with an innovative release system are used, designed to facilitate cleaning. Both the individual model and the combination of machines are fully customised according to the characteristics of the product and the requirements of the process.

The equipment used includes brushers, washers, fungicide systems, waxers, polishers, drying tunnels and other specialised systems.

Optical sorting

The heart of the entire processing plant is the optical sorter, as it guarantees consistent quality over time, reduced waste and a significant increase in profits. To ensure the best computing performance, each line of the sorter is controlled by a dedicated industrial PC capable of processing more than 3.7 GBytes of information in real time. Each Linux-based PC manages 9 video cameras that produce 108 images per fruit at 15 fruits/second, for a total of 1,620 shots per second per line. The combination of all hardware and software components allows us to sort the entire surface of the fruit by: internal and external quality, colour, shape, diameter, density and weight.

Bags, baskets and boxes

Bags are undoubtedly the most widely used flexible packaging for fruit and vegetable products weighing more than half a kilogram. They offer the best performance in terms of strength, visibility and shelf life. Depending on the product, they can be made of mesh or film: mesh bags are ideal for allowing air exchange in products such as citrus fruits, potatoes and onions, while film bags maintain moisture in products such as carrots, celery, radishes, lettuce and apples.

Baskets are the perfect packaging for delicate fruit and vegetables, as they protect the product and extend its shelf life. Some models are stackable and our machines process cardboard baskets (with or without flaps), polypropylene, polyester and clamshell baskets. We offer automatic or semi-automatic lines depending on the type of product and processing required.

Boxes, on the other hand, are adapted to the product and the aesthetic requirements of the end customer, and can be filled in bulk, packaged or in honeycomb form. We produce customised automatic filling systems as well as manual filling benches. We also manufacture net bags to protect the contents during handling in the shop or to add value to the product.

The machines used in these phases include weighers, packers, netting machines, baggers, counters, destackers and filling systems, adapted to each type of packaging and product.

Access the complete information here

.jpg)