Conditioning , Packaging

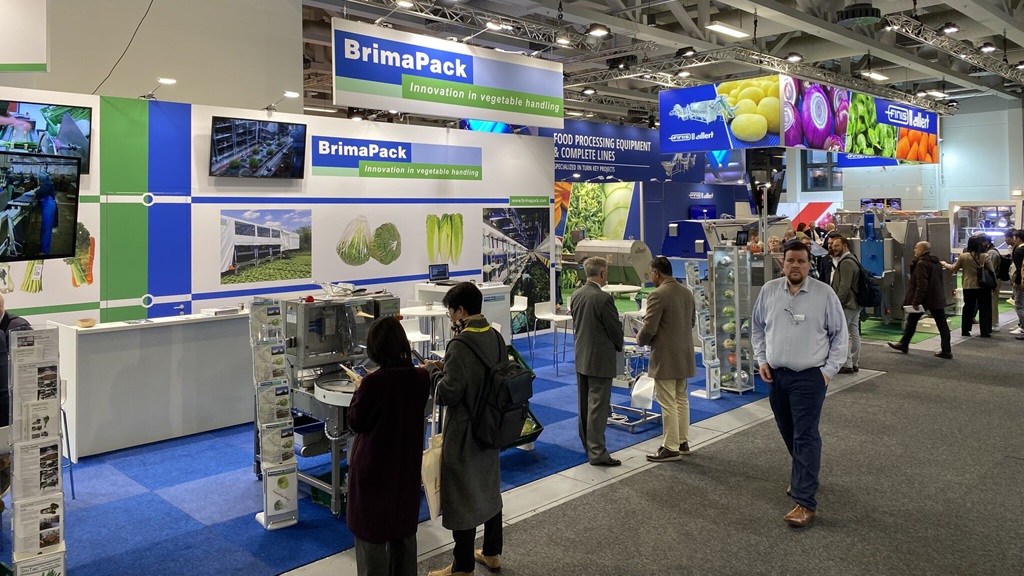

BrimaPack, leading player for handling solutions for Iceberg Lettuce, Broccoli, ?, again in Fruit Logistica

Innovation in vegetable handling recognized through the nomination for the United Fresh Produce Innovation Award 2017 and for the Fruit Logistica Award 2014. The latest developement includes the next generation in transplanting equipment. BrimaPack is currently a leading player in vegetable, and some fruits, handling solutions BrimaPack offers innovative solutions for vegetable handling solutions for Iceberg Lettuce, Broccoli and various other vegetables and fruits. One of them is the the ?NicePack? packing systems giving superior shelf life and lower packing costs compared to other technologies. The new BrimaFilm AF has been exclusively developed to increase the shelf life of broccoli and other

16 January, 2019

Innovation in vegetable handling recognized through the nomination for the United Fresh Produce Innovation Award 2017 and for the Fruit Logistica Award 2014. The latest developement includes the next generation in transplanting equipment. BrimaPack is currently a leading player in vegetable, and some fruits, handling solutions BrimaPack offers innovative solutions for vegetable handling solutions for Iceberg Lettuce, Broccoli, Cauliflower, and various other vegetables and fruits. One of them is the the NicePack packing systems giving superior shelf life and lower packing costs compared to other technologies. The new BrimaFilm AF has been exclusively developed to increase the shelf life of broccoli and other brassicas such as cauliflower and cabbage. The extension of the shelf life is at least 5 8 days (at 17 degrees centigrade). This is reached in a natural way by creating an optimal atmosphere for Broccoli storage and display. Through its focus on supplying System Integrated Solutions, rather than individual machines, BrimaPack offers complete packing solutions for pack house and field packing operations, which saves up to 50% on packaging costs and enhances shelf life and product presentation.BrimaPack has been nominated in the category Best New Packing/Processing Equipment for the United Fresh 2017 Produce Innovation Awards, with the VeTrac e-Drive Planting/Harvesting Rig.VeTrac II 9/7 T 18-row TransplanterBrimaPack has built and delivered a VeTrac II 9/7 T 18-row transplanter. With three, six row Ferraris FastBlock Transplanter modules, attached to the VeTrac e-Drive caterpillar from BrimaPack, the machine can transplant up to 8 meters wide with a maximum capacity of 130.000 Plants/hour. The VeTrac is suitable for transplanting celery, iceberg lettuce and other vegetables.Planting speeds are variable from 500 meters per hour up to 3.500 meters per hour. The Trimble RTK-GPS autopilot is used for automated raster planting. The VeTrac platform can store 12 to 16 pallets during transplanting. It is equipped with unique automated logistics to transport trays to and from the planting section. Workers are protected for heavy wind by windbreaks on the sides and back.BrimaPacks unique e-Drive system is lowering fuel costs and greenhouse gas emissions drastically and is giving you optimal drivability suitable for todays demands and future expectations. The unit has Wireless Remote control for driving, steering, lifting, transplanting and folding.After uncoupling the 18-row planter section and the hydraulic foldable VeTrac, the complete unit can be transported on two semi-trailers.The VeTrac e-Drive is powered by the on-board generator set or directly of the power grid and is even prepared for future battery / solar cell generated power supply. The VeTrac e-Drive has multiple advantages and unique characteristics compared to the conventional harvesters and machine carriers.System Integrated SolutionThe VeTrac e-Drive carrier can be used for various types of applications. Starting at Transplanting, all the way thru to harvesting. Working platforms in de range of 20 x 20 Feet up to 30 x 35 Feet are available. Lifting capacities from 3 to 12 tons, front and rear. The carrier can be equipped with; pre- and post-sorting technologies, labelling/printing, logistics, GPS controlled remote access for service, diagnostics and monitoring, even from your smart phone. The customer specific design, ensures an optimal solution tailored to your specific needs. Pictures1 - VePack200-P2 - 18 row transplanter