Wyma Solutions

Conditioning

Smart, Sustainable, and Efficient: Inside the New Patatas Meléndez Plant

Patatas Meléndez is redefining potato processing in Europe with a fully automated, AI-driven post-harvest facility designed to boost efficiency, ensure top quality, and promote sustainability

Patatas Meléndez, Spain’s leading fresh potato supplier, has partnered with Wyma to create one of the most advanced Industry 4.0 post-harvest facilities worldwide. The state-of-the-art plant integrates AI-driven sorting, real-time data monitoring, full automation, and intelligent maintenance systems. This innovative collaboration sets a new standard in the potato industry for efficiency, product handling, and digital integration.

A Vision to Lead Europe’s Potato Sector

Patatas Meléndez stands at the forefront of potato cultivation, selection, and distribution in Spain, driven by a bold ambition: to lead the European market. With a strong foundation in innovation and technology, the company set out to transform its operations by building a fully automated, digitally integrated post-harvest facility in Medina del Campo. The objective: to handle potatoes with the same care as fruit, while maximizing efficiency, quality, and sustainability.

Project Overview

To bring this vision to life, Patatas Meléndez collaborated with a select group of technology partners. Among them, Wyma was chosen to supply and integrate a tailor-made wash line along with critical components of the packing line—ensuring seamless performance, gentle handling, and full compatibility with the facility’s smart infrastructure.

Wyma delivered

- Tailored turnkey line design based on production, product, and data requirements.

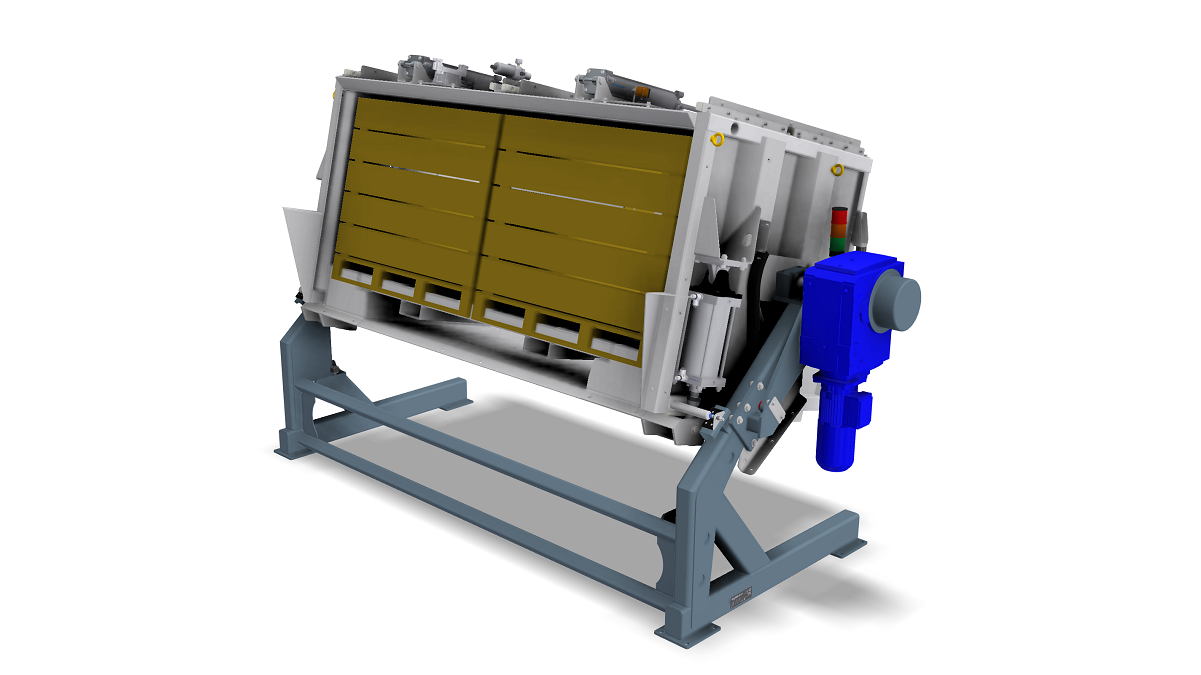

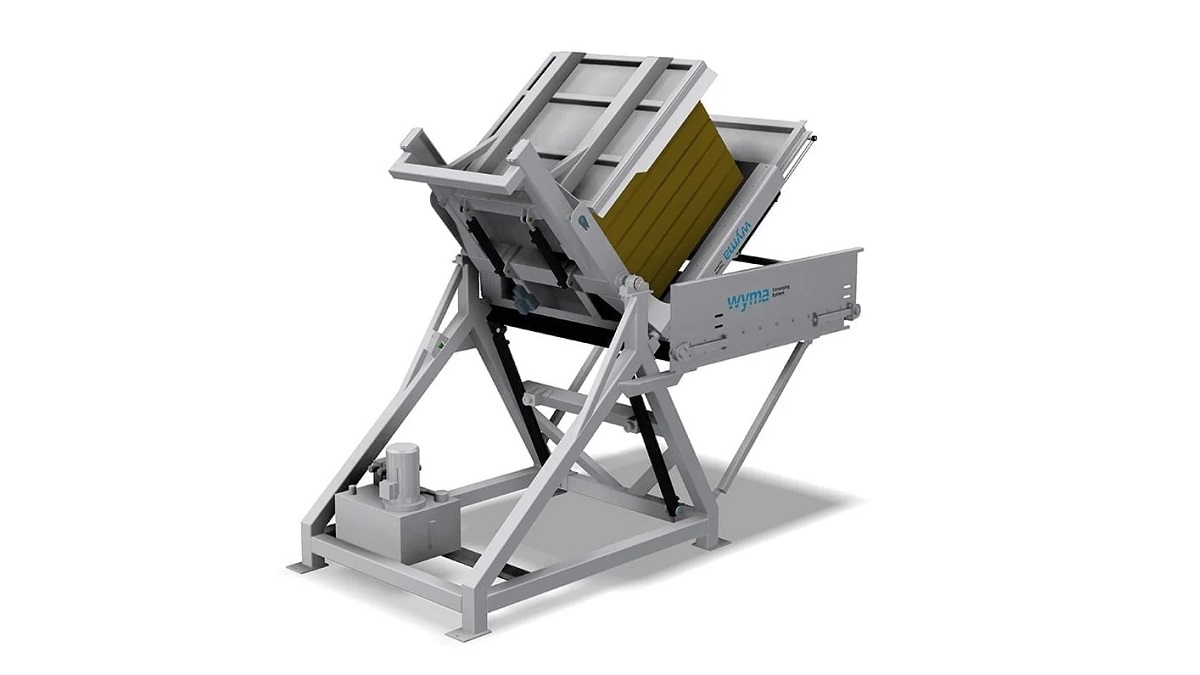

- Gentle handling equipment including washing, drying, and optical grading systems.

- Smart automation to reduce manual labour and maximise traceability.

- Seamless installation and commissioning with on-site and remote support.

- Ongoing technical service and spare parts supply.

Key outcomes

- Packaging capacity doubled from 65 to 130 pallets per hour.

- 17% reduction in energy consumption.

- 30% reduction in water use through recycling and treatment systems.

- Improved worker safety and lower accident rates.

- Enhanced product quality with minimal handling damage.

- Real-time data insights to optimise field-to-factory decision making.

The Challenge

Operating within a traditionally fragmented industry, Patatas Meléndez faced the complex task of modernising its processes to set a new benchmark in European potato processing. The company aimed to reduce operational costs, enhance efficiency, and ensure consistent product quality, all while upholding its commitments to sustainability and workplace safety.

The Solution

Wyma partnered closely with Patatas Meléndez, engaging teams across engineering, quality control, and IT to co-design a solution tailored to the company’s integrated vision. The result was a fully automated processing line incorporating:

- Low-impact transport systems using water channels and gentle conveyors.

- AI-powered optical sorters for precise, automated quality grading.

- Smart packaging and palletising lines for streamlined logistics.

- Built-in digitalisation to enhance traceability, real-time monitoring, and rapid response capabilities.

- This collaborative approach ensured that every element of the line aligned with Patatas Meléndez’s operational goals and long-term strategy.

A Benchmark for the Industry

Patatas Melendez’s new plant is now one of the most advanced in Europe—and possibly the world. With 14 packaging lines, two fully automated washing lines, and built-in artificial intelligence, the facility combines scale with precision. It’s a showcase for what the future of potato processing looks like: smart, sustainable, and deeply connected.

Francisco Javier Pérez, Engineering Director, declared:

“This is the most efficient potato processing facility in the world—and Wyma has been a key part of that achievement.”

Looking Ahead

The partnership doesn’t end here. Patatas Melendez plans to further expand its washing and packaging capacity and is exploring new markets across Northern Europe and Asia.

Javier Meléndez, CEO of the company, said:

“We’ve built in space for growth, and we see Wyma as a long-term partner in that journey."

Source

Cover Image: El Día de Valladolid