Wyma Solutions

Processing

Industrial-scale processing of vegetables

Wyma develops integrated high-capacity vegetable processing lines that combine intake, washing, grading and cooling, reducing water consumption, labour requirements and product damage

As vegetable processing volumes continue to grow worldwide, packhouses need lines that can work on a large scale without compromising product quality or driving up water use and labour costs. Wyma develops complete postharvest lines for crops such as potatoes, carrots, onions, parsnips and beetroot, designed to combine high throughput, gentle handling and long service life.

These solutions are based on modules built in 304 stainless steel and equipped with smart automation, allowing operators to adjust flow rates, retention times and washing intensity according to the product and the capacity of each facility.

Complete lines for high throughputs

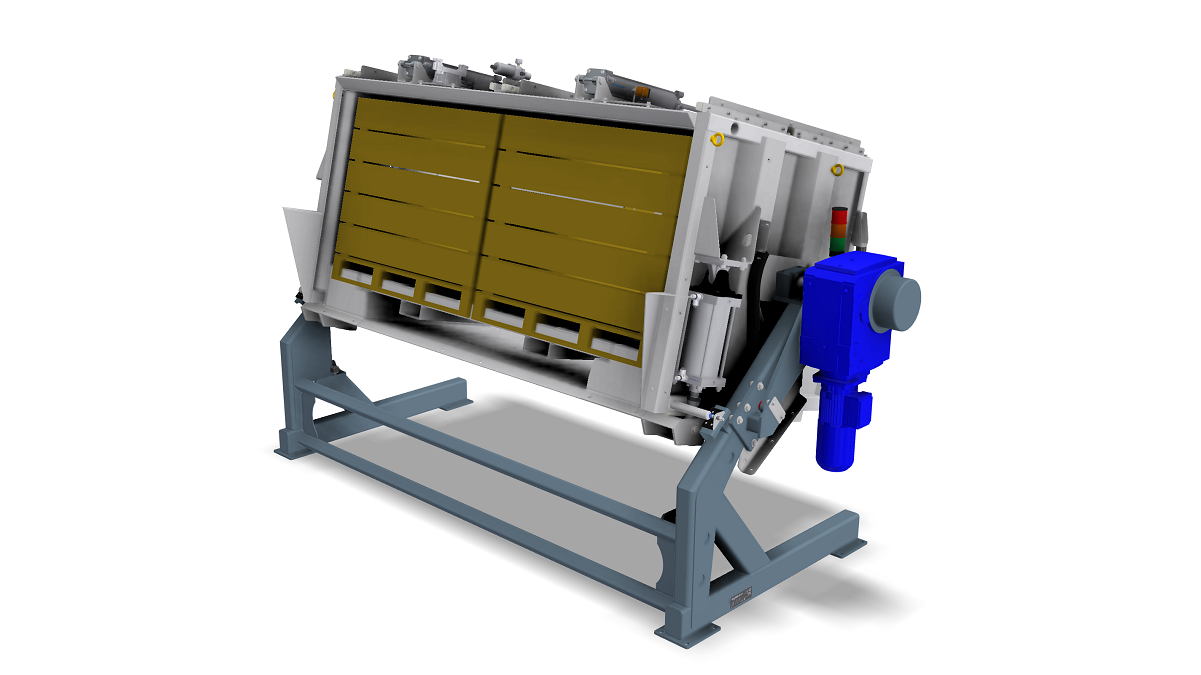

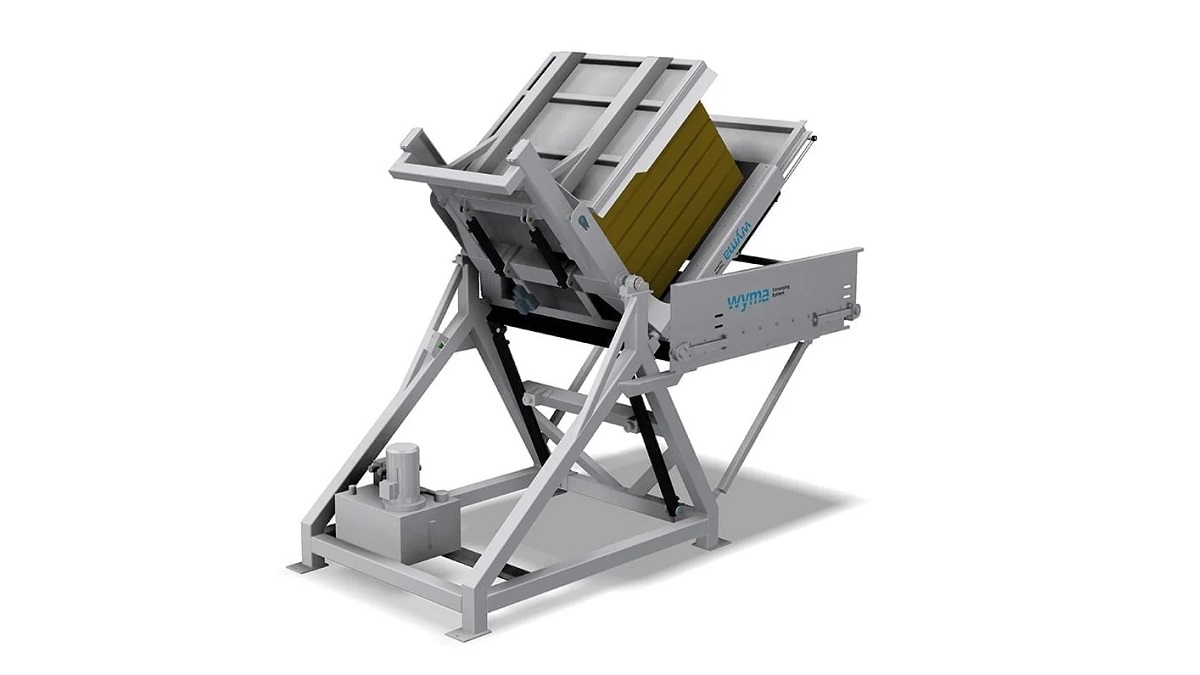

At the start of the line, the Mega-Tip rotary bin tipper unloads bins of up to 5 tonnes, transferring the product smoothly and in a controlled way to the rest of the system and reducing product loss and spillage. Next, the Wyma C-Series wet hopper combines soaking, pre-cleaning, buffer storage and flow regulation in a single unit, with versions capable of handling up to 65 t/h.

Washing is carried out by drum washers that remove soil, stones and debris from root vegetables, with adjustable speed and water levels to adapt washing intensity to each crop. For customers looking for a more refined presentation, especially in carrots, Wyma offers high-capacity polishing solutions capable of handling up to 20 t/h and achieving uniform, glossy finishes.

Grading by size can combine perforated screen systems and lift roller sizers, which separate the product into different diameter grades at high throughputs while maintaining gentle handling. Transfer between machines is performed by Octal series conveyors and elevators and, where it is important to reduce mechanical handling, by flumes that use a controlled water flow.

In the final stages, hydro-coolers rapidly reduce product temperature to preserve freshness and extend shelf life, with configurations for both bulk product and full bins, using immersion or shower cooling.

Automation and centralised control

Wyma lines incorporate automation systems with intuitive HMI panels, variable speed drives and real-time monitoring, allowing each section of the line to be adjusted to intake, washing and grading conditions. The Wyma SmartLine™ platform centralises control of multiple machines and makes it easier to diagnose issues and optimise the overall performance of the installation.

Reliability, maintenance and global support

The systems are designed for long service life and simple maintenance, with modular components, centralised lubrication and accessible service points. With offices and partners in Europe, Australasia, the Americas and Asia, Wyma combines global experience with local knowledge to help vegetable processors design efficient lines that are gentle on the product and tailored to the needs of each crop.