ULMA Packaging

Packaging

ULMA Packaging will be showcasing the latest developments in automation and packaging process efficiency improvements for the food industry at Anuga FoodTec 2024

ULMA Packaging at Anuga FoodTec 2024 will showcase sustainable, innovative, and Industry 4.0-ready solutions

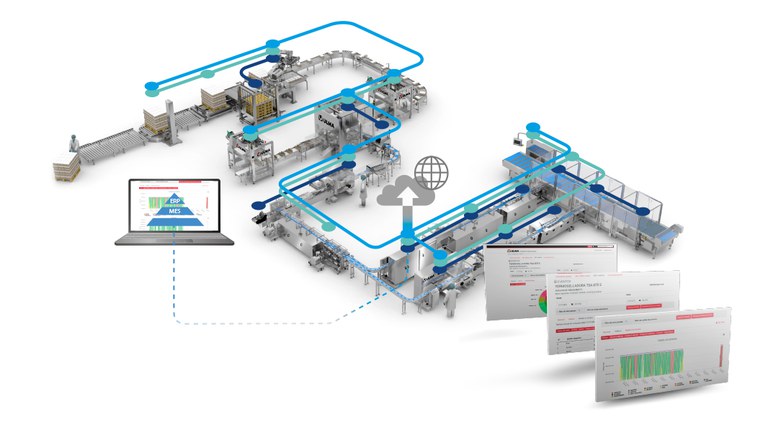

With automation and digitalisation as keys to increasing the efficiency of the packaging process, at its 600 square metre stand, ULMA will be showcasing sustainable and innovative solutions that are ready to be integrated into production plants thanks to advances in Industry 4.0.

Fully Automated Lines

Tray sealing packaging line for fresh products

One major requirement of customers is to have a single source supplier of comprehensive packaging solutions that are integrated into their production process.

To meet this need, by way of a practical example, ULMA will be exhibiting a high-output traysealing line with automatic product loading and case packing.

Additionally, thanks to the ULMA Line Control system, visitors will be able to see how all phases of the process are efficiently managed from a single central point.

More info about ULMA Digital Solutions - here

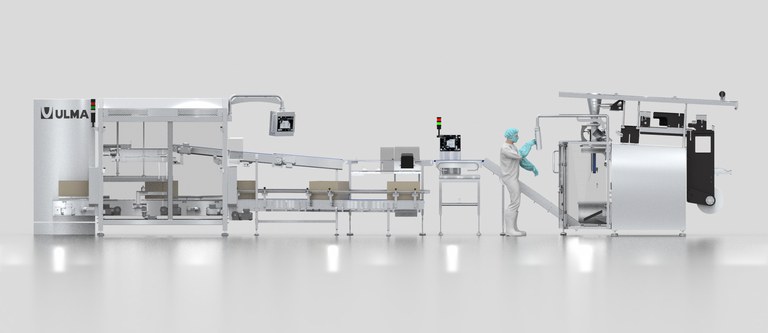

Vertical bagging line (VFFS) for fresh and frozen products

A line consisting of a VTC 840 vertical packaging machine with a wash down design and an automatic gravity case packer will be on display.

Special features of the bagger include the Tight-BagTM technology to optimise bag volume and the SealFlexTM system to reduce maintenance costs through quick jaw changes.

The Tight-BagTM technology featured in the bagging machine is compatible with various types of sustainable film, achieving optimal pack sizes that lead to significant savings in logistical costs, both in storage and transportation.

Basic solutions for small and medium-sized processors

Every company has its own needs and not all processors and producers require high-performance end-to-end solutions. Therefore, ULMA will be exhibiting a range of machines and compact solutions for the food industry.

Two compact and versatile traysealers capable of packaging fresh food and ready meals in MAP and SKIN will be on display along with a TFS 200 S thermoforming machine for SKIN applications that is designed to work with different types of materials such as mono-material films, laminates or cardboard.

Hall 8.1 | Stand A020 – B039

Come and visit ULMA at Anuga Foodtech 2024. We will be delighted to show you the latest technologies in automation, sustainability and Industry 4.0 so that we can offer you best solution to suit your needs.