Wyma Solutions

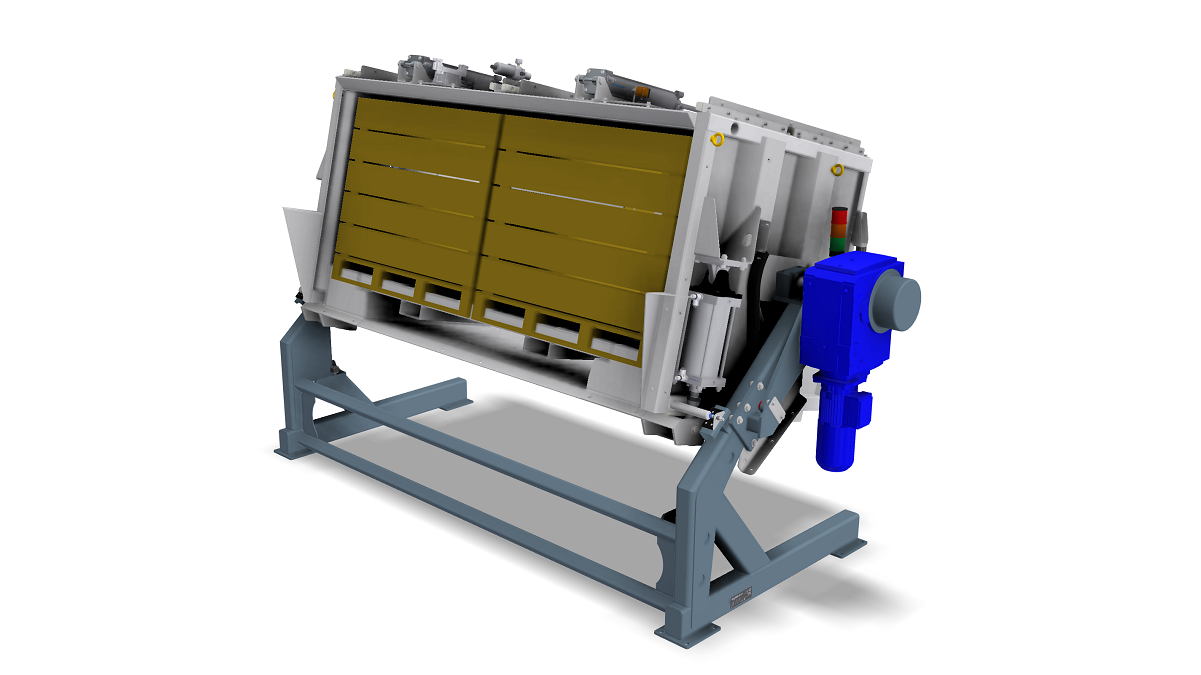

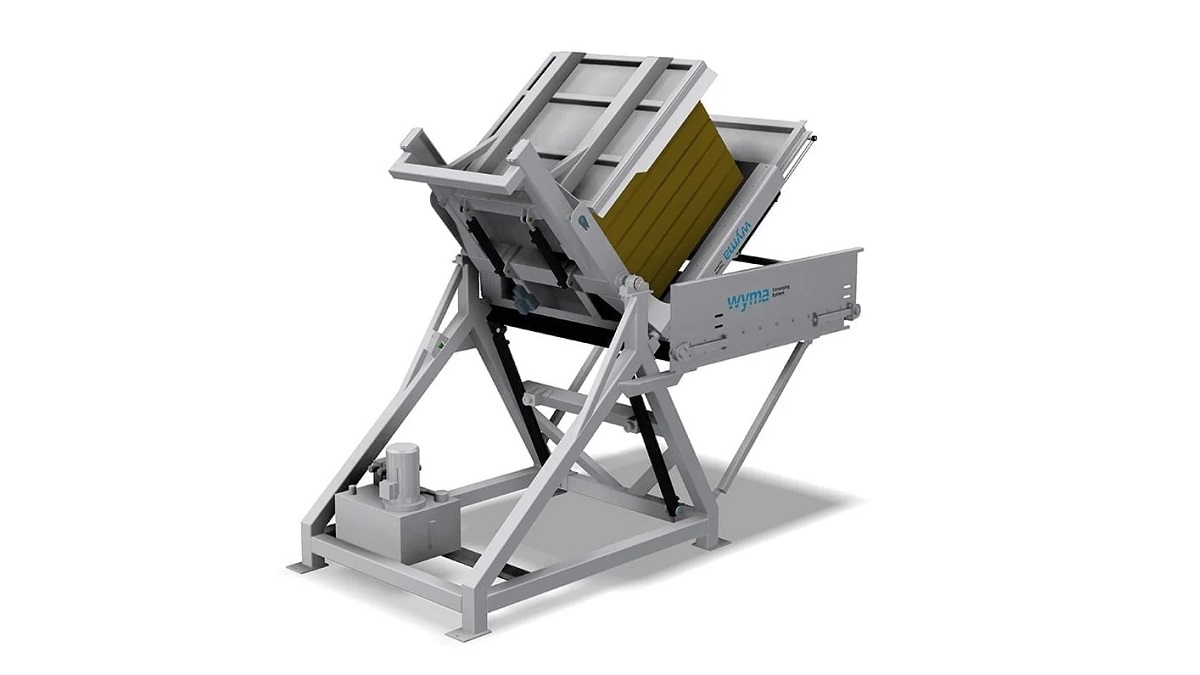

Conditioning

Wyma Drives Postharvest Revolution at Patatas Meléndez with a World-Leading Industry 4.0 Facility

Patatas Meléndez and Wyma have joined forces to create one of the most advanced potato processing plants in the world, setting a new benchmark in efficiency, sustainability, and postharvest innovation

Patatas Meléndez, Spain’s leading fresh potato supplier, has redefined what’s possible in post-harvest handling — building one of the most advanced, fully automated potato processing facilities in the world.

Driven by a bold vision to maximise efficiency, quality, and sustainability, Patatas Meléndez partnered with Wyma to design and implement a high-performance wash line and key packing components. The result is a world-class Industry 4.0 facility that’s setting a new benchmark across the European market.

From the beginning, the company set out to create a smart, digitally connected line that would handle potatoes with the care of fruit — while also delivering measurable gains in productivity and resource use.

A Smart Line with Measurable Results

The new facility at Medina del Campo is now fully operational and already delivering impressive results:

-

Packaging capacity has doubled to 130 pallets per hour

-

AI-powered sorting ensures consistent product quality and accuracy

-

Real-time monitoring gives operators full visibility and control

-

Water and energy use have been significantly reduced

-

Intelligent maintenance systems help prevent downtime and extend equipment life

Explore the Full Story

This transformation is more than just a line upgrade — it’s a long-term strategy built on collaboration, integration, and future-focused thinking.

If you’d like to learn more about the approach, the technology, and the results behind this world-class facility, you can read the full case study below: Read the full case study