Wyma Solutions

Conditioning

How to prevent carrot silvering

Wyma explains techniques to maintain carrot quality from field to table, with an emphasis on preventing silvering

What’s really behind that pale white color on carrots? In this article, Wyma explores the causes of silvering, explains why it matters and outlines how processors can reduce its impact through smart postharvest handling and equipment selection.

Why silvering matters

Carrots may be a commodity crop, but small differences in postharvest handling can have a big impact on product quality and market value. One of the most common visual defects is silvering—the white blush or scaling that appears on the carrot surface due to dehydration of the periderm.

Though harmless, silvering lowers shelf appeal and can reduce sale price, especially in premium retail channels. In a margin-sensitive environment, minimising this visual deterioration is key to protecting both brand reputation and profitability.

What causes silvering?

Silvering is caused by dehydration of the carrot’s outer skin (periderm) after harvest. Several key factors contribute to the rate and severity of this effect:

- Temperature and humidity: High temperatures and low humidity speed up moisture loss. Even in cold storage, poor temperature control or uneven cooling can lead to localised dehydration.

- Respiration and field heat: Carrots respire after harvest, using up water and generating heat. If field heat isn’t removed quickly, dehydration accelerates. Fast cooling is essential.

- Mechanical handling: Brushing, polishing or rough handling can damage the skin and increase water loss. Equipment settings must be fine-tuned to avoid micro-abrasions.

- Varietal susceptibility: Some carrot varieties have thinner or more porous periderm layers, making them more prone to silvering. Postharvest strategy should match varietal characteristics.

- Airflow and storage design: Inconsistent airflow in crates or bins creates microclimates. Carrots near vents may dry faster, leading to uneven product quality across the batch.

- Processing delays: The longer carrots sit between harvest and washing, the more dehydration occurs. Controlled holding conditions can reduce this risk when immediate processing isn’t possible.

Nine practical measures for preserving carrot quality

- Harvest during cooler periods to slow moisture loss and reduce field heat load.

- Rapid cooling postharvest to below 5°C within 24 hours. Vacuum or hydro-cooling offers uniform results at scale.

- Use shade and intermittent water spray during delays between harvest and washing to limit desiccation.

- Maintain the cold chain from pre-cooling to transport and supermarket display.

- Use liners during storage and transit to reduce dehydration, while monitoring for sweating or rot.

- Hydro-cooling or vacuum cooling removes field heat quickly and evenly.

- Polish completely and consistently to remove the periderm. Avoid over-processing that exposes inner tissue.

- Store at 0–4°C with 95–100% humidity and strong air circulation to maintain stable microclimates.

- Harvest at optimal maturity to reduce postharvest stress. Overmature carrots are more prone to dehydration and decay.

Beyond the basics

Advanced growers are also exploring modified atmosphere packaging (MAP) and semi-permeable films for short-term storage, especially in high-value retail segments. These technologies can reduce oxidative stress and maintain higher relative humidity around the product without inducing condensation.

In regions with extended cold storage, some growers have trialled intermittent misting systems to stabilise humidity and reduce respiration peaks during pull-down periods.

There is also growing interest in postharvest calcium dips or coatings that act as a physical barrier to moisture loss. While more common in fruit, experimental trials on carrots have shown early promise in reducing the rate of dehydration and delaying the onset of silvering under ambient display conditions. However, regulatory compliance and residue thresholds must be considered for these approaches.

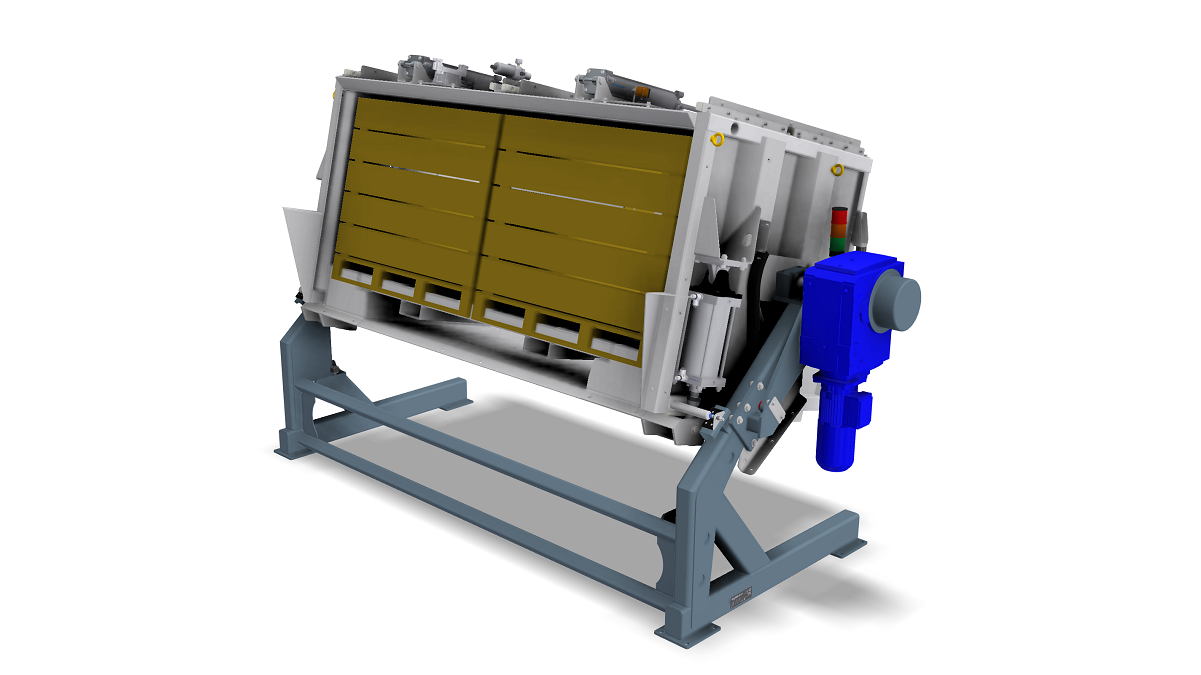

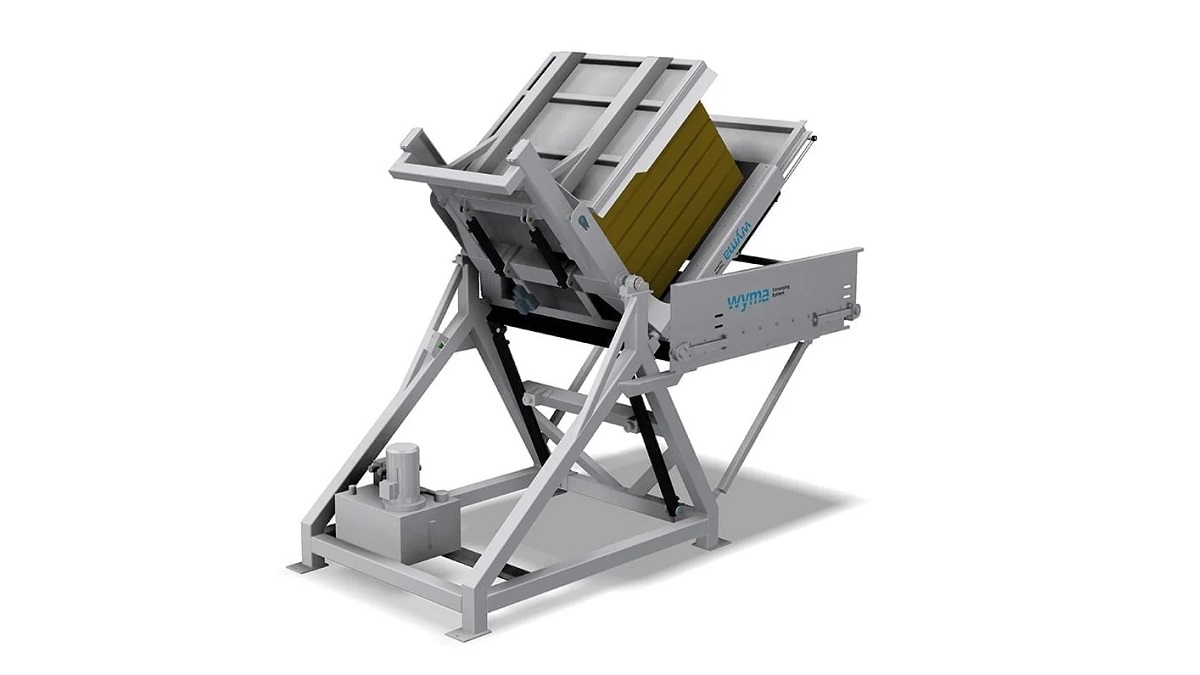

The role of processing equipment

Even with excellent field practices, processing equipment plays a defining role in how carrots present at retail. Washing and polishing must strike the right balance—gentle enough to avoid micro-damage, but thorough enough to remove the periderm that can later silver.

Wyma equipment is designed for this kind of precision. Operators can adjust speed, pressure and polishing intensity to suit different varieties, soil conditions and seasonal variables. Integrated cooling and drying stages help stabilise product condition before packing.

The Wyma team works closely with customers to tailor each system to their needs. From technical consultation through to commissioning, their knowledgeable staff supports processors in reducing silvering, improving pack-out consistency and lowering postharvest losses.

Innovation in optical grading

Emerging grading technologies now go beyond size and shape. Advanced systems use hyperspectral imaging and surface moisture profiling to identify early-stage dehydration—before it’s visible to the eye.

For high-throughput operations, this enables better control over retail appearance and allows vulnerable product to be diverted to alternative processing channels before value is lost.

Closing the loop

Silvering might seem cosmetic, but its effect on quality perception and food waste is significant. Addressing it takes more than just cooling and polishing—it requires an integrated approach across harvesting, storage and processing.

Wyma supports growers and processors at every step, helping ensure their lines deliver optimal quality and maximum return from every harvest.

Want to dig deeper into the technical detail or explore specific challenges in carrot processing

Download WYMA’s free guide or contact their sales team to discover how silvering can be reduced and postharvest performance improved.

Download the whitepapaer: “Get the Best Out of Your Carrots – A Guide to Reducing Silvering and Boosting Quality”