Wyma Solutions

Processing

Modernization of Lundstad Grønt's carrot processing line with Wyma technology

The line upgrade enables more uniform processing, lower water and energy consumption, and greater operational reliability in carrot handling

Lundstad Grønt, a Norwegian carrot producer based in Kolbu (Østre Toten, Norway), has completely revamped its processing line with the aim of improving the capacity, efficiency, and sustainability of its operations. The project, carried out in collaboration with Wyma, has increased polishing capacity by 30% and reduced water consumption by around 75%.

Line optimization to improve performance and efficiency

The project began as an upgrade of the Newtec Celox optical sorter, but a broader assessment revealed that the main limitations were in the washing and handling line. The existing equipment could not meet the company's growing needs for productivity, sustainability, and reliability.

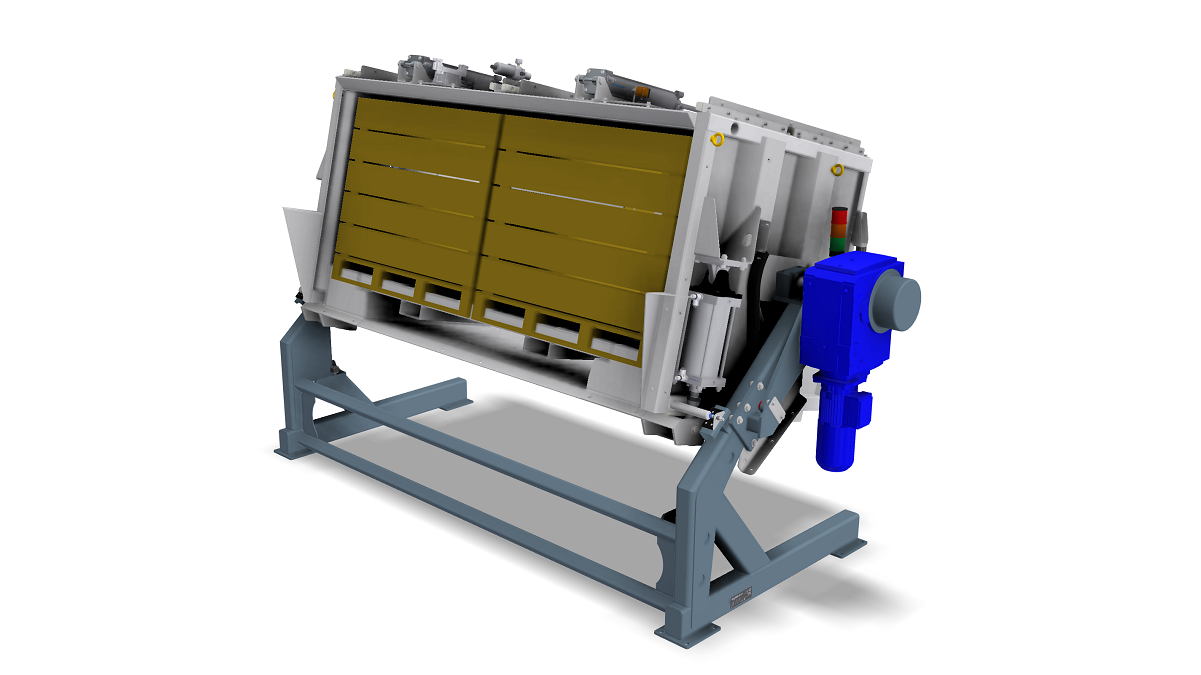

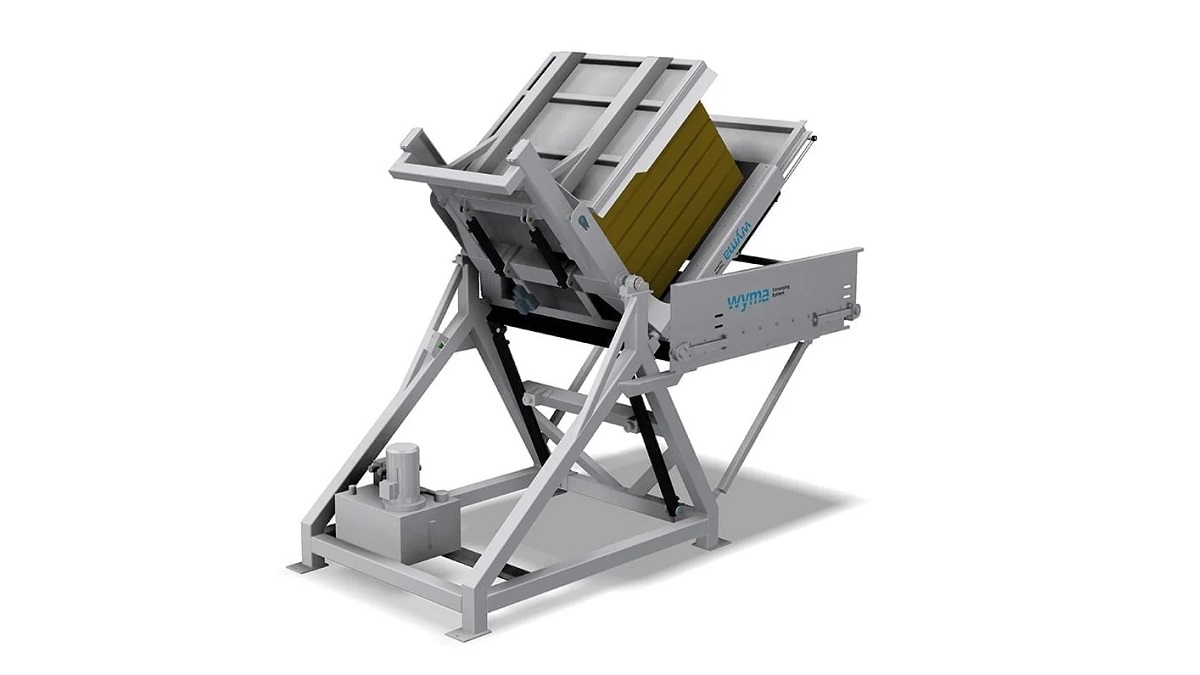

Taking a consultative approach, Wyma and Lundstad Grønt redesigned the facility to create a more flexible and efficient 10-ton per hour processing line with lower water, energy, and labor consumption. The equipment incorporated includes a C-series wet hopper, a hedgehog cap remover, a cyclone discarder, Octal conveyors, channel systems, a barrel washer, and a Vege V2B polisher, capable of soaking, washing, polishing, sorting, storing, and packaging with different combinations according to needs.

The collaboration between the two companies is not new: years ago, Lundstad Grønt had already purchased a smaller capacity Wyma Vege polisher, whose performance reinforced the confidence that has now enabled the complete renovation of the line.

Improvements achieved and next steps

Since installation, the system has achieved significant improvements:

- 30% increase in polishing capacity, replacing two old machines with a single Vege 3016 V2B polisher.

- Approximately 75% reduction in water consumption, with associated energy savings.

- Up to 25% improvement in the accuracy of the Celox optical sorter, thanks to the more uniform product presentation achieved with the Wyma flat brush machine.

- Increased operational availability and reduced operating hours, supported by more efficient management of storage hoppers.

The result is a washing line that is ready for the future, capable of processing a higher volume of carrots more uniformly and with less use of resources. Following the success of the project, Lundstad Grønt is already considering new investments with Wyma, including a Roto-Cut peeling line and a new packaging line.