TOMRA Food

Conditioning

TOMRA Food technology guarantees safety and quality of organically farmed packaged salads at Italian association of producers "La Maggiolina’"

Tino Bellina, founder of OP (Association of Producers) La Maggiolina and pioneer of the fourth range, revolutionized the way lettuce is consumed, making packaged, ready-to-eat lettuce popular around the world. He transformed the provinces of Bergamo (Northern Italy) and Salerno (Southern Italy) into bastions of Italian horticulture, earning him recognition as a trailblazer on par with Steve Jobs. Today, Bellina continues his legacy of innovation and excellence in the baby leaves sector with TOMRA sorters at OP La Maggiolina

Tino Bellina has spearheaded the greenhouse lettuce industry for 35 years, earning the nickname "The Steve Jobs of the fourth range". He revolutionized the market in the late 1980s by introducing pre-washed baby leaves in bags, fundamentally altering the landscape of the fruit and vegetable industry. This visionary insight prompted him to invest in a packaging machine for bagging lettuces grown initially in Bergamo and later in the Piana del Sele, near Naples, where baby leaves mature in half the time. This ensured year-round production, which he marketed under the Ortobell brand. The turning point came in 2001 when, at the peak of his success, he sold Ortobell to French multinational Bonduelle.

At this time, Tino Bellina identified a growing demand for packaged salads produced with high- quality organic farming practices and established OP La Maggiolina, which he runs with his children Marzia and Manuel, and son-in-law Davide. The cooperative, founded on principles of quality and safety, continues his legacy of excellence in the baby leaf sector. OP La Maggiolina operates in Lombardy, Veneto, and Campania with 14 associated producers and 320 hectares of greenhouses, 200 of which dedicated to organic farming, and three production facilities in Martinengo, Eboli, and Mira. The cooperative, which prides itself on the high quality of the products it delivers to consumers, has successfully integrated TOMRA Food sorters into its operations. These machines use advanced sensor technology to identify and select lettuces, valerian, arugula, and spinach with minimal waste.

Cutting-edge technologies to meet industry challenges

The decision to embrace cutting-edge technology, such as TOMRA Food sorters, reflects a broader commitment to tackling the many challenges of the fruit and vegetable sector. They include the escalating costs of energy, compliance with the Sustainable Development Goals outlined in the 2030 Agenda, and the ongoing struggle to secure skilled labor. With state-of-the-art technology such as TOMRA's, every leaf is meticulously analyzed at great speed, resulting in a clean and safe product.

Tino Bellina stated:

“TOMRA machines have revolutionized our sorting processes, increasing efficiency and minimizing waste. Each leaf is meticulously evaluated, ensuring that only the finest produce reaches consumers tables.”

TOMRA sorters offer multiple benefits, including maximum food safety, superior product grading, optimized production line capacity, and user-friendly operation. This technology delivers greater consistency in product quality while allowing the redeployment of employees previously working in manual grading to more critical areas of the production line.

Gianluca Coloretti of TOMRA Food Italia said:

"In the search for innovative food sorting technologies to meet evolving consumer demands, TOMRA solutions are proving remarkably efficient across diverse applications, especially in the fruit and vegetable sector. Optical technology automates the sorting process, increasing the quality and productivity of the production line. In addition, it maintains a consistent standard of inspection, increasing the safety of food products arriving on supermarket shelves."

Tino Bellina with Gianluca Coloretti from TOMRA

Coloretti also highlighted the importance of TOMRA Food's collaboration with Filippo Mantegazza's Interideatre for its expertise in weighing and packaging lines:

“We at TOMRA Food and Interideatre, share the objective of guaranteeing service excellence, leveraging our collective expertise to facilitate future automation project for new lines and supporting the success of OP La Maggiolina".

New paths and environmentally friendly opportunities

OP La Maggiolina continues to address market challenges by diversifying its offering with the production of premium organic baby leaves. These high-quality products are exported to the European market, providing a significant revenue stream for the cooperative. This strategic move enables OP La Maggiolina to address the pricing pressure exerted by large-scale distributors on the domestic market.

The cooperative remains proactive towards new forthcoming challenges, in particular with regard to environmental protection. Its research into new packaging materials, now at an advanced stage, aims to cater to customer preference for plastic-free containers and align with the evolving regulations of the European Agenda 2030. Innovation never stops at OP La Maggiolina, leading the cooperative to cutting-edge technologies such as TOMRA Food’s in its pursuit of high standards of food quality and safety for its customers.

About TOMRA Food

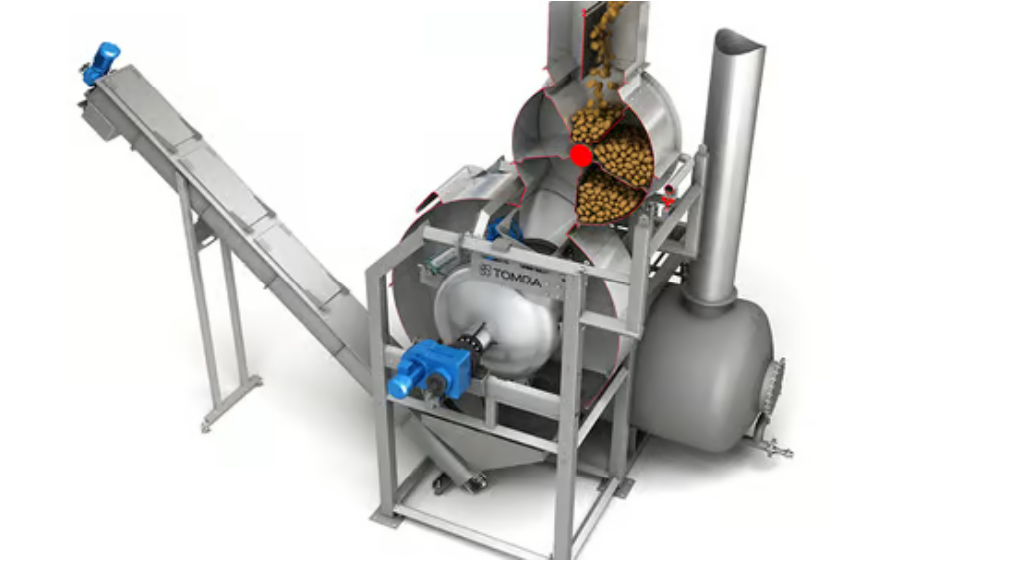

TOMRA Food designs and manufactures sensor-based sorting machines and integrated post-harvest solutions transforming global food production to maximize food safety and minimize food loss, by making sure Every Resource Counts TM .

The company has more than 13,800 units installed at food growers, packers and processors around the world for Confectionery, Fruit, Dried fruit, Grains and Seeds, Potatoes, Proteins, Nuts, and Vegetables.

These solutions include advanced grading, sorting, peeling and analytical technology to help businesses improve returns, gain operational efficiencies, and ensure a safe food supply.

TOMRA Food operates centers of excellence, regional offices and manufacturing locations within the United States, Europe, South America, Asia, Africa and Australasia.

Follow TOMRA Food on Facebook @TOMRA.Food, X @TOMRAFood, Instagram @TOMRAFood, LinkedIn at TOMRA Food and YouTube at TOMRA Food..

TOMRA Food is a division of TOMRA Group. TOMRA was founded in 1972 that began with the design, manufacturing and sale of reverse vending machines (RVMs) for automated collection of used beverage containers.

Today, TOMRA is leading the resource revolution to transform how the planet’s resources are obtained, used and reused to enable a world without waste. The company’s other business divisions are TOMRA Recycling and TOMRA Collection.

TOMRA has approximately 105,000 installations in over 100 markets worldwide and had total revenues of about 12 billion NOK in 2022. The Group employs 5,000 globally and is publicly listed on the Oslo Stock Exchange. The company headquarters are in Asker, Norway.

For further information about TOMRA, visit www.tomra.com.

News of TOMRA Food