Grup Giró

Packaging

Advances in Cellulose Packaging, a Commitment to the Environment

Grup Giró presents its advancements in cellulose packaging as a sustainable alternative to plastic net packaging

In recent years, concern about environmental conservation has become a central issue for public opinion. Governments and environmental associations are mobilizing to replace conventional plastic packages with options like paper or cellulose. However, there are two versions of clipped cellulose packages: Wineglass (WG) and Clip2clip (C2C).

While it is true that the use of plastic in packaging should be controlled and reduced as much as possible, we cannot forget that its use brings many environmental benefits: usually, plastics are lighter than other alternative materials; often have a better optimization of resources, making the relationship between packaging vs. packed content more efficient; it allows being more cost-effective in terms of logistics; and also, it has a lower environmental impact in terms of carbon footprint. Even so, the trend of supermarkets and retailers in some countries is to eliminate plastic and replace it with alternatives such as paper or cellulose materials.

But why does paper or cardboard have a better reputation?

Paper or cardboard presents an attractive option for consumers due to their ease of biodegradation. If paper or cardboard escapes from the recycling stream, it biodegrades much faster than plastic packaging. Considering that there are already paper and cardboard solutions available today that match the functionality of equivalent plastic packages, it's understandable why a segment of society prefers this type of material.

Moreover, paper or cardboard can originate from renewable sources when sustainable forest management practices are applied at the source. In contrast, plastic is derived from finite fossil resources, and the only viable method to achieve sustainable production is through recycling.

Giró Cellulose Packaging Range

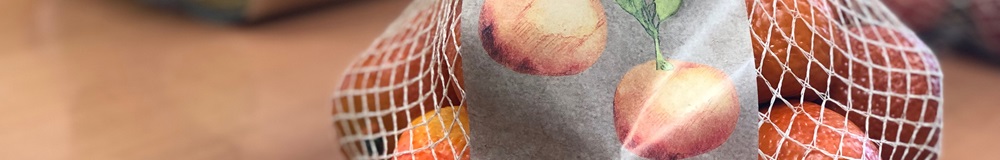

Giró currently offers two types of packaging within the 100% cellulose solution. These packaging variants are distinguished by the technology employed to seal the package. The first type comprises clipped cellulose bags, which involve the closure of a cellulose net with a paper label through a mechanical clipping process.

The second type involves thermal-adhesive cellulose bags. Leveraging this innovative technology (patent pending), Giró provides the option to produce GIRSAC or ULTRABAG Cellulose packaging by bonding the cellulose net with a paper band using an adhesive.

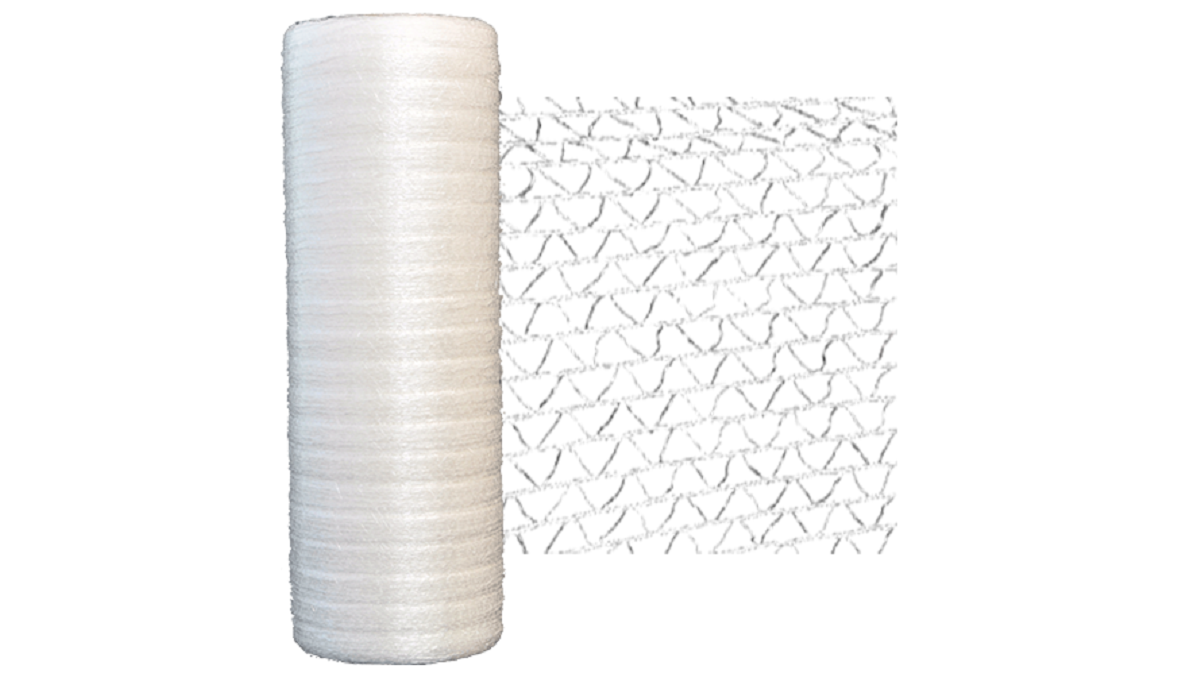

The cellulose netting, commercially known as GIRCEL (“GIRO+CELLULOSE”), is knitted from cellulose fiber threads obtained from wood pulp derived from FSC-certified eucalyptus plantations. This certification guarantees that the raw material is sourced from sustainably managed forests, ensuring GIRCEL netting does not contain materials from unauthorized forests, thereby preventing deforestation.

Compared to the production of other cellulose fibers (such as cotton), the manufacture of GIRCEL is significantly more environmentally responsible. Giró offers a wide range of netting colors, allowing selection based on the content of the packaging.

For both package types—clipped or thermal-adhesive—both the Gircel netting and the Giró film or labels are cellulose-based materials with FSC Certification (AEN-COC-000401). With these innovative solutions, Giró introduces to the market the first packages completely free of plastic and bioplastics (such as PLA or PBAT).

The clipped cellulose packaging

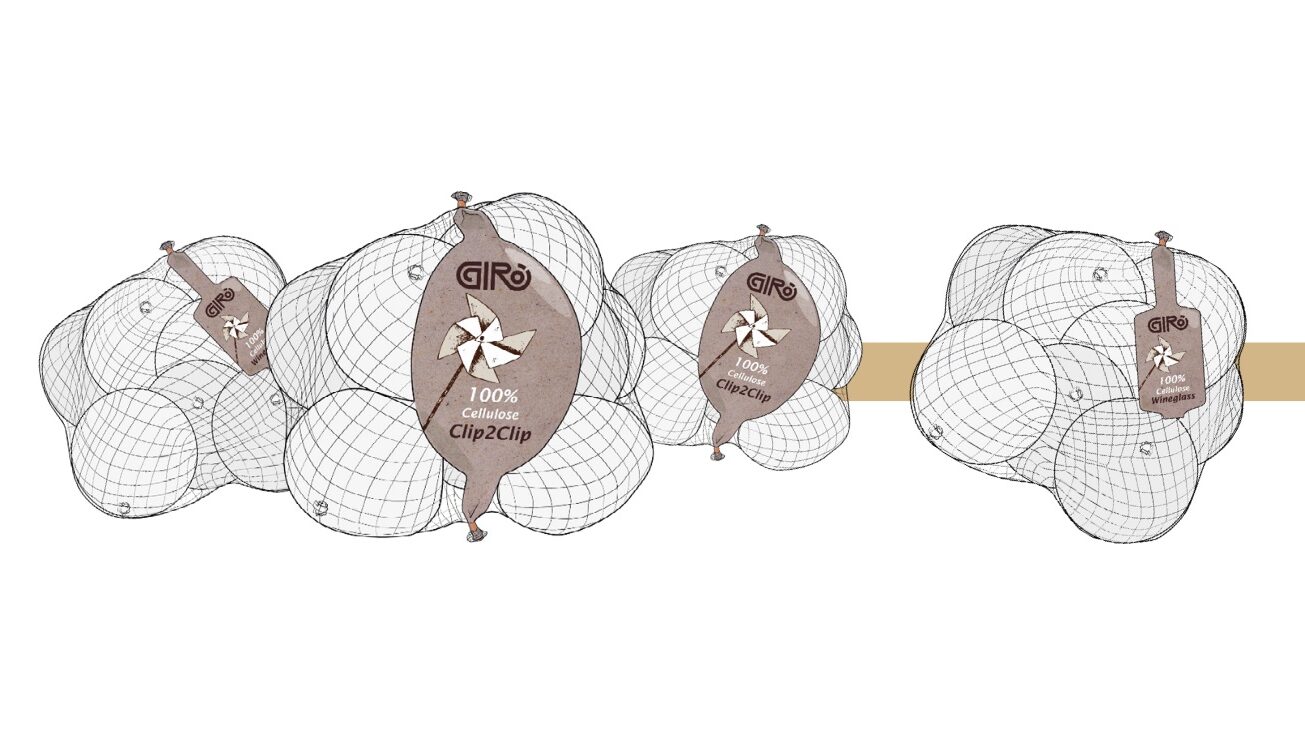

There are two versions of the clipped cellulose package: Wineglass (WG) and Clip2clip (C2C). In the WG packaging, we have a label that is attached by a metal clip at one end of the package. In the C2C, we have a label that is attached by a metal clip at both ends of the bag.

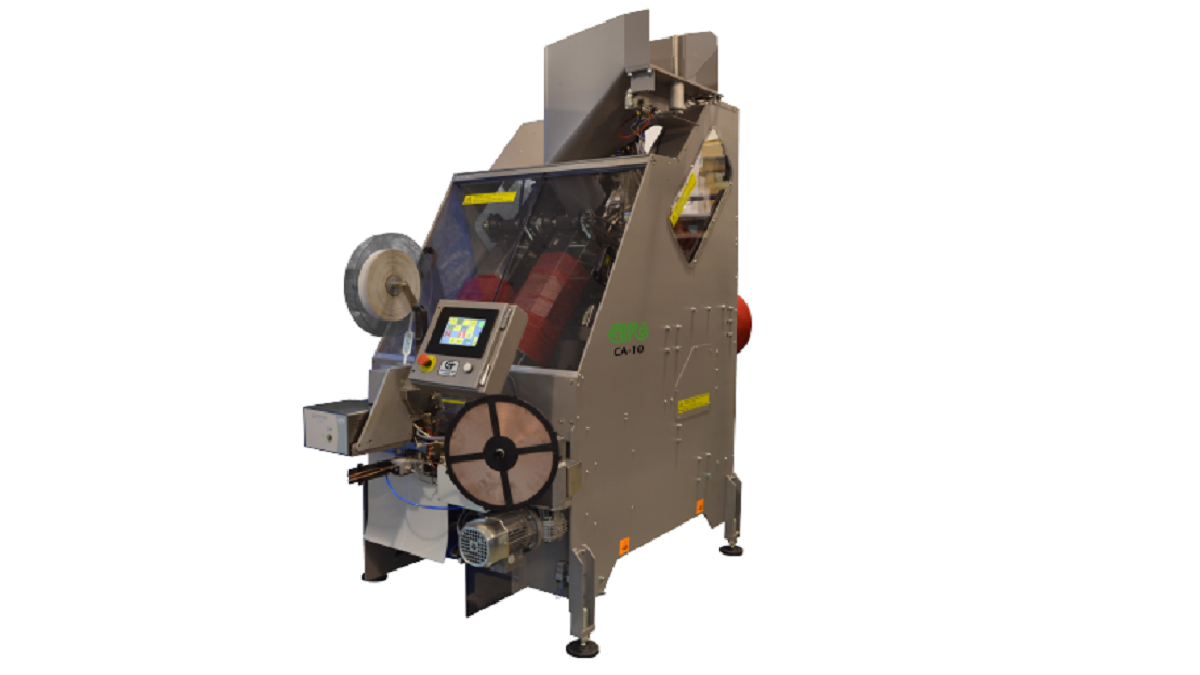

Both WG and C2C cellulosic packages can contain a maximum of 2 kg of weight and can be made with any of our existing clipping machines on the market: CA-9, CA-10, and GH-20. No kit is required for the WG packaging while for the elaboration of the C2C, it is necessary to install a simple additional kit. The machine output when making the cellulose bags remains the same as for plastic materials, up to 35 bags per minute for 1 kg packaging.

Within the different types of cellulose labels, Giró continues to innovate and research new solutions that allow to optimize the amount of material used and make cellulose packaging even more sustainable.

It is for this reason that, at this trade show, Giró presents the new ECO cellulose labels. These labels respond to the need to continue optimizing the amount of material used, reducing the thickness of the labels from 1400 gauge to 560 gauge. This new label aims to be a more sustainable alternative to the current NON-THERMAL cellulose label.

Since this label is thinner and monolayer, we offer it at a competitive price and with an important reduction of the amount of material used in the package. Furthermore, the new ECO cellulose label uses a smoother type of paper allowing a substantial improvement in printing quality, both in the pre-printed design and in the printing of variable data using RIBBON.

It is important to note that this new label is significantly thinner than the previous one and therefore more delicate, so we must ensure the proper maintenance of the CA-9 and CA-10 machines and installation of the necessary kits to obtain a good result on the package.

The Thermal-Adhesive Cellulose Bag

We offer two variations of thermal-adhesive cellulose bags: Girsac and Ultrabag.

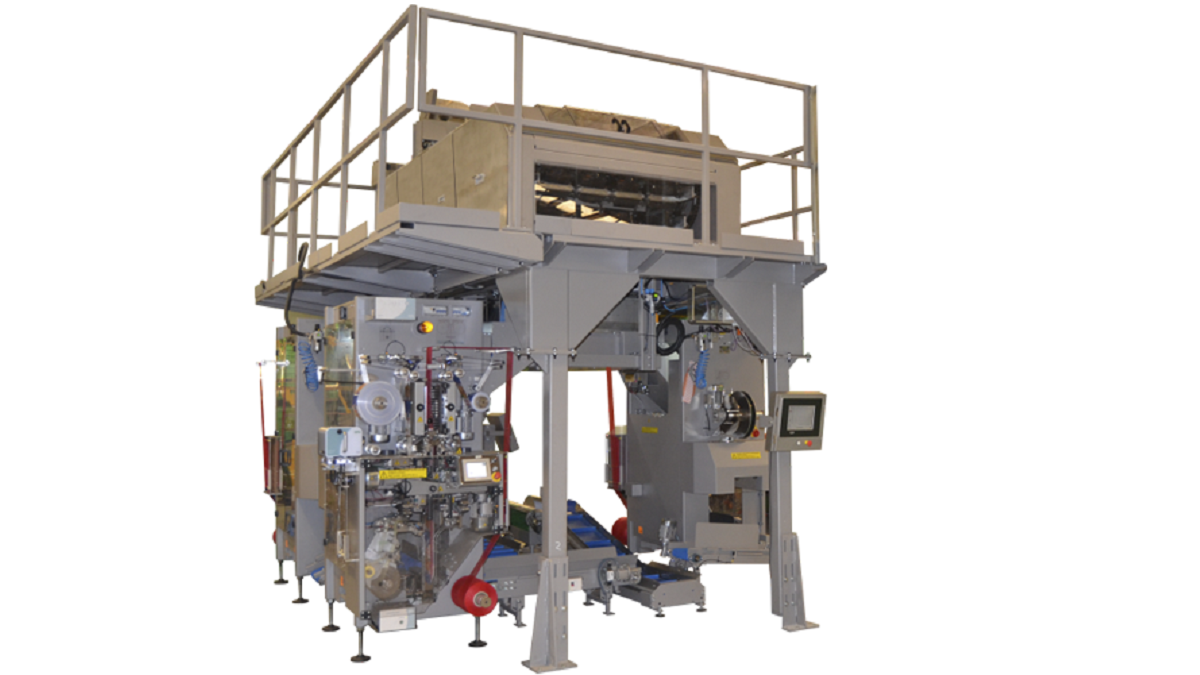

To manufacture both packages, Giró has developed a new technology for sealing the bag using cellulose materials. Previously, the Girbagger machine closed Ultrabag and Girsac plastic bags through thermal welding, where temperature fused the polyethylene net with the plastic film, sealing the bag. For cellulose-based packages, we devised a new system to seal the Gircel net with the paper film.

The inner side of the paper film contains pre-applied adhesive stripes activated by temperature. This facilitates sealing the two films with the net in between, effectively closing the bag. In the case of the Ultra bag package, additional adhesive stripes are vertically applied along the film's length, ensuring complete attachment to the netting, and enhancing the consistency and vertical stability of the bag. Additionally, Giró has developed a die-cutting system to create two openings that make it easier to grip the package.

The maximum weight capacities for these bags are 1.5 kg for Girsac and 2.5 kg for the Ultrabag.

Due to the handling of more delicate materials, the Girbagger's output when producing these bags is slightly lower, reaching up to 30 bags per minute for 1 kg of packaging.

It's important to note that an additional kit needs installation on the GirBagger to manufacture the Girsac and Ultrabag Cellulose bags. Once the kit is installed, adjusting the parameters on the screen enables the machine to process both plastic and cellulose materials.