Wyma Solutions

Processing

Iberica de Patatas Enhances Throughput and Quality Without Production Stops

Learn how Iberica de Patatas upgraded to an integrated Wyma solution, boosting throughput, improving consistency, and cutting costs without halting production. A family business embraces automation and efficiency, without stopping production.

Iberica de Patatas, one of Spain’s leading potato suppliers, recently partnered with Wyma to modernise an ageing processing line at their Mercamadrid facility in Madrid, Spain. With a clear focus on increasing output, improving product consistency, and reducing costs, the project was carried out while operations continued 24/7.

Meeting Today’s Demands in a Traditional Industry

With more than 50 years of experience, Iberica de Patatas is deeply rooted in the Spanish produce industry. From supplying supermarkets and traditional markets to working directly with farmers and the HORECA sector, they’ve built a reputation on quality and adaptability.

But the challenge of maintaining consistent product quality year-round—while controlling costs and reducing waste—led them to seek a smarter solution.

The Challenge: Efficiency Without Interruption

Their existing line was outdated and increasingly manual in key areas. Iberica de Patatas needed to upgrade the line to meet today’s production demands but couldn’t afford a full shutdown during installation. The new solution had to fit within limited factory space, support continuous operation, and offer faster throughput with less waste.

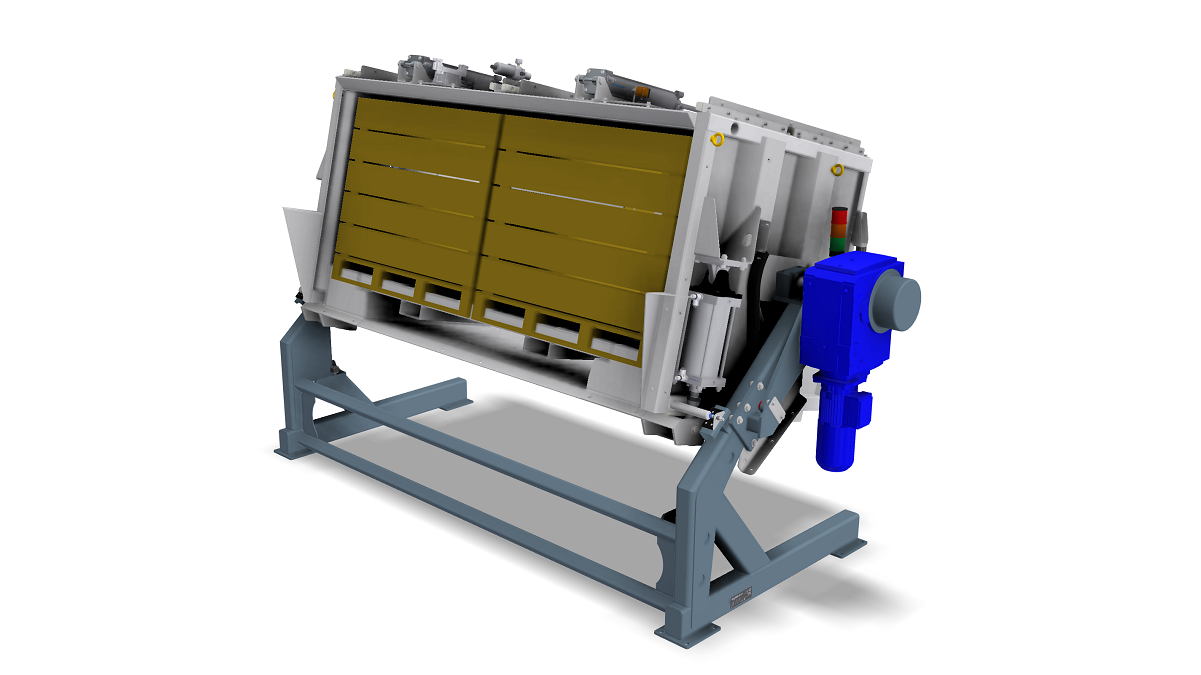

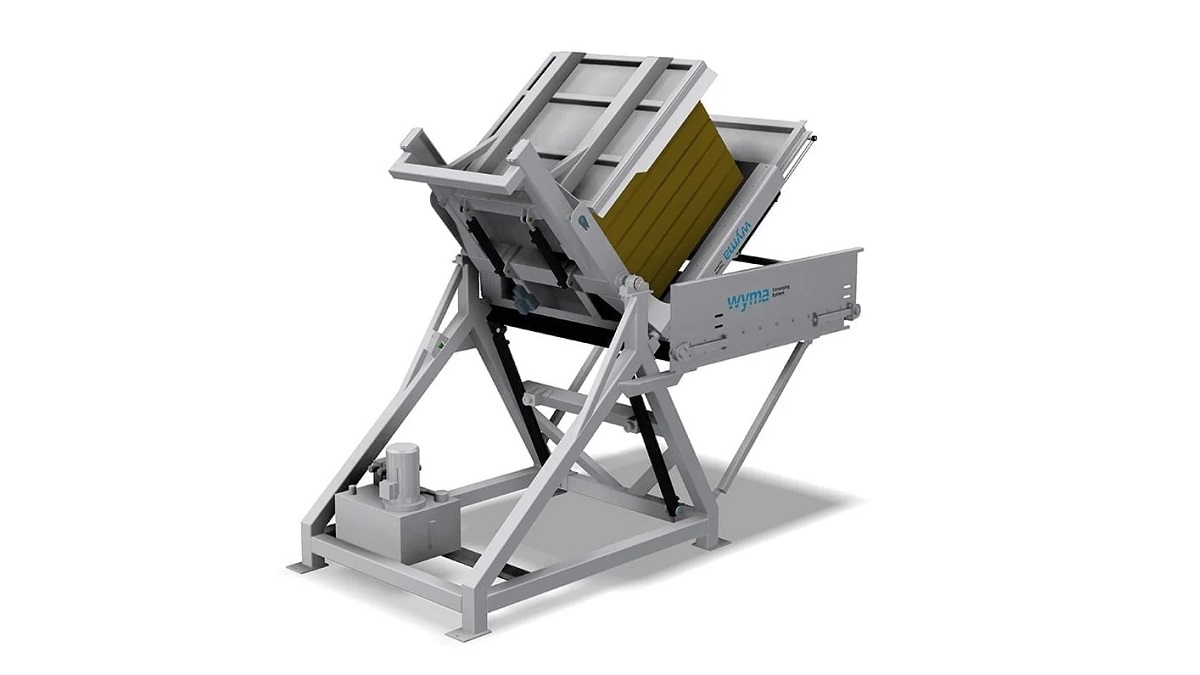

The Solution: A Custom Wyma Line with Local Support

Wyma delivered a fully customised processing solution that not only fit the physical layout but also the operational realities of the business. Key to Iberica’s decision was the availability of 24/7 technical support.

The new system helped Iberica:

- Increase hourly production

- Improve product consistency and visual quality

- Reduce labour, energy, and water usage

- Achieve tighter control of product waste

Pablo Jiménez, CEO of Ibérica de Patatas, declared:

“For me, the most important outcomes have been the quality of the final product and the productivity we’re achieving… and also the reduction in staff.”

A Platform for Growth

Thanks to the success of the installation, Iberica has already designed a third line for future implementation. The project has strengthened the relationship between the two companies, with Wyma seen not just as a supplier—but as a long-term partner.

Jiménez added:

“Wyma is a company you can work with hand-in-hand, to collaborate and grow.”

Source: Cover Image, Wyma