Felix Instruments

Measurements

Innovative Hurdle Technique: Extending Fresh-Cut Vegetables' Shelf Life with Vacuum Precooling and MAP

Fresh-cut leafy vegetable’s quality and shelf-life are affected due to enzymatic browning. The hurdle approach of commercial vacuum precooling in combination with modified atmosphere packaging was tested and found to be successful in frillice iceberg, romaine, and red oak.

Minimally processed or fresh-cut leafy vegetables are prepared with methods by physical modifications such as trimming, cutting, washing, rinsing, and packaging that subsequently move along the commercial processing or are stored in cold storage conditions for a short period [1] (*).

According to their convenience and nutritional benefits, fresh-cut salads are ready-to-eat products with a growing market share and are increasingly popular with consumers. The most popular fresh-cut product is fresh-cut salads, both single and blended. For example, approximately 19.4 million Italians consumed ready-to-eat salads in 2017, so ready-to-eat salad growth is up 4% when compared with the year 2016 [2].

Lettuce (Lactuca sativa), known as a salad, is consumed worldwide for the purposes of promoting well-being and preventing or reducing chronic diseases. It is also known as being a good source of vitamin A, C, E, K, folate, carotenoids, and phenolic compounds especially phenolic acids and flavonoids [3].

Food losses of fresh-cut products

Fresh-cut products contribute to food loss and waste of approximately 1.3 Gigatons or 33% of global food production [4], which has become an important obstacle to be concerned in the food supply chain.

During preparation, the cutting process damages the plant tissues and then induces physiological responses, such as an increase in the respiration rate and ethylene production. This hastens the metabolic rate during the storage period and finally results in the stage of senescence [5].

Breakage of internal compartments allows close proximity and reaction of enzymes and substrates, such as polyphenol oxidase (PPO) and peroxidase (POD) in enzymatic browning reactions and chlorophyllase in chlorophyll degradation [6].

The release of nutrients from damage to the outer layer promotes the growth of microbiological organisms. A high respiration rate accelerates the consumption of O2 in the packages. Then, the change of gas composition leads to the anaerobic conditions, finally resulting in an off-flavor.

During transpiration, wilting is the effect of moisture loss, while perishing is caused by the condensation of water vapor. Both physiological damage and microbiological spoilage affect quality degradation, safety aspects, visual quality, and consumer acceptance [7].

Cold storage and vacuum precooling to prevent losses

Cold storage plays an important role in the preservation of fresh-cut products by slowing down temperature-dependent reactions. The recommended storage temperature for fresh-cut vegetables ranges from 0 to 5 °C, which results in lower respiration rate, enzyme activity, and microbial growth, as well as an increase in bioactive compounds [8].

Commercial vacuum precooling technology has been deployed in the production of fresh-cut vegetables instead of room cooling or forced air cooling. Based on the association between ambient pressure and the boiling point of water, when moisture evaporates from the product, the reduction of product temperature starts. When the amount of accumulated heat is equal to the latent heat of evaporation, moisture evaporates rapidly [9].

In addition to the advantages of vacuum cooling technology, namely rapid cooling, uniform cooling, and extending shelf life, the use of the combined concept for preserving the quality of fresh-cut vegetables for designing new fresh-like fruit products is a prospect of future application for quality and safety of the products.

Vacuum cooling and MAP

The research illustrated that vacuum cooling had an effect on PPO activity and improves the quality of a product at a comparatively lower temperature than the other techniques [10]. Modified atmosphere packaging (MAP), known as an innovative approach to maintain or improve the food quality, safety, and the shelf life [11,12], was reported to have the ability to prolong the shelf life of Chinese kale up to 11 days. It does this by maintaining the texture, flavor, and visual quality as well as preserving the nutritional compounds such as chlorophyll and vitamin C [13].

A high concentration of CO2 (20% maximum) could preserve the chlorophyll content and decrease the membrane oxidation of mitochondria by suppressing the reactive oxygen species (ROS) generation [14], while a low concentration of O2 could inhibit enzyme activity as well as retard the growth of microorganism [15].

F-950, Three gas analyzer, CO2 and O2 data in seconds with the Felix Instruments Three Gas Analyzer

F-950, Three gas analyzer, CO2 and O2 data in seconds with the Felix Instruments Three Gas Analyzer

Aims of the study

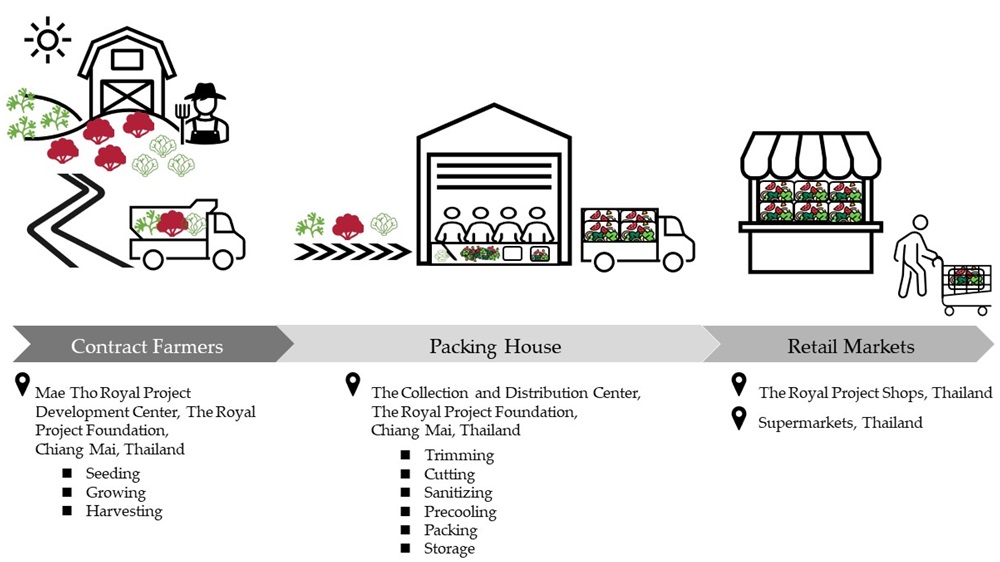

This study aimed to explore the most appropriate hurdle technologies for delaying enzymatic browning and extending the shelf life of fresh-cut vegetables, employing commercial vacuum cooling in combination with modified atmosphere packaging in the supply chain of the Royal Project Foundation in Thailand (Figure 1).

The study emphasizes the potential shelf-life extension of fresh-cut vegetables as they arrived at retail stores. Research examined precooling techniques as important factors combined with using modified atmosphere packaging that could delay browning, increase the retail freshness of fresh-cut salad, and maintain the highest quality with the longest practical shelf life.

Designing the appropriate hurdle technologies to extend the shelf life of fresh-cut salad at the retail level was the study goal of this research.

Summary of the results

The hurdle approach using commercial vacuum precooling in combination with modified atmosphere packaging (MAP) as an alternative to the use of chemical preservatives to prevent enzymatic browning, an undesirable attribute that is easily detected by consumers, was investigated.

The hurdle technology exhibited synergistic effects on fresh-cut lettuce, namely frillice iceberg, romaine, and red oak, in slowing down cut-surface browning, maintaining quality, delaying microbial growth, and extending shelf life of salad products at the retail level.

The findings of the study verified the potential of the hurdle approach in delaying the effect of cutting as well as extending shelf life of the product stored at 4 ± 1 °C with 85% RH from three days to nine days with an additional unit cost of 1.05%.

Therefore, our hurdle approach is anticipated as the practice with non-chemical and economical approach in the supply chain of the fresh-cut, leafy vegetables industry.

(*) The references are available in "More information"

More information

Hurdle Approach for Control of Enzymatic Browning and Extension of Shelf Life of Fresh-Cut Leafy Vegetables Using Vacuum Precooling and Modified Atmosphere Packaging: Commercial Application

Warissara Wanakamol, Pratsanee Kongwong, Chaipichit Chuamuangphan, Damorn Bundhurat, Danai Boonyakiat & Pichaya Poonlarp

Horticulturae 2022, 8(8), 745; https://doi.org/10.3390/horticulturae8080745

MDPI, https://www.mdpi.com/2311-7524/8/8/745

Source

FELIX INSTRUMENTS February 2024 newsletter