Unitec Group

Conditioning

UNITEC, a company that follows the ripe times of fruit

The quality selection and reliability in the precise sorting of each qualitative characteristic are great opportunities to guarantee business today and in the future

UNITEC is an international group specializing in the design and manufacture of innovative solutions for the handling, sorting, quality selection and packing of fruit and vegetables.

What sets it apart on the market is its know-how built up over more than 100 years of history. This wealth of experience has not only made UNITEC a leader in innovation in the fruit and vegetable sector, but has also allowed the company to export the value of Made in Italy to the world's major markets, helping to strengthen Italy's image as a leader in mechatronics, automation, and robotics applied to the agro-industry.

Today, as in the past, UNITEC continues to invest in research, development, and sustainability, offering its customers tailor-made technological solutions capable of meeting the challenges of the global market with efficiency, reliability, and vision.

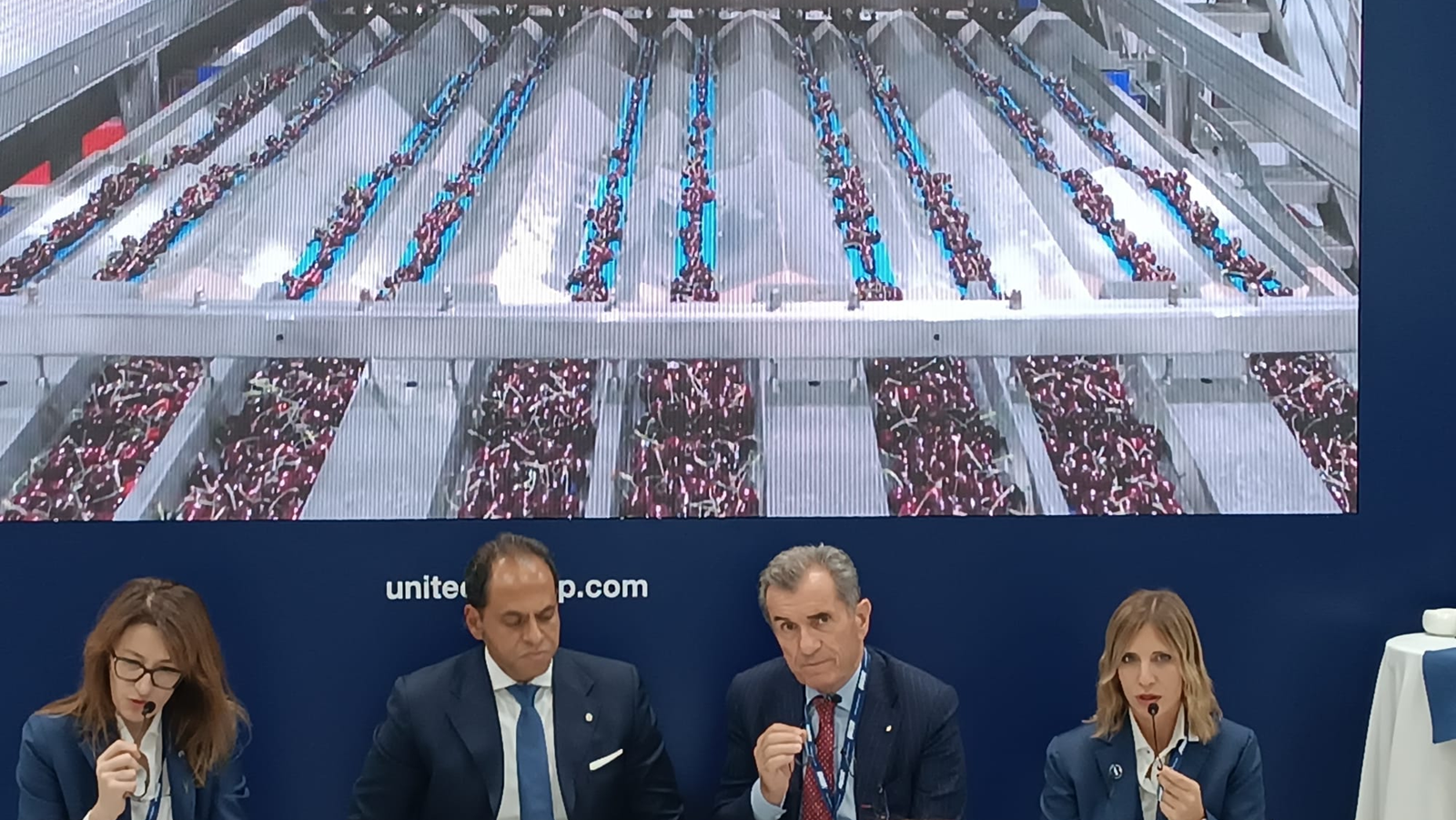

Macfrut 2025 is an opportunity for UNITEC to present its latest technological innovations and, above all, to strengthen its ties with the market. We come from the region of speed engines, and this DNA contributes every day to work with an innovative boost with a very clear mission: to provide concrete solutions to the global fruit and vegetable industry, helping it to be increasingly competitive, both in terms of distribution channels and in surprising consumers with products that are always in line with their taste expectations based on the needs of different markets, including international ones.

Ours is an “Italian marketing”, based on listening to the customer, designing customized and service solutions that are close to each customer: technology without people and without reliability does not make the market grow.

Thanks to patented technologies customized for each stage of the production process, UNITEC improves the efficiency and profitability of thousands of packing houses in over 65 countries around the world. Our solutions adapt to all types of fruit and vegetables, responding to the challenges of a constantly evolving market.

Every day we innovate, simplify, and optimize. Because behind every piece of fruit, there is a piece of technology that makes the difference. Numbers that speak for themselves: over 400 billion pieces of fruit sorted each year by UNITEC technologies: approximately 50 pieces of fruit per year for every person in the world. On average, 12% of sorted fruit does not meet the fresh market standards. Thanks to our technologies (UNITEC and Unisorting brands), these fruits can be used for other purposes, reducing waste. 48 billion fruits revalued every year.

With our patented Cherry Vision solutions, we prevent the waste of approximately 20 billion cherries every year, across 5 continents. That is twice the number of cherries exported by the United States in a year. Every year, we prevent the waste of 19 billion blueberries: the equivalent of 5,000 full containers. We reduce the waste of about 2 billion apples per year: with the apples “saved” from food waste, we could circle the Earth four times.

All UNITEC solutions are entirely made in Italy and are developed to provide continuous solutions for the entire fruit and vegetable handling cycle: from mechanical design to the production of advanced systems of automation, robotics, traceability, and internal and external quality selection, through high-definition vision, with the use of AI in every sorting process.

Pioneers of quality: we were the first in the industry to obtain certifications for: quality, occupational safety, and environmental management.

Technology that looks inside

The exclusive UNI TRACER software package, entirely designed by UNITEC, allows you to record and manage the traceability of different batches throughout the entire process. UNITEC installations equipped with the UNIQ and VISION systems allow for the internal and external quality selection with high reliability, fully safeguarding the integrity of each fruit. A concrete response to the ever-growing need of final consumers to combine the “beautiful” with the “good”.

By the side of the company at every stage

UNITEC technology takes care of the fruit from post-harvest to palletization through the action of various machines with combined and sequential technology. From the crates arriving from the fields to the feeding of the lines with extremely gentle processes to preserve the quality of the fruit, with total traceability of the entire process. UNITEC solutions are 100% Made in Italy, manufactured in-house and they cover the entire fruit and vegetable handling cycle: from project definition to the manufacture of mechatronic and electronic components, software, automation systems, robotics, traceability and external and internal quality selection, with high-definition vision systems.

The UNITEC Group is organized into operating units to closely monitor all the main stages of the production chain, right through the after-sales phase, with a professional and efficient after-sales service. Our proximity to our customers translates into structured support with a network of 20 operating headquarters in some of the most important countries in the fruit and vegetable sector (Washington, California and Oregon in the US, France, Spain, Chile, Argentina, South Africa, Turkey, Australia and Canada) and a commercial structure that allows the UNITEC Group to connect with the individual needs of Customers in the more than 65 countries in which it works. We stand by the side of our customers as a technological partner capable of helping them improve their business, both now and in the future:

We Work for your results!

UNITEC at Macfrut 2025: Focus on Pianeta Rosso and Blueberry Area

Innovative technologies for the sorting of oranges, tomatoes and cherry tomatoes

At Macfrut 2025, UNITEC will present its most advanced solutions for the sorting of oranges, tomatoes, and cherry tomatoes, with technologies designed to meet the needs of large-scale retail chains and, above all, the expectations of final consumers.

The event will take place on May 7 at 2:30 p.m.

Pianeta Rosso – Hall D1. A meeting dedicated to innovation, where we will explore how our technologies can help enhance the quality of fruit and vegetables.

Throughout the fair, there will be an interactive test area dedicated to tomatoes at the UNITEC stand: an opportunity to involve visitors in assessing public preferences in relation to different Brix degrees, a key parameter for defining sweetness and taste perception.

The innovation of UNITEC never stops. Even in the blueberry sector, UNITEC has continued to incessantly innovate every day, to provide concrete answers to packing houses around the world.

Indeed, at Macfrut the UNITEC group, also present in the Berry Area as a PARTNER, will present its external quality selection system and its taste selection system, made possible today by UNIQ Blueberry, entirely designed and developed in-house. We invite you to attend the Berry Conference tomorrow, May 7, at 3:30 p.m.

UNITEC will present some of its technologies at its stand 075 / HALL B1

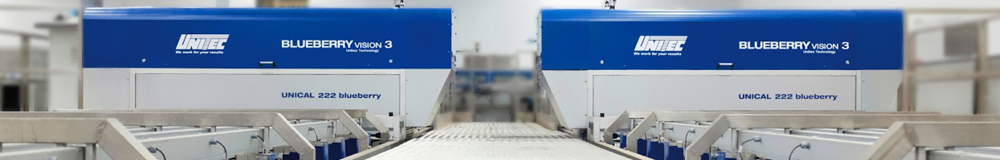

UNICAL 222 BLUEBERRY sampling machine

UNICAL 222 blueberries is now available with a new design, in a single-lane version, as a sampling machine. It offers a preview of a batch of product, it helps to check the average quality of the batch from different producers and, consequently, to determine how to handle the fruit.

UNI SMART PACKER - Robot for clamshell and punnet packing

UNI ROBOTICS brand of UNITEC introduces an innovative solution for packing, a phase in which the use of robotics is becoming increasingly common. Designed for clamshells and heat-sealed punnets, UNI SMART PACKER ensures that the lid remains closed and minimizes the use of personnel in repetitive and labor-intensive tasks, while ensuring consistent production. This system combines efficiency and gentleness, protecting the package during handling. Furthermore, its flexibility allows for quick changes between formats and adaptation to different sizes of clamshells and heat-sealed punnets.

UNIQ UNITEC and UNISORTING solutions for internal quality selection of individual fruits

There are many new developments in internal quality selection systems using Artificial Intelligence, developed entirely by the company's R&D department and dedicated to specific fruits of the UNIQ range, presented at MACFRUT (UNIQ Kiwi, UNIQ Apples, UNIQ Peach, UNIQ Plum, UNIQ Blueberry, UNIQ Cherry, UNIQ Orange, UNIQ Apricot, UNIQ Melon, UNIQ Pomegranate, UNIQ Cherry Tomato, UNIQ Pears, UNIQ Avocados, UNIQ Onions, UNIQ Dates, etc.).

UNI SMART TRAY FILLER

An automatic filler that allows packing different varieties of fruit, such as apples, peaches, nectarines, and apples to be packaged in trays or in trays inside crates. The fruit is picked and placed in the trays by an innovative robot with a pick and place function, which can adjust the picking/placing coordinates based on the size and format of the package being handled.

UNICAL 244 DATES

Electronic sorter designed for handling small-sized products such as plums, cherry tomatoes, jujubes, olives, radishes, chestnuts, walnuts, and dates.

Key advantages:

- Significant cost reduction compared to manual handling;

- Possibility of using unskilled labor;

- Objective increase in handling efficiency;

- High performance thanks to latest-generation, easy-to-use software.

Foscus on oranges and tomatoes, our presence at Pianeta Rosso when the characteristics of fruit become a brand for the market through UNITEC-certified technology

Red oranges

Consistent quality in line with the promise made to the customer should be a prerequisite for quality; however, in the fruit and vegetable sector, this cornerstone of a valuable relationship along the supply chain is often blatantly disregarded. Take red oranges, for example, whose pulp pigmentation varies from a slight streak to a uniform red color, even within the same batch of product. Unfortunately, as revealed by Agroter's Monitor Ortofrutta, based on a survey of 3,000 people, 76% of respondents believe that these are two different types of oranges and, therefore, when they find them in the same package, they think that different products have been mixed together, which causes deep dissatisfaction. Thanks to UNIQ ORANGE, the sorter for internal quality selection of UNITEC, the problem can be managed by separating products that do not reach a defined color threshold from those that do. Thus, in a 10-week test conducted on 40 stores in a distribution chain in Northern Italy, the product selected with UNIQ ORANGE with over 80% coloration went from 0 to 33% of total red orange sales, despite its average price during the period being $2.91 per kg compared to $1.59 per kg for other red oranges. Even more significant is the fact that 66% of those who purchased the product in the first three weeks of the test continued to buy it until the end.

Tomatoes

Similarly, for tomatoes, sensory tests show contrasting results even for the same product in relation to its low absolute sugar content and high acidity. If we add the great variability that often accompanies production throughout the season as a result of changes in influential parameters, the result is deep dissatisfaction among consumers with what they buy and eat, as they tend to remember negative experiences more. Today, however, thanks to the technology of UNITEC, it is possible to address this critical issue by measuring the internal quality of individual tomatoes. Therefore, although tomatoes are complex to understand and interpret, it is possible to work profitably on quality during the selection phase. In this regard, at the UNITEC stand at Macfrut, a comparative test will be carried out with two types of tomatoes selected not only on the basis of external quality parameters but also on the Brix degree, so as to have products in the same tasting sample with similar taste characteristics, in order to measure how much the variability in the quality characteristics of the product from the same batch influences consumer judgment on a small product such as tomatoes.