Wyma Solutions

Packaging

From Infeed to Packaging: Complete Line Solutions Built Around You

Wyma full line solutions bring efficiency, gentle handling, and sustainability together in one seamless system. From infeed to packaging, we design lines that deliver lasting value and the best from every harvest

For many growers and processors, this is a crucial time for planning and investment decisions. With rising labor costs, pressure from retailers, and increasing environmental demands, choosing the right equipment partner has never been more important.

Wyma offers more than single machines. We design, build, and integrate complete line solutions that help processors of every scale improve efficiency, product quality, and long-term profitability.

What Full Line Solutions Mean

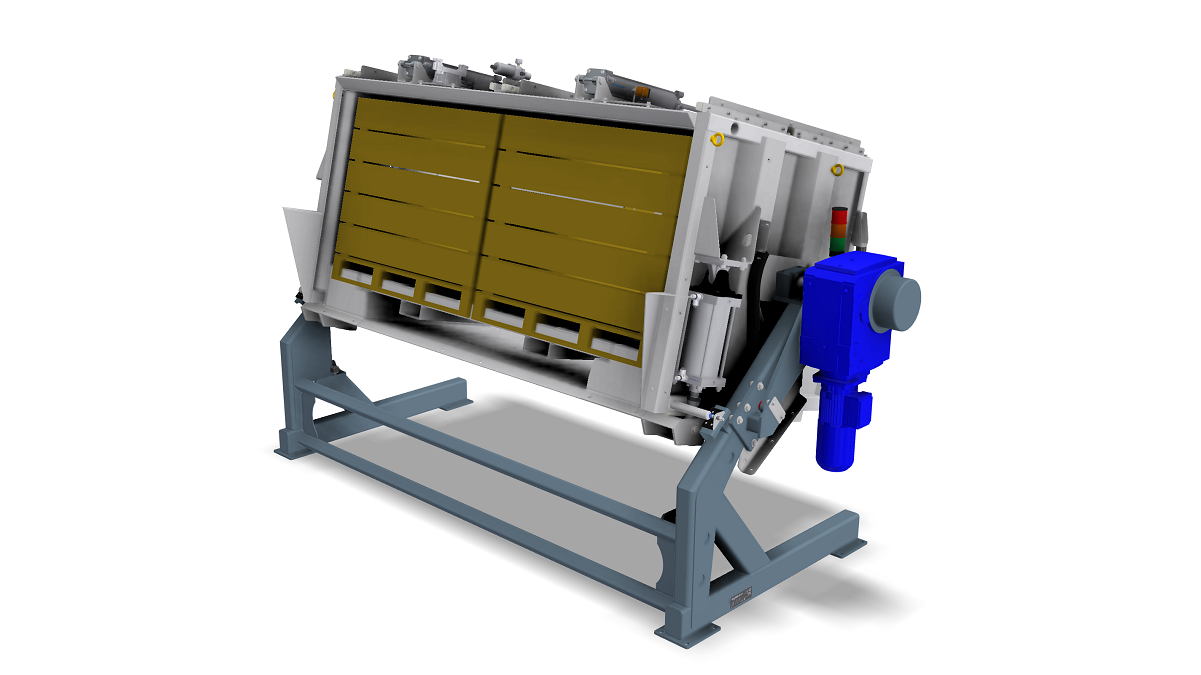

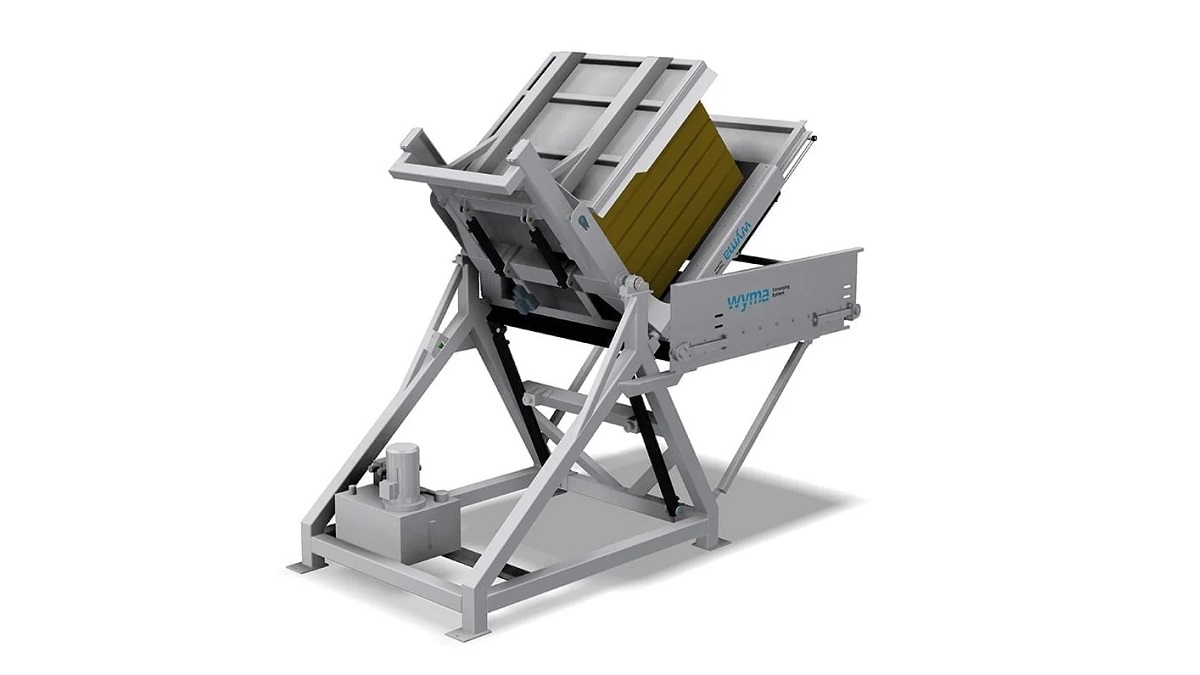

A Wyma full line solution covers the entire journey from infeed to final packaging. Each system is tailored to the unique needs of the processor, whether they handle carrots, potatoes, onions, or other root crops. Our solutions combine Wyma’s proven equipment with trusted technology from specialist partners, creating seamless integration that delivers reliability and measurable results.

Why Choose Wyma for Full Line Solutions?

- Tailored design. Every line is modelled to fit site-specific requirements, using tools like 3D scanning and parametric modelling to make the best use of space and resources.

- Smart automation. Our systems reduce reliance on manual labor by incorporating automated handling, optical grading, and efficient flow management.

- Sustainability. Energy and water efficiency are built into every design, helping customers meet both environmental targets and cost objectives.

- Continuous innovation. With hundreds of product improvements each year, Wyma ensures solutions remain at the forefront of global post-harvest technology.

- End-to-end project management. We handle the full process, from consultation and design through installation, training, and compliance.

- Local support. Our support capability spans the world, with dedicated offices across Europe, UK, Australia, and New Zealand, an established service partners in Americas and Asia. No customer is too far away.

Solutions for Every Processor

From small family-run operations to the largest corporate processors, Wyma has designed and delivered complete line solutions across carrots, potatoes, onions, parsnips and more. Each line is configured to match throughput requirements and processing goals, balancing efficiency with gentle handling so produce retains its quality throughout the process. Explore our full range of line solutions here: Wyma Line Solutions.

Proven in the Field

Wyma full line solutions are trusted by leading processors worldwide.

- Patatas Melendez (Spain) partnered with Wyma to create one of the most advanced potato processing facilities in Europe, built around automation, efficiency, and gentle handling.

- Frederick Hiam Foods (UK) became the first company in the world to install a fully automated optical parsnip trimming line, doubling throughput and reducing labour by over 90 percent.

- Rocky Lammattina & Sons (Australia) relied on Wyma to deliver an end-to-end carrot line that increased efficiency and supported sustainable water management.

- Natures Way Foods (UK) integrated Wyma technology into its carrot processing operations, improving product quality and enabling reliable, large-scale supply to major retailers.

These projects show how Wyma delivers tailored solutions that integrate seamlessly with customer operations, whether for potatoes, carrots, or parsnips, across Europe and beyond.