Felix Instruments

Measurements

What Is an Ethylene Monitoring System and Why Is It Critical for Fresh Produce?

Sensors used to detect ethylene must be sensitive, selective, stable, rapid, and have the required lower limit and detection range

Ethylene monitoring in the post-harvest stages is essential for prolonging the shelf life and ensuring the safety of fresh produce. In a comprehensive article published by Felix Instruments, the essential characteristics to look for in an efficient system for this task are analyzed.

Ethylene monitoring systems (whether fixed or portable) are crucial, given that ethylene, even in minimal concentrations ( ppm), acts as a plant hormone that accelerates deterioration and senescence.

A complete monitoring system consists of several interconnected elements: a central sensor, data collection, processing, and storage, the provision of alerts, and, finally, control mechanisms to regulate gas levels.

The ethylene sensor is the core component and must meet strict technical requirements: it must be sensitive, selective, stable, and fast, with the capacity to detect minimum levels, down to parts per billion (ppb). To achieve this accuracy and reliability, electrochemical detection is currently highlighted as the preferred standard technology in these systems

The Need for an Ethylene Monitoring System

Ethylene (C2H4) gas is a phytohormone produced by plants in various stages of their growth and development. Its economic value lies in its ability to regulate ripening in climacteric fruits and produce desired traits of color, softness, taste, and aroma. However, it also has adverse effects, as it has a propensity to increase senescence, fruit decay, physiological injury, and pathogen activity of a wide range of fresh produce.

The occurrence of ethylene in the atmosphere, from neighboring fruits and vegetables, or due to burning fuel in machines and smoke, can trigger endogenous production of ethylene in fresh produce, leading to unplanned ripening, spoilage, and decay. So, while ethylene is necessary for ripening climacteric fruits, it is also one of the most significant factors that can reduce shelf life and is strictly controlled in the postharvest phases to extend the shelf life of all fresh produce.

It is widely acknowledged that even trace elements of ethylene of 0.01 ppm–1 ppm can affect the quality of fresh produce. To control the ethylene levels below those harmful to fresh produce, it is necessary to monitor the storage facilities, transport containers, and retailers around the clock. Ethylene monitoring systems should be able to detect gas levels starting from less than one ppb (parts per billion) in real time to quickly control their levels in the postharvest phases of storage and transport, see Figure 1 for possible applications.

Figure 1. “Conceptual framework of ethylene dynamic monitoring enabled multi-strategies control, Wang et al. 2020. (Image credits: https://www.mdpi.com/1424-8220/20/20/5830)

Ethylene Monitoring Systems

The components of a modern ethylene monitoring system should have precise and sensitive sensors to detect the gas, and other technology that can analyze the data and control the gas levels in real time. It should be possible to integrate the sensors into wireless IoT (Internet of Things) systems, providing remote access and allowing for round-the-clock monitoring of fresh produce facilities without requiring staff presence on site at all times. The system can be portable or fixed, but requires miniaturized technology. The elements of the monitoring systems are shown in Figure 2 and are as follows:

Sensors: These include sensors for ethylene and other environmental factors that affect ethylene generation in fresh produce. The sensors collect data for analysis and are part of the IoT.

- Ethylene detectors. The sensors used to detect ethylene must be sensitive, selective, stable, rapid, with high resolution, and have the required lower limit and range of detection.

- Environmental sensors for temperature, humidity, and other gases. Temperature and humidity can affect the generation of endogenous ethylene, so these parameters are also controlled in a facility. Since higher respiration levels increase ethylene production, oxygen and carbon dioxide levels are also measured.

Servers: In an IoT system, staff have remote access to the monitoring system, and it connects the sensors to the interface elements. In many cases, servers enable data logging to inform decision-making by stakeholders.

Interface: The interface module can be an App or a computer that provides warnings, alerts, displays, and manages equipment and control events.

The exact configuration of the three components will differ. However, gas measurement, data collection, analysis, sounding alerts, and controlling events to regulate gas levels and mitigate risks are necessary to produce quality and extend shelf life.

Other factors that can influence the choice of sensors and the monitoring system are the following:

- Cost of instruments, ease of use, and compatibility with current infrastructure.

- Ease of calibration and maintenance to ensure accurate ethylene measurements.

- The availability of reliable technical support from manufacturers and spare parts.

Figure 2. “The framework of the ethylene dynamic monitoring,” Wang et al. 2020. (Image credits: https://www.mdpi.com/1424-8220/20/20/5830)

Ethylene Sensor Characteristics

Several sensors are available on the market, each using a different principle to detect and quantify ethylene gases. The standard technologies are:

- Gas chromatography

- Electrochemical sensing

- Optical sensing (Non-dispersive infrared spectroscopy

Each technology has its strengths and weaknesses, and among the available technologies, electrochemical sensing is the most suitable for ethylene detection due to its accuracy, selectivity, stability, rapid response and recovery, and repeatability. The devices must also be able to operate in the environmental temperatures and humidity that exist in cold storage and transport units for fresh produce.

The choice of sensors for ethylene monitoring should focus on their characteristics, which are discussed below.

Selectivity

Selectivity, also called cross-sensitivity, determines the accuracy of the instrument. It is the ability of the sensor to identify only ethylene among other gases that are present in the atmosphere and avoid cross-selectivity. Ethylene measurements are complicated by the presence of ethanol, ammonia, water vapor, and nitrous oxide in the air. For example, ammonia and ethanol could cause cross-sensitivity in optical instruments as their absorption spectra overlap with that of ethylene. Accurate quantitative measurement of ethylene is not possible when different gases are included in the sensor response. High selectivity is critical in real-time measurement of gases and will improve the reliability of the instrument.

Sensitivity

Sensitivity is the ratio of sensor output change to input change and is determined by the technology used. Since ethylene gas needs to be monitored at ppb levels, the sensors must have high sensitivity to detect and measure these trace levels.

The exact precision required depends on the application, such as quality control or ripening, and can sometimes necessitate measurements of less than one part per billion. Sensitivity is affected by the temperature and relative humidity of the sensors, the length of exposure to gases, and the response time.

Lower Measuring Limit and Dynamic Range

The monitoring system must have the sensitivity to measure the minimum concentrations at which ethylene can affect fresh produce.

Instrument sensitivity can be correlated to the detection range, that is, the difference between the minimum and maximum limits of the gas to be monitored. Some technologies are not equally sensitive to the entire range of measurements required. For example, optical instruments are more sensitive to specific wavelengths than others, and are not reliable for measuring the full range of ethylene that must be monitored. Therefore, it is essential to consider the performance of the technology and the dynamic range, which is the range within which the instrument maintains accuracy, when selecting a monitoring system.

Response and Recovery Time

Response time is the time needed by an instrument to change from zero and reach 90% of its maximum signal after exposure to ethylene, compared to when there is no ethylene in the air. Manufacturers report the response time of their devices as T90.

For real-time monitoring, detection, and analysis to be effective, they must be rapid, especially in dynamic ripening environments, to prevent over-ripening and food loss. Response time will depend on the technology and can take a few seconds to a few minutes.

Recovery time is the time that a sensor needs to return to baseline values of zero after the ethylene source is removed.

Different sensing technologies have varying response and recovery times. For rapid measurements, response and recovery times are crucial, and together, they represent the time required by an instrument from the beginning of a measurement to a state of readiness for new ethylene measurements.

Stability

Stability refers to the long-term stability of the response during the working time. It depends on zero drift and interval drift. Zero drift is the change in sensor output response over the entire working time when there is no target gas or ethylene in the air. Interval drift is the output response change when the sensor is continuously in air that has ethylene, which can often result in a decrease in signal over time. A sensor should be able to have stability even during low-level detection.

A good continuous sensor should have an annual zero drift of less than 10% and remain stable for two to three years under varying conditions.

Operating Conditions

Very high sensor temperatures can damage the instruments. Also, high water vapor in the air reduces sensor sensitivity. So, the instruments should be optimized to operate in the extreme conditions that exist on-site in the fresh produce supply chain.

Calibration

Environmental conditions, long-term use, and aging can all reduce the performance of an ethylene sensor. Sensitivity and response time are most impacted, but so are the other characteristics of a sensor. Moreover, instruments can have sensor discreteness or slight differences in individual instruments from the same producer. Proper and regular calibration can partially remedy these problems. Users should follow the manufacturer’s instructions for calibration.

The Standard Sensor

Among the various technologies available, electrochemical sensors offer the best combination of characteristics and are the standard technology used in ethylene portable and fixed detectors.

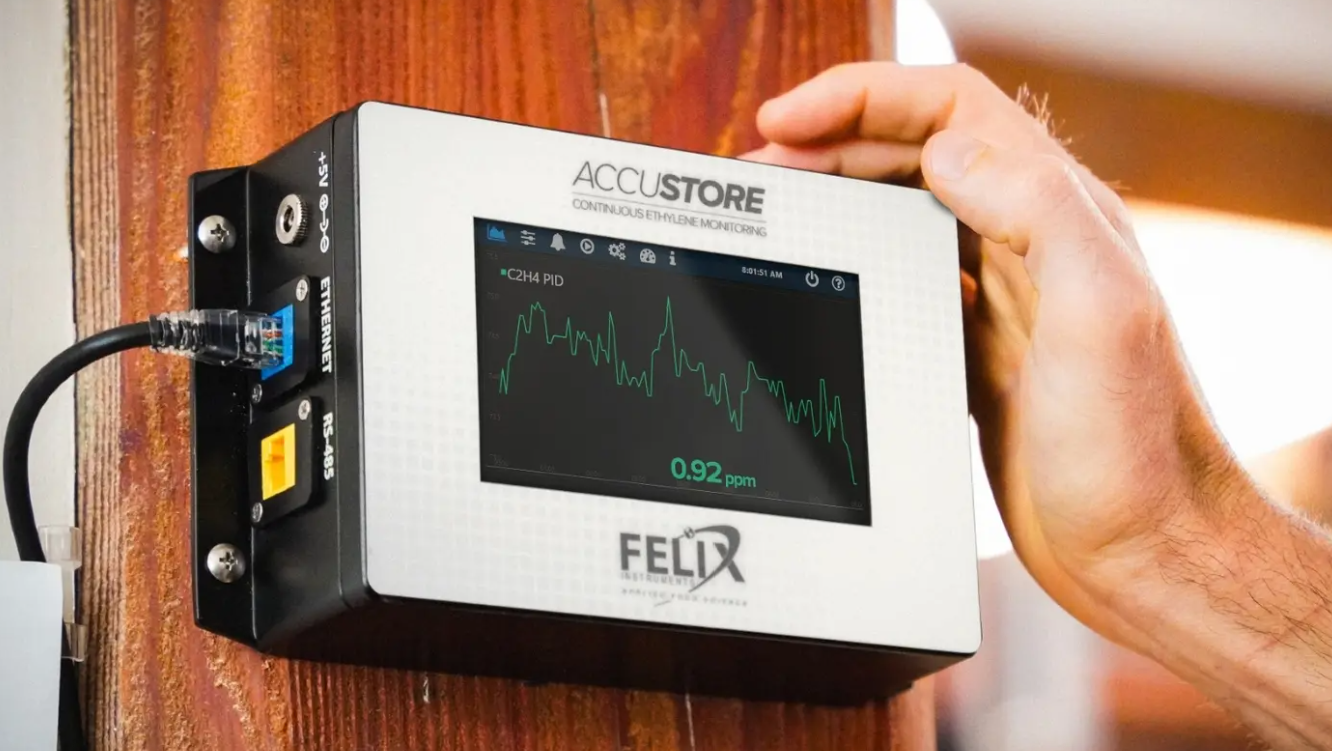

Felix Instruments Applied Food Science offers a range of ethylene detectors, with lower limits and dynamic ranges optimized for various ethylene monitoring applications in the food supply chain. The fixed detectors have a sensor unit and a control unit that can be connected through servers, such as Modbus and Ethernet. The sensor unit has detectors for ethylene, oxygen, carbon dioxide, temperature, and relative humidity. It has more than one interface option, sends sound and email alarms, and has a control event scheduler. The company also offers several portable options for monitoring ethylene.

Find out more about Felix Instruments’ fixed and portable detectors for your ethylene monitoring needs.

About Felix Instruments

Felix Instruments is widely recognized as a global leader in innovative applied food science and produce management technology. They specialize in non-destructive quality control for fresh produce, providing crucial, objective data that helps growers, packers, and handlers optimize harvest timing, manage storage, and significantly reduce food waste.

Their innovative toolset includes specialized NIR (Near-Infrared) quality meters—like the F-751 series—tailored for specific commodities such as mango, avocado, kiwifruit, and grape, which deliver highly accurate, crop-specific measurements. Furthermore, they maintain their edge in gas analysis by having introduced the world's first dedicated 1-MCP analyzer for precise control over this key ethylene inhibitor.

In essence, Felix Instruments provides precise, portable measurement tools, bringing lab-grade data directly into the field and packing house.