Unitec Group

Conditioning

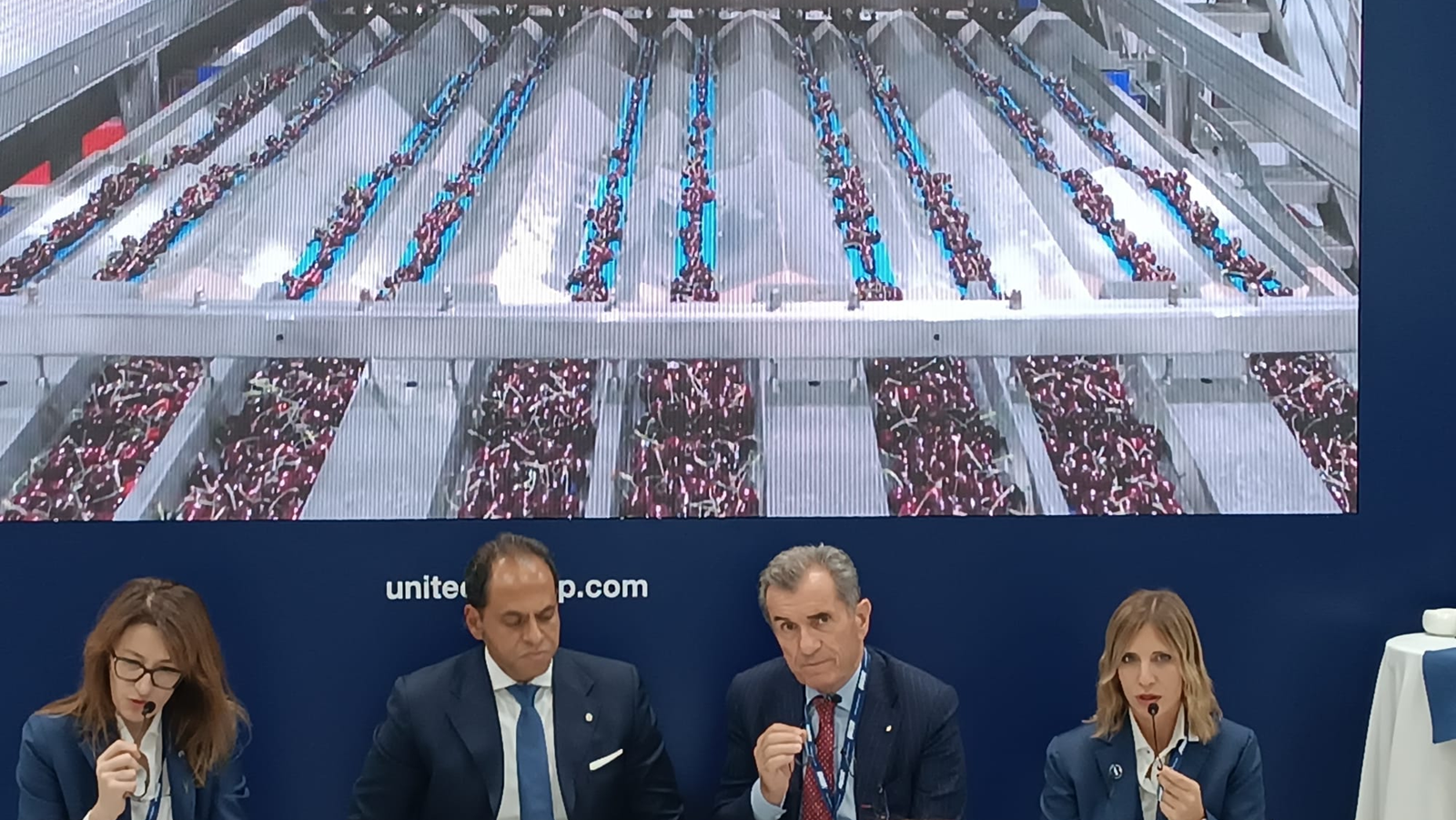

UNITEC brings 100 years of experience to MACFRUT

Many new solutions, fruit of the incessant searching for innovation in connection with the industry

The participation in MACFRUT 2024 is a unique opportunity for UNITEC, as it coincides with the 100th anniversary of the company (1924-2024), and it therefore allows us to celebrate this important milestone. It was 1924 when the first sorters by Dalle Vacche appeared in Massa Lombarda. In this historical company, through the integration of new entrepreneurial experiences, UNITEC has its roots. From the outset, UNITEC immediately stands out for the development and application of new, non-destructive technologies for quality selection of fruit and vegetables, to provide concrete answers to satisfy the needs of fruit and vegetable companies.

This journey, started in the Twenties of the last century, was characterized by research, analysis, and experimentation, and guided by a great passion for concreteness as well as a continuous pursue of perfection, where Customer results are the ultimate goal. “We work for your results”, therefore, as the UNITEC mission declares.

100 years of constant innovation in the sorting and selection of internal and external quality of fruit and vegetables, as well as in all the other handling stages of packing houses, constantly engineering the most modern technologies for the development of solutions that can bring concrete benefits to Customers and that are often characterized by exclusive patents.

An important milestone that frames the participation of the UNITEC Group in MACFRUT, but that constitutes only the first turning point and propels UNITEC towards the future, following its vocation for innovation which is currently represented by the opportunities offered to the produce industry by robotics, from the field to the sales outlet, through the packing houses. UNITEC has already successfully sorted more than 50 types of fruit and vegetables and it is now getting ready to face the next challenges, leveraging the know-how built in a century.

Angelo Benedetti, President of UNITEC, states:

“A hundred years for a company sounds like a long time only when one feels tired and has lost motivation. The incentives that our Customers around the world give us every day, by trusting us, are a long-life elixir for us: we frequently manage to build partnership paths that make us look forward to the next 100 years, to keep giving them Results thanks to our solutions and our continuous innovation.”

Among the innovations presented at the trade show, it is worth mentioning:

UNI SMART TRAY FILLER

Automatic filler which allows to pack different varieties of fruit such as peaches, nectarines, and apples in trays or in trays inside crates. Fruit gathering and placing in trays thanks to an innovative robot with a pick and place function, that can adjust the coordinates of gathering/placing based on the size and format of the package in handling.

UNICAL 244 DATES

Electronic sorter dedicated to handling products of small dimensions, such as damson plums, small tomatoes, jujubes, olives, radishes, chestnuts, walnuts, and dates.

Among the main advantages:

- Considerable cost reduction compared with manual handling;

- Possibility of using unskilled labor;

- Objective increase in handling efficiency;

- Inexpensiveness of mechanical and electronic maintenance costs;

- High performance thanks to the latest generation, easy-to-use software.

UNITEC and UNISORTING UNIQ solutions for internal quality selection dedicated to individual fruits

Many innovations on the internal quality selection systems front, with solutions made entirely by the company's R&D department, dedicated to specific fruits in the UNIQ range (UNIQ Kiwi, UNIQ Apples, UNIQ Peach, UNIQ Plum, UNIQ Blueberry, UNIQ Cherry, UNIQ Orange, UNIQ Apricot, UNIQ Melon, UNIQ Pomegranate, UNIQ Cherry Tomato, UNIQ Pears, UNIQ Avocados, UNIQ Onions, UNIQ Dates, etc.).

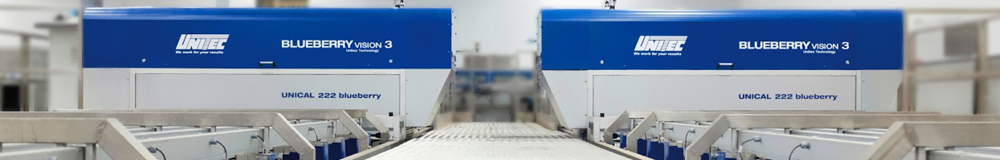

Blueberry sampling machine

UNICAL 222 blueberry is now available with a new design, in the single-lane version, as a sampling machine.

It offers a preview of a product batch, it helps to check the average quality of the batch that comes from different producers and, consequently, to decide how to handle the fruit.

UNITEC innovation never stops. On the blueberries side too, UNITEC constantly innovates.

Indeed, at MACFRUT the UNITEC Group is also present as a PARTNER in the Blueberry Arena. Here, in addition to its solutions for external quality selection, UNITEC presents “taste sorting”; this is possible today thanks to the UNIQ Blueberry solution, entirely designed and developed in-house.

UNITEC at “Red Planet”

UNITEC will also participate in “Red Planet”, the immersive event created by Agroter and MACFRUT to give industry experts a technical and sensory experience on tomatoes, the “red gold”. Indeed, research evidence shows significant consumer dissatisfaction with the taste of tomatoes, especially in terms of quality consistency, and UNITEC solutions can decisively contribute to solving this. The future of tomato quality goes through single-fruit selection, to be able to subdivide the different sensory profiles of the products, in line with consumers’ perception.