TOMRA Food

Conditioning

Cherry packhouses experience the efficiency and profitability benefits of TOMRA LUCAi™ deep learning technology

Cherry packers in California, USA, and New Zealand implemented TOMRA’s AI-powered LUCAi™ technology with their InVision 2 grading platform during the past two seasons with excellent results. They increased production and packing efficiencies while minimizing waste and maintaining the high quality of the product. The user-friendly interface made it easy for operators to adapt to the new technology

Prima Frutta Packing is a family-owned business based in Linden, California. It packs high-quality cherries using the latest packaging technologies to ship across the USA and internationally to markets in Asia and other regions. It was founded in 1991 by Tim Sambado to pack the produce from orchards on and around the family’s ranch, which is marketed by Primavera Marketing, also run by the family.

The business has grown steadily and ten years ago it introduced TOMRA Food sorters into its processing line to achieve the quality demanded by its customers. Tim Sambado, President of Prima Frutta, explains:

“We pride ourselves on our consistent quality, day in day out, season to season. Our customers look for us to deliver a high-end quality product as well as excellent service. We can’t do our business without technology and information. We are obsessed with data, and we are obsessed with getting the best technology in the world.”

In 2023, TOMRA Food was in the final stages of development of its AI-powered LUCAi™ platform, ready to trial its innovation with customers in different conditions and regions – from California to New Zealand. When Prima Frutta was offered the opportunity, Tim Sambado, a keen believer in technology, was eager to see how it could help him achieve the improvements he wanted for Prima Frutta:

“We wanted to become more accurate, to simplify the system for our operators, and to be able to detect some defects that in our traditional mapping system was more difficult.”

After the 2023 cherry season, Prima Frutta decided to install LUCAi on all of their machines, for a total of 132 lanes for their upcoming 2024 cherry season.

Two long-standing customers who have been running TOMRA equipment for almost 10 years, both based in Central Otago, New Zealand, were also keen to implement the TOMRA LUCAi™ technology on their InVision 2 grading platform: Dunstan Hills, which grows cherries primarily for export around the world and Panmure Orchards, a family business founded in 1952 and now in its sixth generation, which serves the domestic market.

The three cherry growers share the challenge of meeting the growing demand, with consistent high-quality produce, in the short cherry season, which typically begins in mid-May and finishes at the end of June in California, while in New Zealand it runs from early to mid-December to late January. After one full season with TOMRA LUCAi™, they found that they benefited from higher productivity, enhanced quality selection with consequent higher margins for their customers, and reduced food waste. Ian Nicholls, Operations Manager at Dunstan Hills, says:

“With LUCAi™ we achieved better grading and increased throughput of around 10 percent – and it is easy to use,”.

User-friendly operation, high quality, increased productivity

LUCAi™’s user-friendly interface software makes it very easy for the customer’s operators to get the best sorting and grading performance from their processing line. Tim Sambado explains:

“It allows us to make changes and gives us accurate data on how it is going to impact our grading before we apply the change. This means that the operators can do things with much more confidence and quickly. They don’t have to do a lot of sampling and testing before they can apply a change because they get the data immediately. This immediate feedback is a game changer, because in the cherry world, when you’re running 40,000 cherries a minute, you just don’t have a lot of time to sample.”

Ian Nicholls agrees:

“It is easier for the operator to refine decision-making and improve grading. LUCAi™ is better at making difficult decisions on small blemishes as to whether it is for export or the local market.”

This not only helps cherry packers deliver consistent quality and meet the specific requirements of their customers, but it also enables them to increase their productivity and address the short cherry season. Ian Nicholls says:

“With LUCAi™ making more accurate decisions, we are able to put more fruit in front of the sorters.”

Tim Sambado agrees:

“We are running more tons per hour with the same labor force, allowing us to keep up with the cherry harvest, which is quite compact in California. We also continue with the quality that we expect in our brands. One of the advantages of LUCAi™ is that when we depend on electronic sorting to do all the heavy lifting, the number of good-in-bad errors has been dramatically reduced.”

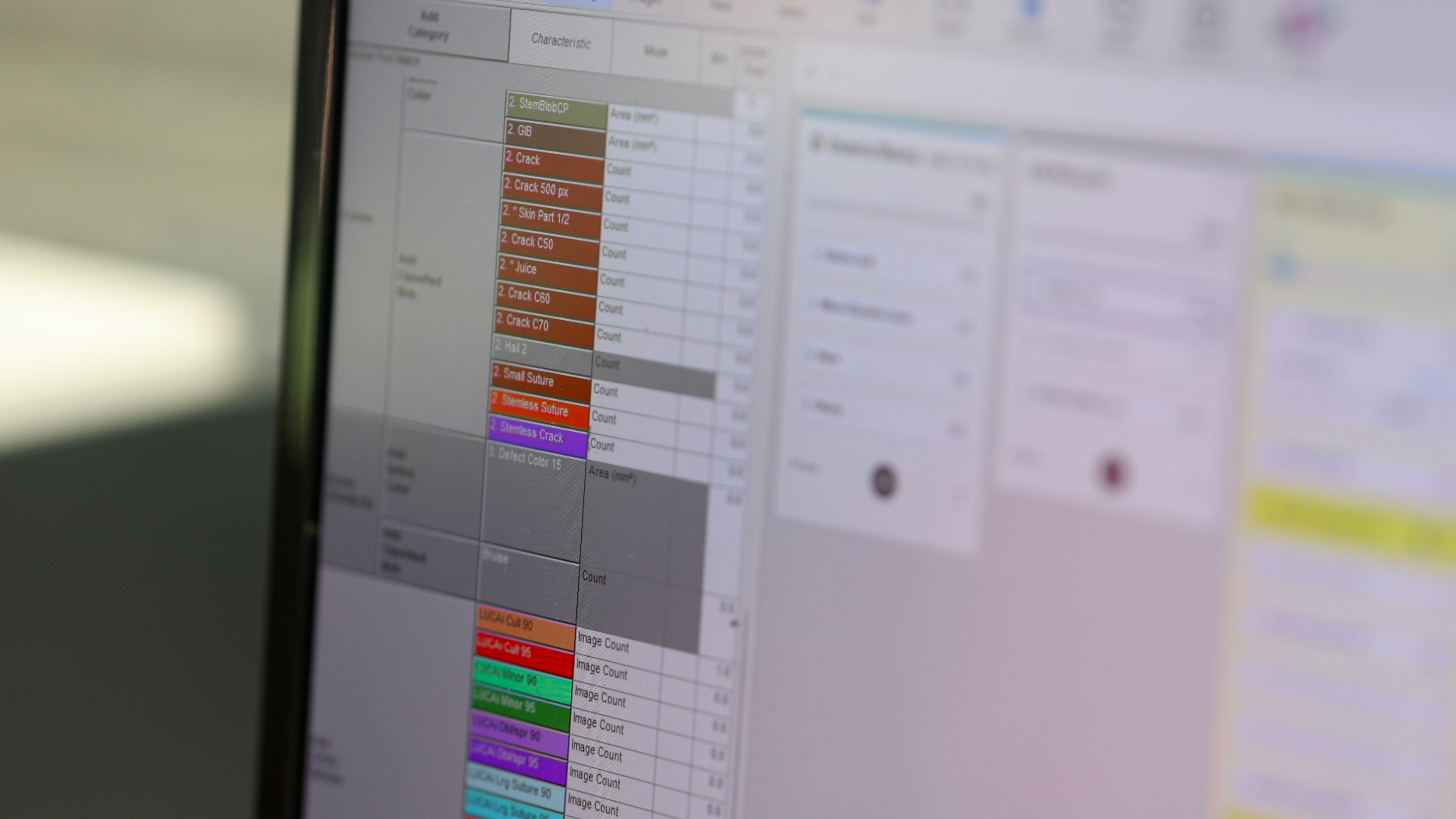

Unparalleled accuracy, future-proof technology

LUCAi™ for the InVision 2 cherry grading platform is unique in that it comes with vast amounts of data collected by TOMRA in different regions across the world, building pre-trained models using real images of cherries. This means that it is ready to deliver its superior sorting and grading performance as soon as it is installed. It uses TOMRA’s Deep Learning technology to identify with unparalleled accuracy an extensive range of defects – from edge cracks, Pacman cherries, open sutures, cosmetic blemishes and stem pulls, to spurs, cracks and all defects around the stem; from dehydration to pical splits; and it will recognize colors in the ripe phase with precision. Jeremy Hiscock, Managing Director at Panmure Orchards is impressed with the accuracy:

“We have seen a significant increase in the quality of machine graded fruit with LUCAi™. We would be devastated to not have access to this technology.”

The platform also continues to evolve as it keeps learning from the data it collects while running in the customer’s operation, future-proofing their business. TOMRA’s Service team remains at their side after installation, ready to proactively help them optimize their sorting and grading performance. For example, they can access the platform and use its data and the customer’s feedback to build defect models to perform for their specific needs and quality requirements.

Tim Sambado says:

“It’s an evolving process. Teaching it the powdery mildew defects, insect bites, freshwater cracks that we’ve had after a rain: things that were very difficult on our traditional mapping systems. The LUCAi™, through training, has seemed able to get these types of specialized defects more effectively.”

“It’s really exciting to see how the system is going to evolve. I think we’ve just scratched the surface and there’s a lot more ahead of us. TOMRA Food is our partner, we continuously try to get better together. As we move into the future, we clearly realize as a company that we all have to keep getting better. Expectations keep going up, everybody expects a better product, delivered on time, without any excuses. TOMRA Food technology will help us meet those demands”.

Benedetta Ricci Iamino, Global Category Director – Cherries at TOMRA Food, summarizes:

“Thanks to LUCAi™, the era of compromise is a thing of the past for our customers. It guarantees the packaging of top-notch fruit, meticulously sorted and placed in optimal boxes, prepared for the most favorable market prices. LUCAi™ excels at handling various cherry qualities with precision, consistently segregating fruit classes for different markets, even in challenging batches, thus preventing fruit waste and potential market claims. The commitment is crystal clear – our customers can now confidently expect their best fruit, in prime condition, reaching optimal markets, all at highly competitive prices. LUCAi™ caters to a diverse range of preferences and customizations, providing a comprehensive solution poised to revolutionize the industry landscape and enable our customers to achieve unprecedented success in the cherry industry.”

In this video, Tim Sambado of Prima Frutta Packing talks about his experience with TOMRA Food.

About TOMRA Food

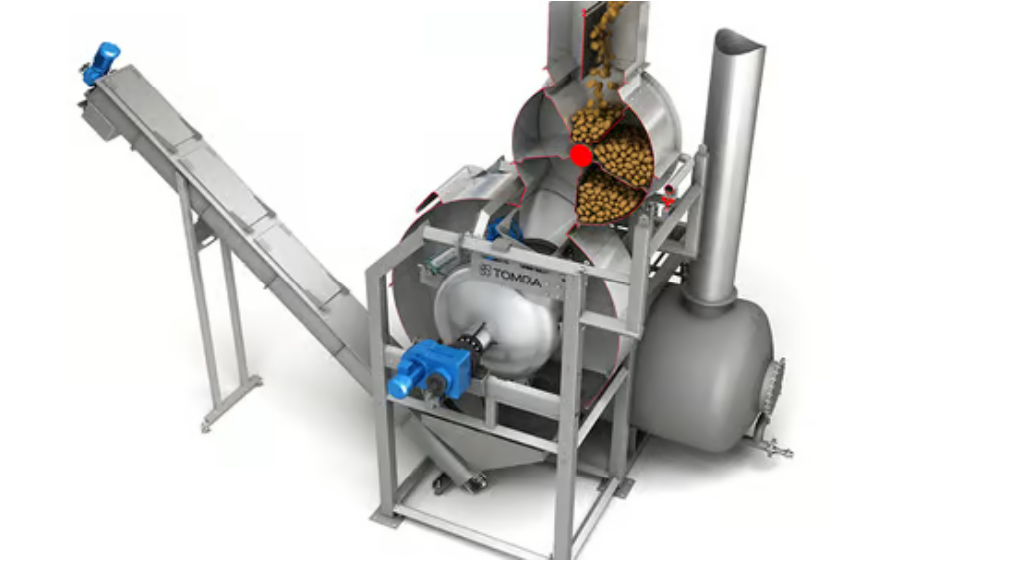

TOMRA Food designs and manufactures sensor-based sorting machines and integrated post-harvest solutions transforming global food production to maximize food safety and minimize food loss, by making sure Every Resource Counts TM .

The company has more than 13,800 units installed at food growers, packers and processors around the world for Confectionery, Fruit, Dried fruit, Grains and Seeds, Potatoes, Proteins, Nuts, and Vegetables.

These solutions include advanced grading, sorting, peeling and analytical technology to help businesses improve returns, gain operational efficiencies, and ensure a safe food supply.

TOMRA Food operates centers of excellence, regional offices and manufacturing locations within the United States, Europe, South America, Asia, Africa and Australasia.

Follow TOMRA Food on Facebook @TOMRA.Food, X @TOMRAFood, Instagram @TOMRAFood, LinkedIn at TOMRA Food and YouTube at TOMRA Food..

TOMRA Food is a division of TOMRA Group. TOMRA was founded in 1972 that began with the design, manufacturing and sale of reverse vending machines (RVMs) for automated collection of used beverage containers.

Today, TOMRA is leading the resource revolution to transform how the planet’s resources are obtained, used and reused to enable a world without waste. The company’s other business divisions are TOMRA Recycling and TOMRA Collection.

TOMRA has approximately 105,000 installations in over 100 markets worldwide and had total revenues of about 12 billion NOK in 2022. The Group employs 5,000 globally and is publicly listed on the Oslo Stock Exchange. The company headquarters are in Asker, Norway.

For further information about TOMRA, visit www.tomra.com.

News of TOMRA Food