News

PAF, a novel technique to reduce rotted fruits and residues

The efficacy of PAF, Plasma-Activated Fog, against fungal rot was assessed on table grapes and strawberries, revealing a reduction in the percentage of rotted fruits exposed to 10 min of treatment; PAF treatments also reduced pesticide residues on grape bunches and strawberry fruit

During storage, fruits and vegetables are susceptible to the pathogens responsible for postharvest decay.

Various tools are available to manage these issues, but not all are environmentally sustainable. Low-temperature plasma (LTP) has garnered significant attention among the most promising and eco-friendly solutions.

LTP can be applied directly or indirectly, offering versatile applications.

One notable indirect application is the utilization of plasma-activated water (PAW). In this study, we investigated the efficacy of an aerosol made by droplets of water nebulized by the effluent gases of a plasma discharge as a delivery method of PAW to substrates.

We named this novel application, reported for the first time, plasma-activated fog (PAF).

In this work, it was tested as a new alternative technology for fruit decontamination against postharvest fungal pathogens and pesticide residues.

Results

PAF was generated via volume dielectric barrier discharge (VDBD) in a jet-like configuration and was applied to evaluate the in vitro effects on the conidial germination of major fungal postharvest pathogens, such as Alternaria alternata, Aspergillus carbonarius, Botrytis cinerea, Cladosporium sp., Monilinia fructicola, Penicillium italicum, Penicillium expansum and Rhizopus sp.

Differences in fungal sensitivity to PAF were recorded, with A. alternata showing the lowest sensitivity to treatments.

For most species, complete spore inhibition was obtained after 3–5 min of exposure.

The efficacy of PAF against fungal rot was assessed on table grapes and strawberries, revealing a reduction in the percentage of rotted fruits exposed to 10 min of treatment, ranging from 45 to 80% on table grapes and from 52 to 74% on strawberries.

PAF treatments also reduced pesticide residues on grape bunches and strawberry fruits, with various results depending on the active ingredient, with reductions of up to 96% for abamectin among insecticides and acaricides, and up to 38% for the fungicide fenhexamid.

Conclusions

The results obtained in the present work have the potential to refine and optimize PAF treatment conditions for the antimicrobial decontamination of plant products.

Introduction

Postharvest pathogens are responsible for significant economic losses every year, leading to both qualitative and quantitative losses in a wide range of fruits and vegetables, and can be responsible for human health risks due to the production of mycotoxins [1, 2].

Strawberry (Fragaria × ananassa Duch.) and table grape (Vitis vinifera L.) are highly susceptible to postharvest decay caused by a range of pathogenic fungi.

The long-term preservation of fresh grapes requires appropriate methods of cold storage and chemical treatment [1, 3, 4].

Storage of strawberries is a challenge, as harvested fruits are often affected by mechanical damage and fungal rot, which can rapidly reduce fruit quality [5].

Strawberry and grape cultivation

Strawberry production is approximately 10 million tons worth more than 22 billion USD from approximately 400,000 ha worldwide [6]. In Italy, strawberries cover 4,200 ha in 2025, according to CSO Italy [7], with farming that is mainly concentrated in southern Italy (i.e. Campania and Basilicata regions).

Grape cultivation is widespread throughout the world [8], and the Apulia region is one of the most important areas in Italy in terms of grape production. In 2024, the region produced 592.600 tons over an area of 25,455 ha, compared with 1,041.8 tons and 47,514 ha for the whole country [9].

Goals of, and innovative technologies

The adoption of innovative technologies that prioritize sustainability and human safety becomes imperative to mitigate yield losses resulting from plant diseases, both in the field and postharvest.

Various tools are available to manage postharvest losses, and among them, the excessive use of chemicals poses significant risks for the environment and human health because of the presence of chemical residues in food [10, 11].

The European Commission has set a concrete strategic plan aimed at reducing the use of synthetic pesticides and associated risks, with the implementation of the Farm to Fork strategy aimed at reducing pesticide usage by 50% by 2030.

Additionally, the use of plant protection products must not only comply with current European regulations but also be influenced by the marketing strategies of mass market retailers, which often impose limits below the legal thresholds [12, 13].

Plasma applications

In recent years, interest in low-temperature plasma (LTP) applications has increased in the agriculture sector and food industry [14] because of their innovative approach, which is linked to eco-friendly sustainability [15] and the absence of chemical residues released by treatments in the environment and products [16].

Many recent papers have proven the effectiveness of direct [17,18,19] and indirect methods [20,21,22,23] for applying LTP. Among indirect plasma applications, plasma-activated water (PAW) has attracted increasing interest from the scientific community for a variety of applications, such as plant irrigation, which promotes growth and defense responses [20] and decontamination of agricultural and food products from microbial pathogens [24, 25].

PAW production involves the exposure of a water reservoir to a plasma discharge. Reactive oxygen and nitrogen species (RONS) that are produced by plasma are dissolved in water, where their chemistry can advance to stable, long-lived species (i.e. H2O2, NO2− and NO3−) that can be conveyed to a substrate.

In the case of decontamination of food products, the antimicrobial effect of PAW has been widely demonstrated, highlighting the combined role of low pH and high contents of reactive oxygen and nitrogen species (mainly NO2, H2O2, and reaction intermediates) [25]; however, no clear consensus on the exact mode of action has been reached.

The shortest possible latency between PAW production and its application allows the efficacy of treatments to be maximized.

LTP treatment was also shown to induce the degradation of pesticide residues [26,27,28,29].

A novel method for PAW production and application

In this work, we propose a novel method for PAW production and application to products that involve the nebulization of PAW at the same time as its production.

Other studies reported the advantages of using a finely dispersed aerosol as a delivery medium of PAW or other plasma-activated media to the target substrate.

Different methods for producing plasma-activated aerosols have been tested, but these methods involve nebulizing the previously produced PAW [30,31,32,33] or generating an aerosol starting from a plasma-activated hydrogen peroxide [34,35,36,37]. For example, de Oliveira Mallia et al. reported the antimicrobial efficacy of aerosols produced by surface acoustic waves and subsequently activated by using them as feed gas in a plasma reactor [23].

Plasma-activated fog, PAF

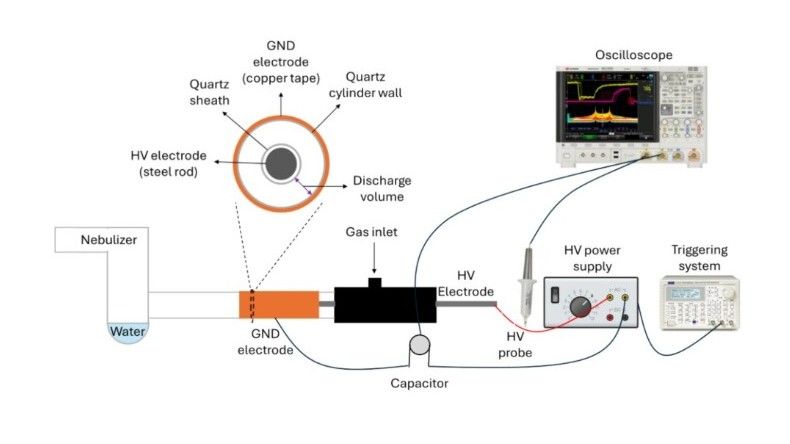

In the present work, effluent gas from a cylindrical coaxial volume dielectric barrier discharge (VDBD) reactor was used to nebulize double distilled water, obtaining a finely dispersed fog (droplet diameter < 5 μm).

We named this novel technology plasma-activated fog (PAF) and investigated whether it allows the inhibition of fungal pathogens and the degradation of pesticide residues on the fruit surface.

The key advantage of this approach with respect to prior works [30,31,32,33,34,35,36,37] is that a larger water surface interacts with plasma species, implying higher production of RONS delivered by aerosols.

Moreover, the absence of humidity in the discharge chamber enables improved chemical stability of the plasma effluents, whereas a greater number of micrometric droplets enhances delivery and efficacy.

Aim of the research

The aim of this study was to assess PAF as a decontamination tool for microbial and chemical contaminants on fruits.

To this end, we investigated its antimicrobial potential against major postharvest fungal pathogens both in vitro and in vivo, its effect on fruit spoilage in strawberries and table grapes, and its ability to reduce various pesticide residues in fruits.

The figure is Fig. 1 of the original paper, Schematic representation of the plasma reactor used to produce plasma-activated fog (PAF). The insert presents the front sight of the reactor

Source

Aceto, D., Rotondo, P.R., Laera, S. et al. Application of plasma-activated fog (PAF) in postharvest treatments to reduce spoilage by fungal pathogens and pesticide residues in fruits.

Chem. Biol. Technol. Agric. 12, 151 (2025).

https://doi.org/10.1186/s40538-025-00865-0