Unitec Group

Conditioning

UNITEC Unveils 2025 AI and Robotics Roadmap to Future-Proof Fruit Packing Houses

UNITEC's new innovations at Fruit Attraction 2025

In a global market driven by increasingly demanding quality specifications from clients, and which requires urgent solutions to the labor crisis and climate instability, UNITEC's technological excellence is reaffirmed.

From the heart of Romagna, and with a presence in over 65 countries, the company presented its roadmap at Fruit Attraction 2025 with a clear focus: offering latest-generation automation and artificial intelligence to ensure superior quality standards and sustain the profitability of fruit and vegetable packing houses.

Business Vision from Angelo Benedetti, President of UNITEC

Angelo Benedetti, President of UNITEC, emphasized the company's mission, which goes beyond machinery to focus on the complete project, from the field to final palletization. His main objective is to foster consumer loyalty toward fruit produced in Europe (Spain and Italy, in particular) and to improve the profitability of packing houses by ensuring the final consumer always receives a high-quality product.

Benedetti detailed the importance of going beyond natural factors in the face of climatic variability:

"So many technological solutions to support European and global packing houses with the concrete goal of being by their side. To generate 'results' today, nature alone is not enough; technology is also necessary! Only in this way can we guarantee consistent quality levels which, by generating satisfactory responses for consumers, will bring benefits to the entire chain."

Post-harvest Analysis: AI, from 1950 to Vision 4.0, Faces the Future of Sorting

Artificial Intelligence (AI) was the central pillar of UNITEC's presentation. During the interview, Dr. Alicia Namesny, CEO of Postharvest.biz, raised a key question about the impact of Artificial Intelligence on post-harvest innovation. UNITEC responded that the use of AI in sorting is fundamental.

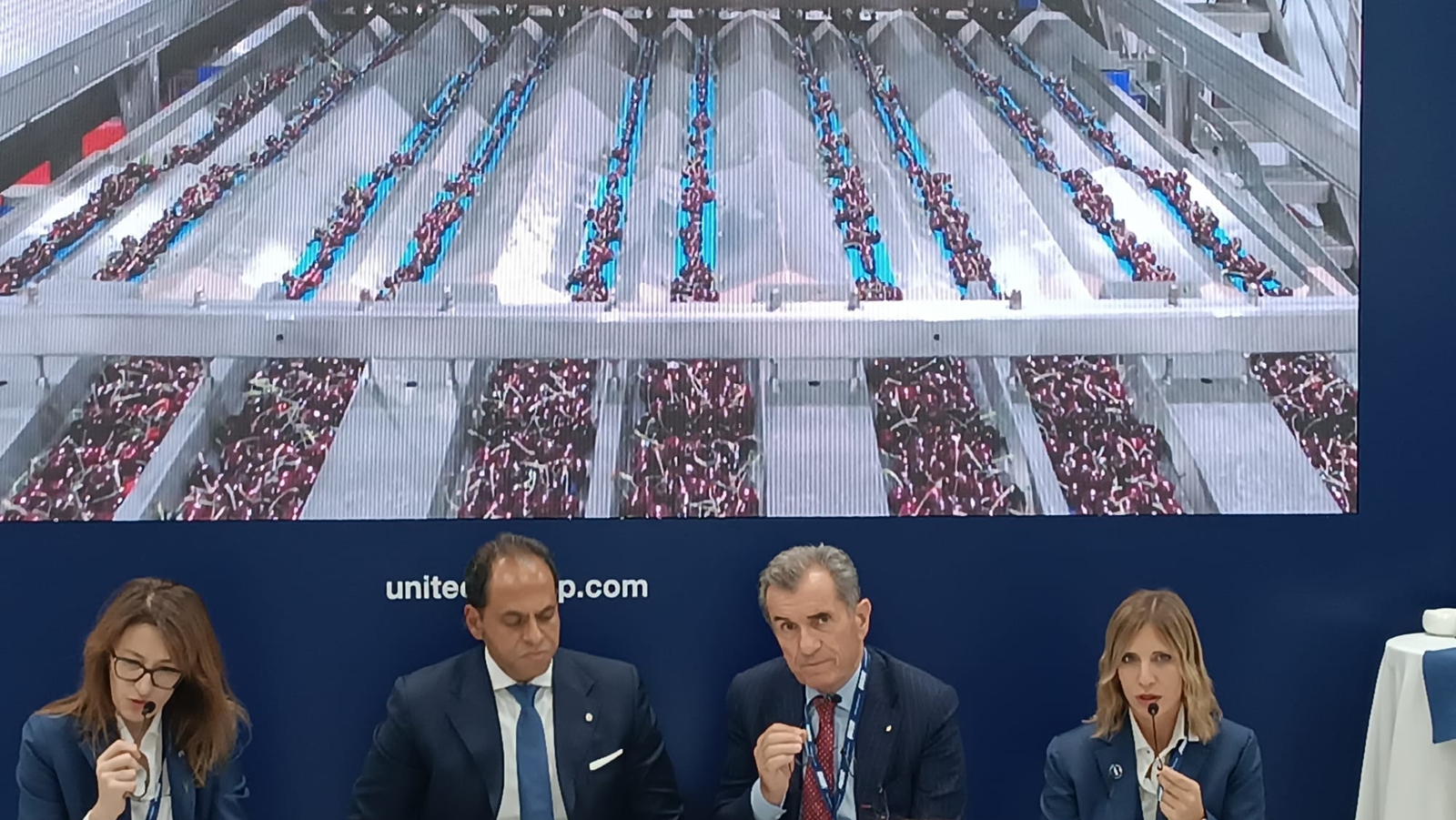

Alicia Namesny, CEO of poscosecha.com and postharvest.biz, in a conversation with Unitec's CEO, Angelo Benedetti, and Nour Abdrabbo, Group Sales Director, in Fruit Attraction 2025

The Vision 4.0 AI technology, the latest evolution of their grading platforms, uses internal algorithms to detect and separate external defects with unprecedented precision.

It was noted that, while UNITEC has used AI since 1950, the high-level models of recent years have allowed for an increasing impact. This AI-powered quality system will continue to professionalize and improve the sorting process, leading to the achievement of more durable and consistent quality.

Among the AI and sorting technologies presented were

- UNIQ: Systems that grade the internal quality (ripeness, sweetness, integrity) of products such as apples, pears, avocados, and dates.

- Plum Vision 4.0 AI: A system integrated into the UNICAL 300 grading machine that applies AI models to plums, classifying shape, size, color, and defects with maximum precision.

- UNICAL 222 for Blueberries: A sampling machine that offers a preview of a batch, helping to control average quality and establish the best process.

Robotics, Value Chain, and Sustainability

One of UNITEC's strengths is its chain-wide vision, which seeks to reduce waste, lower costs, and maximize profitability. The automated lines handle products delicately and quickly, from post-harvest to packaging.

Nour Abdrabbo, Group Sales Director, highlighted the impact of this automation:

"Automation is no longer an option; it is the concrete answer to the increasing difficulty in finding labor. Our solutions improve productivity and efficiency, creating value for the entire chain and ensuring continuity even in the face of climate uncertainties."

The modular automation and robotics solutions for packaging that were highlighted include:

- UNI SMART PACKER (Robot). A UNI ROBOTICS solution designed for packaging clamshells and heat-sealed baskets. It ensures the lid stays closed and protects the container during handling. This system combines efficiency and gentleness, guaranteeing constant production while minimizing personnel usage. Its flexibility allows for quick changeovers between different sizes and formats.

- UNI SMART TRAY FILLER (Robot). An automatic filler that uses the pick-and-place function to pack fruit (such as apples, peaches, and nectarines) into trays or into trays inside a box. The robot is capable of modulating the pick-up and deposit coordinates based on the fruit size and the packaging format being processed, combining efficiency and gentleness.

Future Projections: From Harvest Robotization to Expansion in Peru

UNITEC looks at the complete project, "from the field to final palletization," with two key announcements regarding expansion and innovation:

Advances in Field Harvesting

The company is developing intelligence capable of connecting the packing house directly to the field. The most advanced project focuses on robotized harvesting solutions for apples (and, in the future, peaches, plums, and kiwi), with operations in the field planned to begin in 2026.

Global Expansion

UNITEC announced the opening of a new subsidiary in Peru (with its main warehouse in Trujillo), a strategic move necessary to address the growing demand and logistical challenges in the Latin American market.

The company's claim, "We work for your results," is not just a slogan; it is the force that drives local businesses to become true global players.