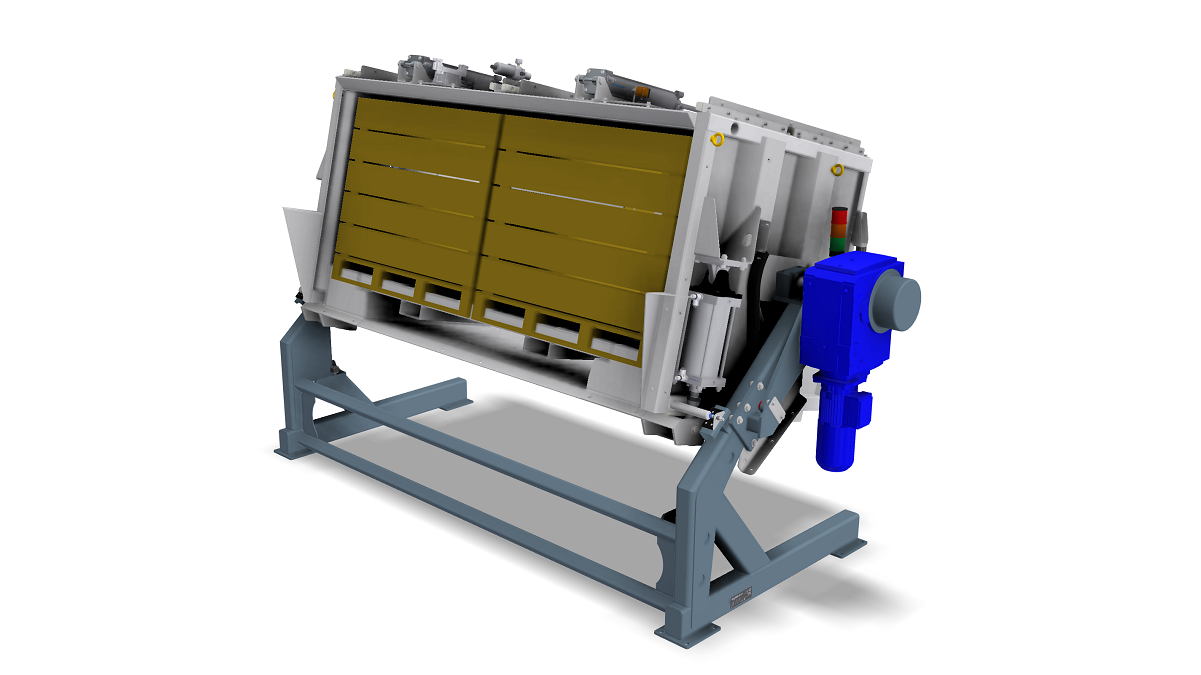

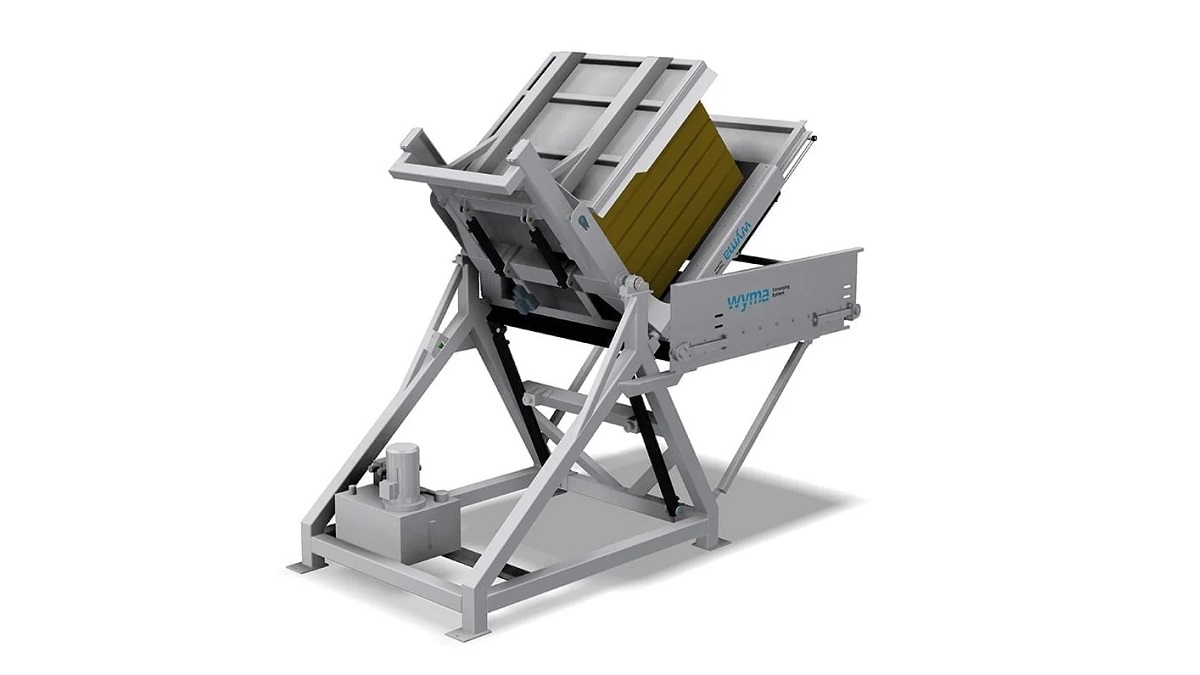

Wyma Solutions

Conditioning

How to plan ahead for maintenance during the holiday rush

As production ramps up before Christmas, now is the ideal time to monitor equipment performance and plan for any post-season service needs

For many processors in Europe and the UK, the weeks leading up to Christmas are the busiest of the year. With production operating at a high and sustained pace to build up stock ahead of the holidays, teams work longer hours and under greater pressure than usual. This scenario often brings to light the first signs of wear and tear, which are often imperceptible during quieter periods.

Although December is not exactly a quiet time for maintenance, it is an ideal time to observe how the processing line responds under continuous use. Even minimal variations in performance (noise, vibration, loss of capacity, or an increased need for operator adjustments) can be early signs of components that will require attention when activity slows down.

Why this period is important

High demand production does not mean that machinery is working beyond its intended limits, but it does accelerate wear and tear in critical areas such as bearings, rollers, belts, washing systems, and automation components. Identifying these issues now can prevent unexpected downtime once operations ramp up again in early 2026.

By recognizing changes in performance during this peak period, processors can plan timely and efficient maintenance work after the holiday season, rather than reacting to failures at the start of the next season.

Plan ahead for post-season maintenance

Technician availability across Europe is limited at the start of the year, so those who plan their postseason service now will have more options to secure the dates they need.

Wyma's aftermarket team can assist you with:

- End-of-year equipment condition assessments to detect emerging issues.

- Advance booking of postseason services to secure preferred time slots.

- Inspection and replacement of critical components such as bearings, belts, sensors, and motors.

- Performance optimization through calibration and fine tuning.

- Customized service packages and maintenance plans tailored to your line, crop type, and level of use.

Prepare your farm for a good start in 2026

The end-of-year production period provides valuable insight into how your equipment performs under pressure. By noting performance trends, recording any issues, and planning maintenance tasks in advance, you can protect uptime, extend the life of your equipment, and start the new season with confidence.

Wyma's local service teams in Europe and the UK are ready to help you prepare for a reliable and productive start to 2026.