Conditioning

UNITEC integrated technology supply chain at Macfrut 2023

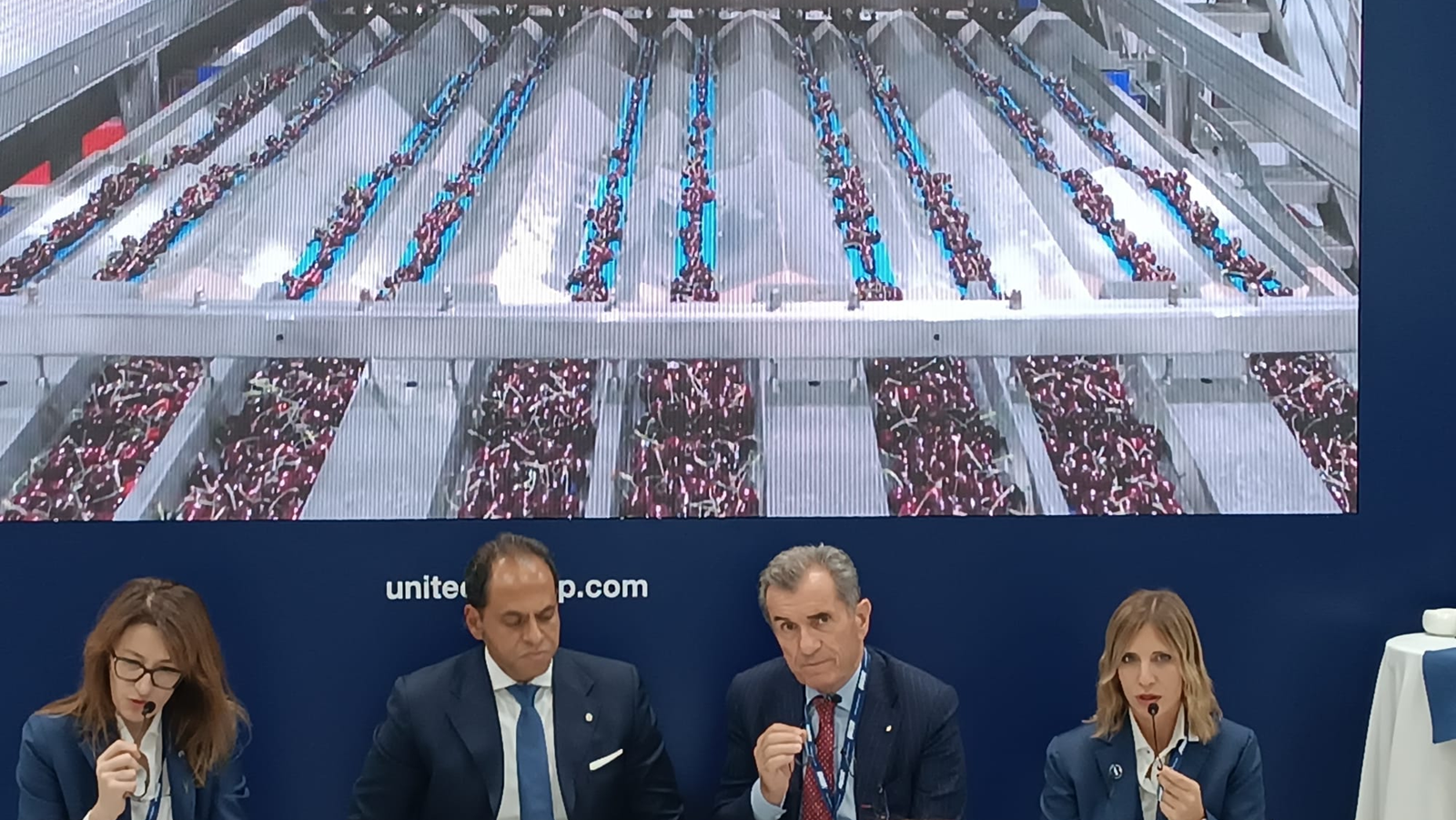

With nearly 100 years of experience, UNITEC is confirmed as the leading company in innovative technological solutions serving the fruit and vegetable supply chain. Based in Lugo (RA), the company develops patented innovations for sorting more than 50 types of fruit, applying the skills acquired across different segments of the supply chain, with an international reach. In fact, UNITEC technological solutions have a place in the field as well as in the warehouse: innovative systems that directly assist producers, such as the motorized harvesting platform with automatic fruit sorting, that respond to the needs of at the different phases of the process, where they select external and internal fruit quality parameters non-destructively, as well as packing and palletizing stages using robotic anthropomorphic solutions.

09 May, 2023

With nearly 100 years of experience, UNITEC is confirmed as the leading company in innovative technological solutions serving the fruit and vegetable supply chain. Based in Lugo (RA), the company develops patented innovations for sorting more than 50 types of fruit, applying the skills acquired across different segments of the supply chain, with an international reach. In fact, UNITEC technological solutions have a place in the field as well as in the warehouse: innovative systems that directly assist producers, such as the motorized harvesting platform with automatic fruit sorting, that respond to the needs of at the different phases of the process, where they select external and internal fruit quality parameters non-destructively, as well as packing and palletizing stages using robotic anthropomorphic solutions. As a result, fruit and vegetable sorting starts from the field with the motorized harvesting platform, which provides real-time information on organoleptic characteristics to the workers in order to correctly harvest fruits and vegetables that are already suitable. As a result of this UNITEC solution, operations in the field can be accelerated, processing over 20,000 fruits per hour, with benefits also reflected in the storage phase. In fact, since the number of products to be sorted is lower, storage and sorting costs can be reduced by approximately 5 to 6 percent. UNITEC projects focus on ensuring that fruits are of consistent quality. In fact, the company - in its Research & Development Center, with more than 150 researchers - develops technological solutions dedicated to each fruit enabling selection of fruit and vegetable products based on a variety of independent parameters, evaluated individually and in a wide range of combinations based on the analysis objective. For example, the Blueberry Vision 3 system integrated in the Unical 222 Berry sorter, allows packing houses to non-destructively inspect the entire surface of each blueberry thanks to sophisticated highresolution cameras. Through this system, it is possible to select fruits based on external quality parameters, such as color and shape defects, in addition to optical size. The UNIQ Blueberry system - a highly reliable solution for the selection of internal quality - completes the package of the blueberry quality selection stage, safeguarding the integrity of each individual fruit The 2023 edition of Macfrut also sees UNITEC involved as a technical partner of the International Blueberry Days event. It is also by supporting this event that, the Group wants to emphasize the importance of technological innovation in fostering the growth of the blueberry market worldwide, as demonstrated by the results achieved by UNITEC technologies so far. This is a market that needs accurate selection of fruit quality, to ensure that they can be shipped over long distances while maintaining suitable characteristics in order to market them in fresh condition at their destination. This must be accomplished by separating fruits that do not meet these criteria at the source. With 20 operating branches located across the five continents, UNITEC is thus able to collect the needs of the industry and innovate in order to meet their demands. It is from the difficulties that have arisen in the business, as well as the economic and health crises of recent years, that UNITEC, through constant research, continues to develop innovative solutions to meet the challenges facing the market. Anthropomorphic technology systems enable UNITEC to provide solutions that help packing houses respond to today's labor shortage problem and automate labor-intensive tasks that are tedious as well as tiresome for operators. Finally, by integrating automated technology solutions for the packing stage as well, UNITEC enables the evolution of the entire process within the warehouse. With UNI FLOW GENTLE PACKER, operators can maximize the efficiency and potential of automatic apple packing, which is accomplished through the continuous and gentle transfer of the fruit within the honeycomb cell cases. On the other hand, UNI INTELLIGENT PACK DATES, a robotic solution for arranging dates in trays so that they all face the same direction, which helps to better organize the space inside the package, is available to operators in the date supply chain. There are many solutions presented by the Group at this edition of Macfrut, where UNITEC with its 100- year history, offers a complete technological chain to address the needs of packing houses worldwide in order to improve processes, from harvesting in the field to robotics. UNITEC, we work for your results.