We are the Postharvest Community

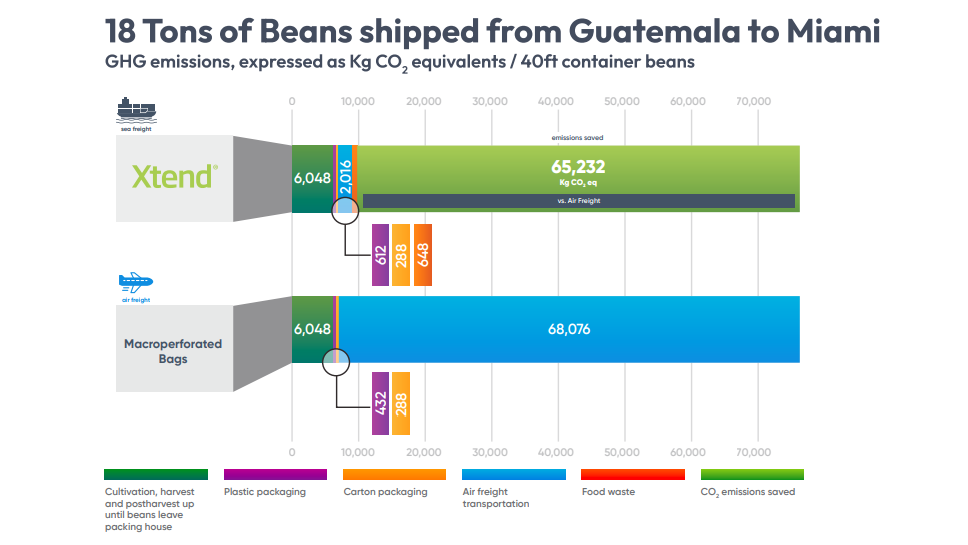

Packaging

Measurements

Companies

TAKE PART?

Applications.png)